The right tools…

To make any project go smoothly as well as get the job done right, requires using the right tools. With the right tools you can get the details of the project just right and the parts all in the right places. That makes any task easier and more enjoyable.

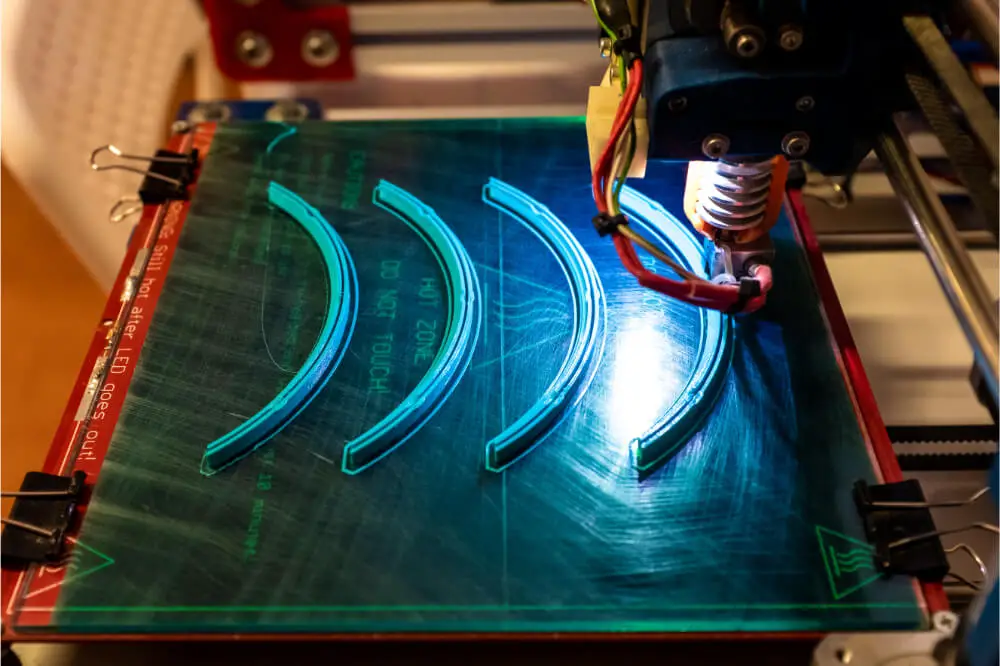

3D scanning is one of those right tools and lets you 3D print just about anything you own. There are just drawbacks to the process that slow down 3D scanning and printing.

To find out if 3D printers can scan objects just continue to read our article. It has the facts you need to know about so you know what to do when the situation arises for you.

Can 3D printers scan objects

Technically, 3D printers are designed to print only. To scan an object you need the scanning accessory, and there are some good models out there to use, then once you scan you transfer the file to the 3D printer and it will print the object for you.

The process is much like the 2D printing and scanning process where you send the digital file to the printer which in turn prints the document but the printer itself does not do the scanning. It needs a scanner tool to do that part.

The steps to 3D scanning

This chart will help you understand the whole process for doing 3D scanning so you can 3D print:

| Steps | Explanation |

|---|---|

| #1. Prepare the object | Spray a temporary matte coating over the object. This will improve scan accuracy |

| #2. 3D scan the object | You need a good 3D scanner to handle this and a table top model is the best one to use |

| #3. Edit the mesh | Scanners provide large mesh files which you need to edit to make sure all following steps go smoothly |

| #4. Import the mesh file | You are moving it to a CAD software that is equipped with reverse engineering tools, make the necessary scan adjustments |

| #5. Extract the important surfaces | This may take a while as you need to refine surfaces and there are 3 avenues to choose from |

| #6. Integrate new objects | You can create jigs at this step to help construction process |

| #7. 3D print the new design | There is better accuracy at this point and you get the object you want |

What you need to know about 3D scanning

Technology is working on this part of 3D scanning but it still has a ways to go before the scanners and printers catch up with the 2D 3 in one model. It is a slow process as 3D printer manufacturers try to put 3D printing and scanning into easier access and user friendly territory.

#1. 3D scanning is behind the times

This is one aspect of 3D printing that is holding the industry back. User friendly software is not where it should be and it is still a little complicated to 3D scan and then print

#2. The cost is still a little prohibitive

It is still all about money and the bottom line is still the major influence when it comes to 3D printing or scanning. Right now 3D scanners are too large and cost too much for individual homeowners to be interested in this part of 3D printing.

There are cheap alternatives but the quality of the scan and print are suspect.

#3. Technology is doing its best

Currently, there are some hand held models available and this technology has made it possible to scan just about anything that doesn’t move or is nailed down. You are looking at paying between $400 and $1200 for one of these models. This is in addition to your printer and material expenses.

#4. Scanners are not just for printing

You can use scanners to help educate students, your children or those adults who want to learn more about butterflies, plants or even motorcycles. The Smithsonian has been doing this for some time now as that institution places their scans online for teachers, etc., to use in their classrooms

#5. Scanners add some usefulness to 3D printers

There are open source websites where you can get the computer file you need to 3D print, but 3D scanning takes printing to a whole new level and lets you scan and print those personal items around your home with relative ease.

Right now 3D printing is in the novelty stage and hasn’t moved that far beyond that stage. Its practical use belongs more in different industries than for home usage.

3D scanning with your phone

This technology has been around since about 2013 and provides you with different apps you can download and then use to scan those objects when you are away from home. Or scan a friend to preserve their look, no matter what you scan you need some tips to guide you:

- Use bright, evenly cast light to make sure you get all the details

- Make sure your models fit your screen and stay at just the right distance away

- Keep your object still at all times and do not scan items that are extremely thin

- Avoid plain objects as they lack good scan details and can create reflections

- When scanning people walk around the model and cover all the angles. Hair may not scan a well as you like

- Use a one color background that is bright enough for the phone app to distinguish between the background and the model

- Like painting a portrait, the model needs to be very still until you are done

- There are lots of phone apps available so take your time and find the right one for you and your phone

Some final words

While 3D printers may not actually do the scanning, you can still do 3D scanning and printing. The key is to find the right 3D scanner that will work with your purpose. Right now the cost may be a bit too high for most people but technology is working on bringing that cost down. It is just a matter of time