In the realm of construction and engineering, screws and bolts represent two fundamental fasteners that hold together the world we live in.

Both found ubiquitously, these humble household essentials contribute significantly to building durable structures and ensuring their longevity. However, their interchangeable usage often leads to misconceptions and misunderstandings.

This discourse aims to encourage a lucid understanding of the characteristics and functions of screws and bolts, thereby empowering the enthusiastic hobbyists to make appropriate selections based on the nature of their projects, material type and load specifications. It’s not just about fastening; it’s about making informed choices for sustainable structures.

Understanding Screws and Bolts

Unearthing the Mystery: The Real Difference between Screws and Bolts

Let’s dive into the fascinating world of hardware, where screws and bolts often come up as objects of discussion and confusion.

These two are the rockstars of assembly, having crucial roles in various projects-from small DIYs at home to large industrial constructions. So, let’s unravel the mystery, shall we? Brace yourselves for an electrifying journey that separates screws from bolts!

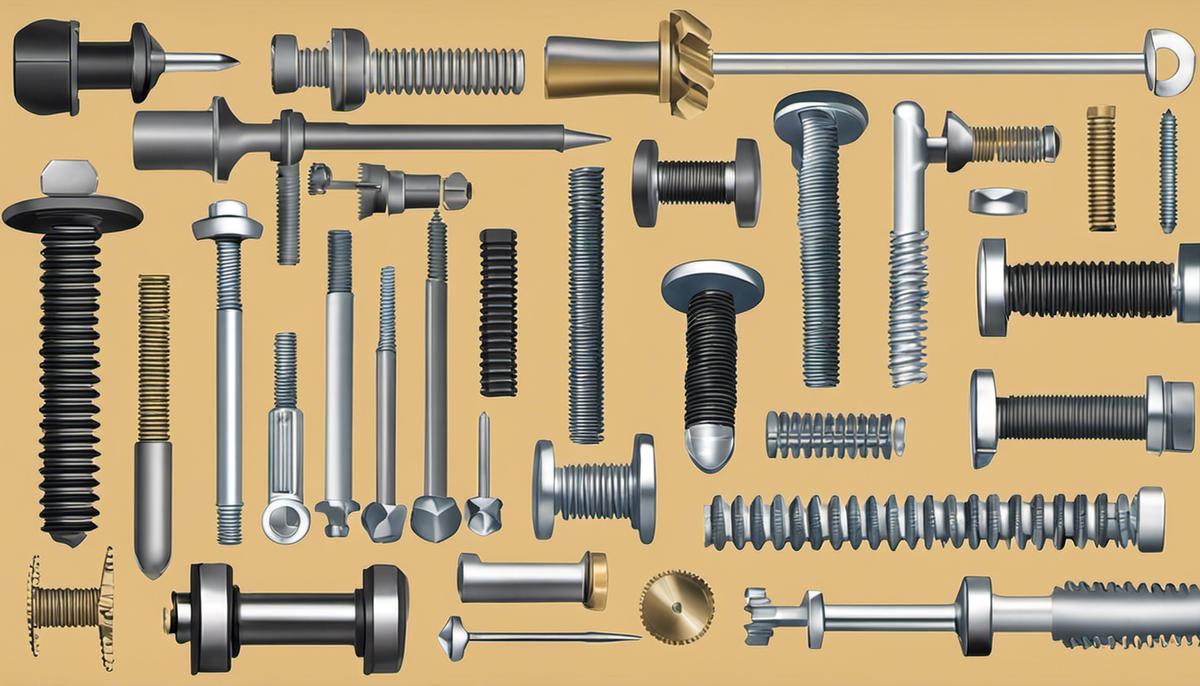

At first glance, screws and bolts might appear the same. Both exist as cylindrical fasteners with an external thread winding around them, but these surface similarities elude to the actual differences in function, application, and design.

Starting with screws, they’re like the unique superheroes of the fastener world – independent and self-reliant. Screws are designed to create their own path, having sharp, tapered ends that create threads in the material.

This ‘self-tapping’ ability means that with a bit of pressure and rotation, screws can make their own way into materials.

Imagine assembling your favorite flat-pack furniture or hanging a picture frame. In such applications, the success lies in the screw’s power to bind materials tightly upon insertion.

This independent power makes screws a favorite choice for woodworkers, interior designers, and many DIY enthusiasts. Also, screws come with different types of drive heads such as Phillips, flat, or square, allowing flexibility when choosing the right tool for driving.

Switching gears to bolts, they’re more like team players, requiring a bit of assistance to display their full potential. Unlike screws, bolts don’t have tapered ends, and they lack the ability to cut into materials.

They depend on pre-existing holes and often require a nut to secure them. The action is more about ‘clamping’ than cutting.

Bolts are the go-to choice when dealing with heavy-duty assembly, where high strength is required. Whether it’s the vehicle assembly line or the construction of a sky-scraping edifice, bolts remain the undisputed king, providing long-term, secure connections. But remember, to get the best out of a bolt, make sure to pair it with a suitable nut of the same diameter and thread count.

Additionally, bolts offer versatility through a variety of types such as carriage bolts, hex bolts, and eye bolts, each offering unique advantages for different applications.

In this exploration, it’s pivotal to remember that in the fastening world, it’s not about which is superior, screws or bolts – it’s about selecting the right fastener for the job.

One must understand their unique traits, their intended use, and the materials they’ll be working with. So, don’t hesitate to dive in, explore, and experiment – that’s the real joy of the fastener odyssey.

Now, go ahead, put those newfound insights to work in your next DIY project or home repair!

Functional Use of Screws

How Screws Steal the Show in Everyday Life

Every one of us has probably used a screw at some point, or at least encountered one. Whether it’s assembling furniture, hanging pictures, or making repairs around the house, screws serve as unsung heroes of stability, leading us into the fascinating world of fasteners.

At first glance, a screw looks deceptively simple. But don’t let its humble appearance fool you. This part-rotational, part-linear device is one of the fundamental mechanisms that power the world around us, often securing and holding together the products and equipment we use daily.

Now, let’s venture into the practical aspects of screw usage – why do screws reign supreme in the fastener universe, and how do they excel in the applications they’re most commonly used for?

- Firstly, screws are a technician’s best friend during assemblies that require precision. When assembling intricate devices, electric appliances, or machinery, screws offer control. How? It’s simple! The helical thread surrounding the screw allows for minute adjustments during installation or removal, ensuring a secure, tight fit. It lets us have some fun while playing with accuracy!

- Screws also have an uncanny ability to adopt and fit in. They easily adapt to the application environment which allows them to be used almost everywhere – be it metal, wood, or plastic. These handy little buddies can even bite into softer materials, requiring no pre-existing holes – a drilled pilot hole or a little pressure, and voila!

- But what about those heavy-duty jobs where strength becomes vital? Worry not, for screws bring in their ‘high-tensile strength.’ This quality allows screws to hold together heavy machinery, home appliances, aircraft parts, and even skyscrapers, making them not only versatile but also all-encompassing in their scope.

- It’s also worth appreciating screws for their integral part in the bonding process. They not only hold A and B together, but they maintain that hold over time, even under the test of natural elements. They can be easily removed and reinserted, making maintenance and repairs practical and effortless.

- Now you might be thinking, ‘What about bolts? Don’t they do almost the same job?’ While that’s true to some extent, screws are self-sufficient. Unlike bolts, they don’t rely on nuts for grip and support. This makes screws more popular in applications where the accessible area is limited.

- To further equip you with knowledge, let’s delve into the ‘righty tighty, lefty loosey’ maxim. This pithy saying is the key to understand a screw’s function. By universally standardizing the tightening and loosening directions, operating screws becomes incredibly straightforward.

Building up the knowledge of screws and making the most of them can be remarkably rewarding, both practically and mentally. The vast world of screws and fasteners is always ready to welcome every curious mind.

Whether you’re undertaking a DIY project or gearing up to fix that wobbly chair, remember, there’s always a screw for the task – you just need the right one. So get your screwdrivers ready, and dive right in.

Functional Use of Bolts

The exclusive strength of bolts in heavy construction

When strength and stability are paramount, bolts truly shine. Their unique construction gives them an edge in heavy building applications.

With unparalleled tensile and shear strength, bolts are the backbone that holds together much of the world’s infrastructure. Their impressive capacity to handle load, especially under tension, makes them ideal for fastening together heavy, load-bearing sections in construction projects.

Moreover, bolts also excel at fastening dissimilar materials together. This versatility is greatly appreciated in varied applications such as joining steel and concrete in bridges, or wooden beams with metal connectors in buildings.

This adaptable nature along with their distinct tensile strength sets bolts apart, making them far superior compared to their counterparts.

Clamping force: Bolts vs. screws

While screws provide high resistance to pull-out and exceed in less-demanding environments, bolts triumph when it comes to the clamping force. This ability to hold two parts tightly together under pressure, also known as preload, has endeared bolts to engineers and builders alike.

The clamping force is derived from the bolt’s tensile strength and the application of appropriate torque. When fastened correctly, a bolt can exert immense pressure between the joined parts, reducing or even eliminating relative motion between them. This helps in maintaining alignment, providing stable and long-lasting construction.

Versatility in joint types

Moving ahead, channels for creativity and versatility in the type of joints are truly unlocked by bolts. Building a pinned joint or a movable joint? Bolts are your buddy!

They’re perfect for joints which require movement, as in machinery, or must bear the pressure of repeated load cycles, like in bridges, lifting devices, and so on.

Furthermore, bolts allow for easy disassembly of joined parts, an aspect which is largely unseen with screws. Applications where periodic inspection or maintenance is required, or where temporary joints are needed, abound with bolts.

Enjoy the power of choices!

When delving into the world of bolts, one would be awestruck by the variety available. From carriage to anchor, flange to eye bolts, each variety carries unique characteristics suitable for specific applications, demonstrating the tailor-made nature of the engineering world.

Take, for example, the U-bolt, specifically designed to hold or clamp around pipes or tubing, providing a firm grip without causing any hindrance to the pipe’s function. Or consider the lag bolt, boasting a coarse thread design making it ideal for use in wood and rough construction projects.

Combine it all with the nuts!

Let’s not forget the unseen, silent partners to our mighty bolts – the nuts. Working seamlessly together, they ensure a secure hold. Variations in nut designs help enhance their utility, permitting them to lock on and resist loosening under vibrations or torque.

In conclusion, adoption of bolts offers immense strength and adaptability. This combined with their easy accessibility and the variety available make them a remarkable tool for hobbyists and professionals alike.

Next time you embark on a heavy-duty job, remember to give bolts a thought! With them in hand, every passion project is possible.

The complexity of structures you can build is virtually limitless. So, take up your bolts and experience the power of crafting firmly bound creations. And remember, there is always room for enhanced mastery and new discoveries in the fabulous world of fasteners!

Choosing Between Screws and Bolts

Navigating the world of fasteners can be a whirlwind of nuts, bolts, and screws.

While they all serve the same purpose—to hold things together—their uses may vary depending on specific circumstances and requirements.

Let’s dive deeper into the great screw versus bolt debate and give an insight on when to use one over the other.

When it comes to small-scale jobs or projects that require a high level of precision, screws have the upper hand.

Screws, being self-tapping, do not require any pre-drilled holes to hold things together.

An excellent example of this can be observed in carpentry work.

Crafting pieces of furniture or cabinets, one cannot forget the powerful role screws play by providing a secure yet reversible connection between pieces of wood.

Furthermore, different kinds of screws such as drywall screws, chipboard screws, or deck screws, serve distinctive roles, thereby broadening the horizon where screws can be deployed.

Bolts, on the other hand, play an essential role when it comes to large scale construction, suspension bridges, and assembling heavy-duty machinery.

Hearty bolts help to maintain the structural integrity when two separated pre-drilled holes need to be aligned.

It is all thanks to their mate, the nut, which locks onto the thread from the other side, providing a seal as hard as rock.

This combination stands to provide an unbeatable tensile strength that does not fail under massive pressure or load.

Bolts like the Carriage bolts, Hex bolts, or U-bolts provide an edge in constructing decks, fixing beams, or even car repair, where strength and stability are the prime concern.

Making a choice between screws and bolts highly depends on your project requirements.

Screws, being versatile and user-friendly, are an ideal choice for household repairs or crafting.

Choosing the perfect screw depending on the material, be it wood, metal, or drywall, can save the day with a minimal hassle installation process.

Bolts, on the other hand, prove their worth when the connection needs to bear heavy loads with enhanced stability.

Whether joining metallic plates, thick wood beams, or securing a piece of machinery, bolts with their variety and strength make them the preferred fastener.

The world of fasteners may appear perplexing, but once the understanding of differences between screws and bolts is clear, it feels no less than a treasure trove.

Having this knowledge helps in making an informed, and the right decision for the task at hand!

Whether it’s a repair job around the house, or constructing a treehouse for the kids, or putting together an engine, the choice boils down to one crucial point: select the right fastener for the right job.

The joy of discovering these aspects of hardware and putting them to the right use is nothing short of a DIY victory!

The avenues where screws and bolts find applicability are unending. Hence, choosing between bolts and screws entails a systematic evaluation of specific parameters related to the task at hand and understanding the strengths and limitations of each.

Recognizing the nature of the task, the type of materials involved, the need for future maintenance, and the load the structure is expected to bear are all crucial considerations.

As enthusiasts or hobbyists in construction and engineering, having a sound understanding of screws and bolts will enable you to select the right fastener for the right job, ensuring durability and reliability of your end products. Remember, a bolt or a screw is more than just a fastener; it’s the thread that holds the structure together.