Moving parts add to a design…

It makes the print more complicated but it also makes it more interesting. In older 3D printers you had to print the moving part separately from the rest of the object. Today there are 3D printers which can print moving parts in one print task.

This upgrade simplifies the printing process and makes it easier on you. They key to doing this would be to get the right design file so your printed object moves when it is finished.

To learn more about printing moving parts, just continue to read our article. It has the best information possible on how to make moving parts with a 3D printer.

How do 3D printers make moving parts

Not to be obvious or snide about this, 3D printers simply follow the GCode instructions in order to make those moving parts. To create those moving parts you first need a good file that has all the correct instructions and details for the printer to follow.

Then, most importantly, you need to have the right clearances. These measurements need to be exact and need to fit the type of moving part you want on your object. For example, a loose joint may require a 0.3mm clearance while a tighter one requires a 0.1mm clearance.

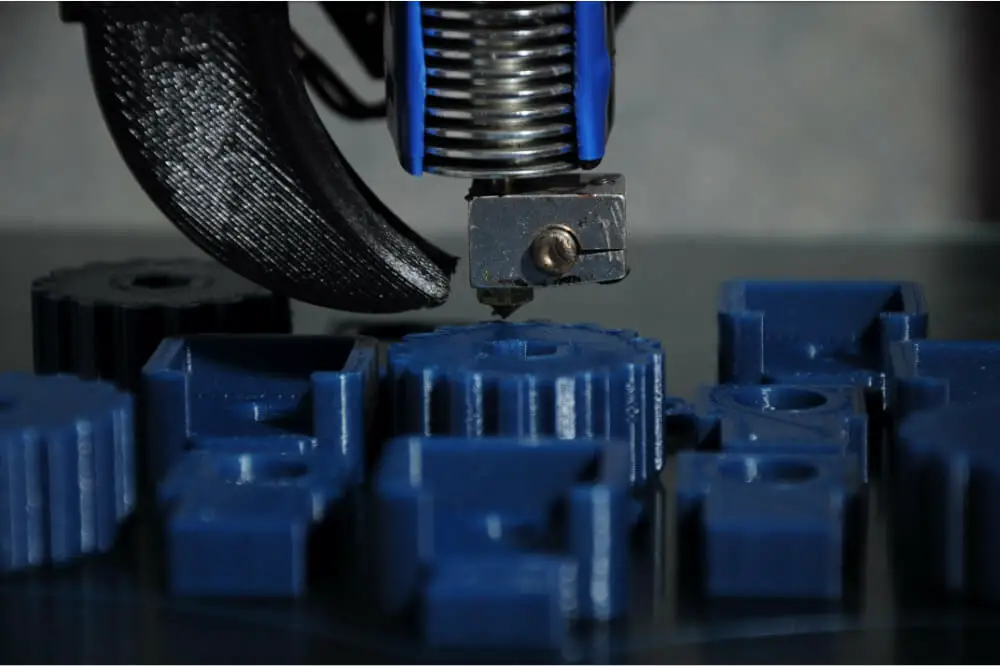

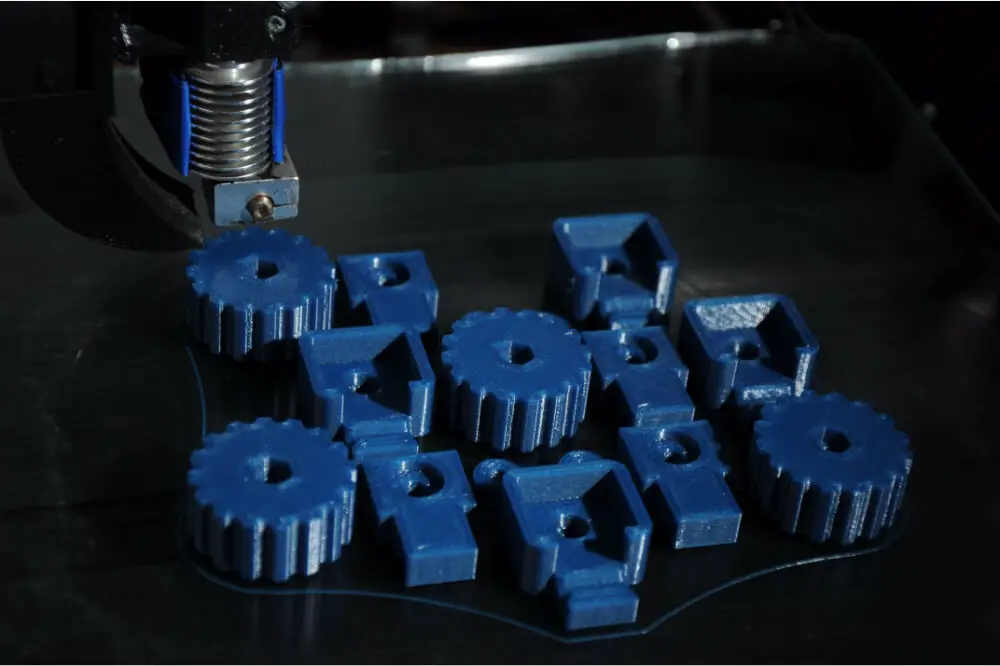

What is happening is that the 3D printer, with the right clearances will print those moving parts as separate objects but all in one print. The clearances will depend on the type of moving part you want to make and if it is hinges, pins or gears.

If you are using holes be aware that those printed holes may not come out perfectly round. Also do a test print to make sure everything will work right and come out like you wanted.

The steps to making a single print with moving parts

It is actually quite simple to make a print with moving parts. The complications come in when trying to create a file to instruct the printer. Here are the steps you need to take:

| Steps | Item | Description |

|---|---|---|

| 1. | Design | This has to include all the specific details you need to build the print as well as all the correct clearance measurements in their correct spot. If you are doing it yourself, this can take hours |

| 2. | Improvement | Once the print has been made, you have to go over it and see what flaws can be corrected. Sometimes the filament material will have too much friction for the moving parts to move, a little spray on lubricant will solve that issue |

| 3. | Decorate | After making the improvements, you can decorate the object any way you wish |

Just be forewarned, making prints with moving parts is not at its all time best and you shouldn’t expect to mass produce any item you 3D print. There are still bugs to work out of the system.

Some 3D printing with moving parts negatives

We all know the best and most important positive that comes with making an object with moving parts. It is a great achievement and a nice reward for all the hard work that went into the project.

However, right now there may be some negatives that will stop some people from trying these projects until 3D printers get better. Here are those negatives:

- You need to be a skilled designer- if you are creating your own object. Drawing the design and then transferring it to a file format takes skilled work.

- Specs are hard to do- you have to get all the measurements right not just those pesky clearances.

- 3D printers are not ready- even higher end printers have a hard time producing precision moving parts.

- Friction is an issue- not all filaments allow the parts to move independently or smoothly.

- Parts do not always move- sometimes the filament is laid out in such a way that the moving parts are stuck. Some people have used light taps from hammers to free them.

- Not all filaments can produce moving parts- right now the metal filaments are having a difficult time doing this and there may be others that can’t do the difficult precise work accurately.

- Technological upgrades are needed- not only to help solve these issues but to bring the cost of printing and printers down to a more affordable level.

What objects with moving parts can 3D printers create

This is not going to be an exhaustive list but the ones mentioned here can be built for free. To get to the files and plans just click on this link. If you have the right 3D printer, you should be able to find that printing individual projects with moving parts is not that hard.

- The Gyroscopic Cube Gears– it is a challenge but the end result is worth it.

- The Walking Pony- delight little children and print them a toy that will entertain them for at least an hour or so.

- Hands for Anny- for those kids who like pretending they are a robot. It is not motorized and needs human fingers to move the plastic ones.

- Sphere-O-Bot (eggbot Mod)- takes the work out of decorating Easter eggs for that Easter egg hunt you have planned.

- Fidget Hand Spinner- this fad may be gone but you can still create one or more just in case someone is still interested.

- Vise & drill- two good tools that are always needed around the house.great toys for kids.

- Robotic woman- every man’s dream. No talking back, does what she is told and looks good at the same time.

Some final words

It seems that 3d printing moving parts is still in its infancy and there is a long way to go before you can do full scale printing of these objects. But for now, you can hone your skills as practice makes perfect.

Then you can use these printed objects as great gifts for children or children wards in hospitals. There is always a good use for what you print even if they do not move.