For anyone involved in soldering work, having a reliable and efficient soldering iron is a must-have. Making a pencil soldering iron is easy and inexpensive. Armed with the knowledge on easy DIY steps to build your own appliance, soldering will be an even greater joy.

From the comfort home, we will take you through a systematic process on How to Make a Pencil Soldering Iron in three easy steps. If you accidentally damage your soldering iron and need a solution, or simply want to make one as opposed to buying, simple household materials and a bit of knowledge will get you sorted out in no time.

Caution:

As it is with all electrical appliances, you must remember to exercise due caution when working with your pencil soldering iron. These few tips will go a long way in ensuring not just your safety, but also that of others in the vicinity, as well as minimize the risk of damage.

- A soldering iron can reach temperatures in excess of 400°C and is a potential burn or fire hazard.

- Always ensure that the soldering iron is unplugged when not in use.

- Whenever using your pencil soldering iron, always remember to keep your fingers well away from its tip

- In between jobs, ensure that you securely place your soldering iron on its stand or cooling plate.

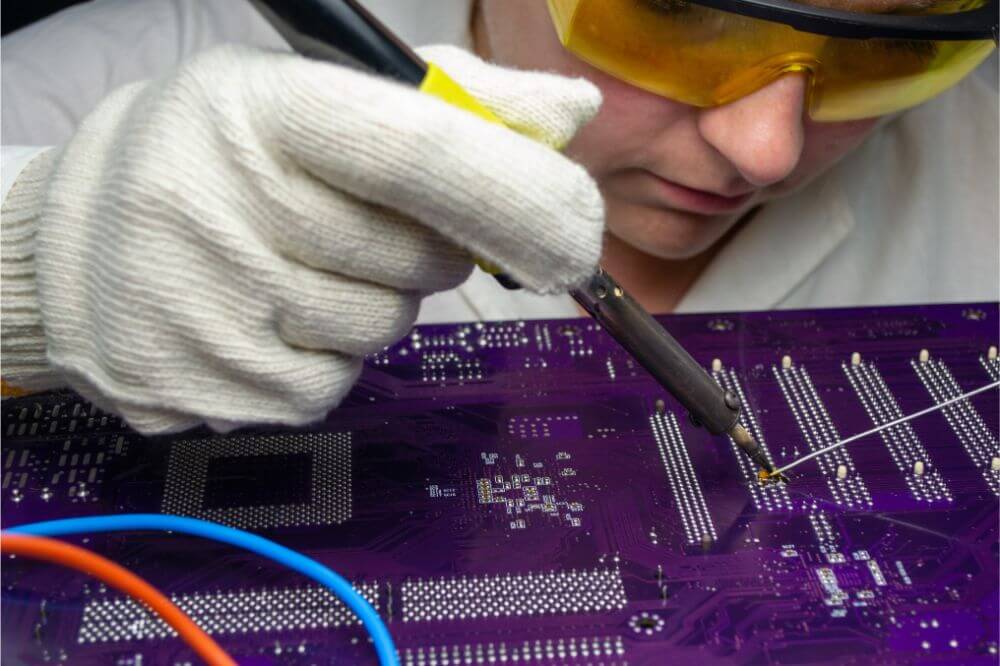

- Wear protective gloves whenever working with appliances that generate heat.

- Ensure your working area has sufficient light and ventilation.

- Whenever possible, wear protective goggles to protect your eyes from smoke and fragments.

- Keep a first aid box handy. Accidents do happen.

- Finally, thoroughly wash your hands after soldering to get rid of possible lead contamination.

1. Step One: Requirements.

Soldering is an essential skill in electronics. Should you require carrying out repairs on your electronic appliances or even creating your own circuit boards, acquiring the necessary skills just requires an instructional Youtube video. A couple of tutorials later, you will be soldering like a pro.

Taking into account that we are going to learn how to make a pencil soldering iron, you should try out smaller hobbyist or beginner soldering tasks such as simple circuit board joints.

The project is simple enough to complete in an hour, once you gather all the materials. Even if you might not have all the required materials lying somewhere, with ten dollars and a quick run to the home depot store, you will be ready to go.

We are going to understand how possible it is to incorporate a pencil, pen and a few everyday components in the making of a cheap yet fully functional pencil soldering iron.

- A flexible or bendable piece of metal

- Heat resistant adhesive and normal adhesive tape

- A pencil

- Power supply unit (PSU)

- A pen.

- A pair of pliers

- A cutting tool such as a utility knife

- Scissors

- Sandpaper or a file

- Some soldering flux

2. Step Two: The Build

Firstly, you will need to use your cutting tool (even a kitchen knife will do) to sharpen the edges of the pencil to expose the graphite. You must be careful not to cause any breakage in the graphite, as it needs to be a single piece to work.

When selecting your pencil, bear in mind that the quality of graphite is your pencil plays a huge role in determining the overall success of your soldering iron. Some types of graphite are more conductive and therefore superior to others.

Attach your wiring.

Use a pen to hold the tip of your pencil by first removing the internal parts to create a hollow tube.

Next, pass your electrical wire through the now hollow pen then wrap a piece of flexible metal ensuring that they form a solid bond.

3. Step Three: All Systems Go

Now that you have created a pencil soldering iron, the next step is to safely attach it to a power supply unit and get soldering.

- To make the heater resistor, attach one end of the wire near the sharp end and wind it over the insulation

- It may take a little experimenting to determine the most ideal wire length.

- For your power supply, select a PSU with at least 30 watts of power. Pencil soldering irons with low voltage not only take longer to heat up, they lack temperature-holding consistency.

- The color-coding on most power supply units is a good guide to knowing which wire goes where. Most PSU covers have written or illustrated color keys.

- Looking next at amperage, choose whichever rail delivers the required temperature for your tip. The general rule of thumb is; if you want to increase the current, you can do so by either decreasing the resistance or upping the voltage. One way to achieve this is by shortening the length of your graphite tip.

- Next, you can now connect the wire from the pen to the rail. In some instances, it takes some additional wiring for the PSU to power on.

- Finally, hold the tip with a pair of insulated pliers and apply DC voltage. Computer PSU’s are particularly great as they have an auto shutdown function in the event of short-circuit.

- To begin soldering, simply touch the graphite tip with your PSU connecting wire and the heating process will begin. The iron will always remain hot when in contact with the graphite tip.

- Continued contact of the graphite tip can cause it to burn. A good way to check this is when you notice it beginning to glow, you can be sure that the pen needs cooling. Fortunately, graphite decreases temperature in a matter of seconds.

Final Thoughts

The slim, lightweight design of a pencil soldering iron gives it ideal access to the hard-to-reach areas. When you need to work on small soldering joints in electronics and electro technical applications, this handy DIY soldering iron makes perfect sense.

Now that you are fully conversant with how to make a pencil soldering iron, you need not ever buy another from a hardware store. As always, enjoy your DIY and remember to keep safe.