3D printing has become popular across the globe as this interactive technology is both easy to use and exciting. There many different types of 3D printers, and the main reasons for these differences are printer speed, printer quality, printer cost, user expectation, practicality as well as printer capability.

Furthermore, some printers print in both graphics and text, whereas others only print in text, and the materials used across these different types of 3D printers vary. Therefore, if you are thinking of buying a 3D printer, you have come to the right place as we will take you through the different types of 3D printing technologies on the market.

Stereolithography (SLA) Technology

This is a fast prototyping process, and you should opt for it if you want precise and accurate results. With it, you only need a few hours to create 3D CAD data (computer-generated) files while still guaranteeing exactness and fine details.

You Might Like: Large 3D Printers for the Family

3D printers that incorporate this technology make unique patterns, prototypes, models as well as numerous production parts. This is achieved by converting liquid photopolymers one layer at a time into firm 3D items. Subsequently, the plastic is heated until it is in its semi-liquid form, and after that, it solidifies on contact.

Additionally, the 3D printer creates every layer by making use of the ultraviolet laser being produced by the Y and X scanning mirrors. The recoater blade typically moves through the surface before every print cycle to spread the resin uniformly across the object. This print cycle carries on until the 3D object has been constructed from the bottom up.

The use of SLA printing has become widely used across many industries such as entertainment, aerospace, medical, automotive, and the making of consumer products as it is economical.

Laminated Object Manufacturing (LOM) Technology

Helisys Inc., a California-based company, is responsible for developing this technology, which is an inexpensive and useful 3D printing technique. This technology works by either laminating or fusing layers of paper or plastic using both pressure and heat, with a computer-controlled laser or blade cutting the objects into the preferred shape.

After every printed layer is finished, the platform moves on to the next layer by moving down approximately 1/16th of an inch. Consequently, the 3D printer pulls a fresh sheet of materials to the substrate, where it is adhered using the heated roller.

However, despite being one of the quickest as well as affordable methods of making 3D objects, it still is not very popular. This technique is cheap since it makes use of low-cost materials that is plastics and paper.

Digital Light Processing (DLP) Technology

It is the oldest 3D printing technology and was created by Larry Hornbeck in 1987, and it works with photopolymers. For you to use this printer, you need to place the liquid plastic resin inside the translucent plastic container.

The source of light for 3D printers using this technology are the traditional arc lamps, which guarantees remarkable printing speeds as the resin hardens faster when exposed to lots of light. Therefore, with DLP 3D printing, you get to achieve faster print times compared to when using SLA.

Moreover, DLP technology is robust, always delivers high-resolution models, and is economical; thereby, it can create cheaper materials from particular and complex items. Consequently, this allows you not only to minimize waste but also ensure low printing costs.

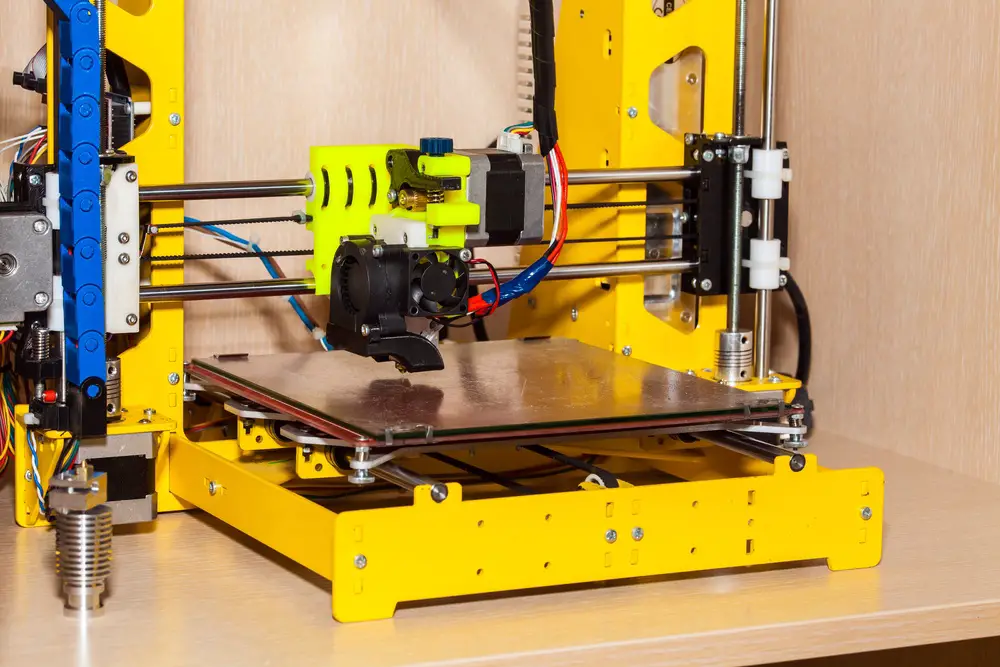

Fused Deposition Modeling (FDM) Technology

This technology was developed during the 1980s by Scott Crump, and to print 3D objects; it uses production-grade thermal plastic resources. Additionally, it is a popular choice for the production of concept models, manufacturing aids as well as functional prototypes. This technology creates items with outstanding strength to work ratio and accurate details.

Objects created using FDM technology are durable and functional; hence, why its use is widespread across numerous industries for part manufacturers and mechanical engineering. Some of the famous companies that use FDM include Nestle and BMW.

Selective Laser Sintering (SLS) Technology

Dr. Carl Deckard invented the SLS technology in the mid-1980s, and this 3D printing technique makes use of high power CO2 lasers to merge particles. Furthermore, whereas the laser sinters crushed metal substances, it can also use several other constituents such as ceramics, glass, and nylon powder.

3D printers using this technology create tough, highly precise parts that can be used in a broad range of materials and is ideal for you if you want end-user prototypes and components that are fully-functional.

Likewise, this technology is relatively comparable to SLS in terms of quality and speed, but the primary difference is that SLS utilizes powdered materials while SLA makes use of liquid resins. Thus, SLA technology is very popular because of its broad range of available materials for custom-built printing items.

Selective Laser Melting (SLM) Technology

This 3D printing technology was unveiled in 1995 and was part of the German research project at Fraunhofer Institute ILT. It also makes use of high-powered laser beams, similar to SLA, to create 3D objects, with the laser beam melting and fusing numerous metallic powders.

With SLM printing, you get 3D parts that feature complex geometries, structures as well as thin walls. Additionally, it is also used in the aerospace industry in several of its innovative projects that focus on durable, lightweight, and precise parts.

However, this 3D printing technology is expensive; hence, why it is not popular or practical for most home users. Therefore, investors in SLM 3D printers often are medical orthopedics and aerospace industries, universities, researchers, as well as metal powder developers.

Suggested: We Recommend these 5 Great 3D Printers

Electron Beam Melting (EBM) Technology

This 3D printing technology was developed by Acram AB, a Swedish company back in 1997. It shares some of its concepts with SLM technology; that is, it makes use of the powder bed fusion method. Nevertheless, the difference between these methods is the power source since EMB utilizes a strong electron beam in the vacuum. In contrast, SLM makes use of high-powered laser inside the chamber of the noble.

The primary use of EMB technology is printing 3D metal parts, with its main attribute being able to create complicated geometrics you can create with much freedom. Additionally, it also creates parts that are amazingly dense and robust in their composition.