Star Trek ships had replicators…

Those devices help meet the nutrition needs of Captain Kirk and his crew when they were on long voyages. Markets just weren’t around between markets and something had to be done to keep the crew healthy.

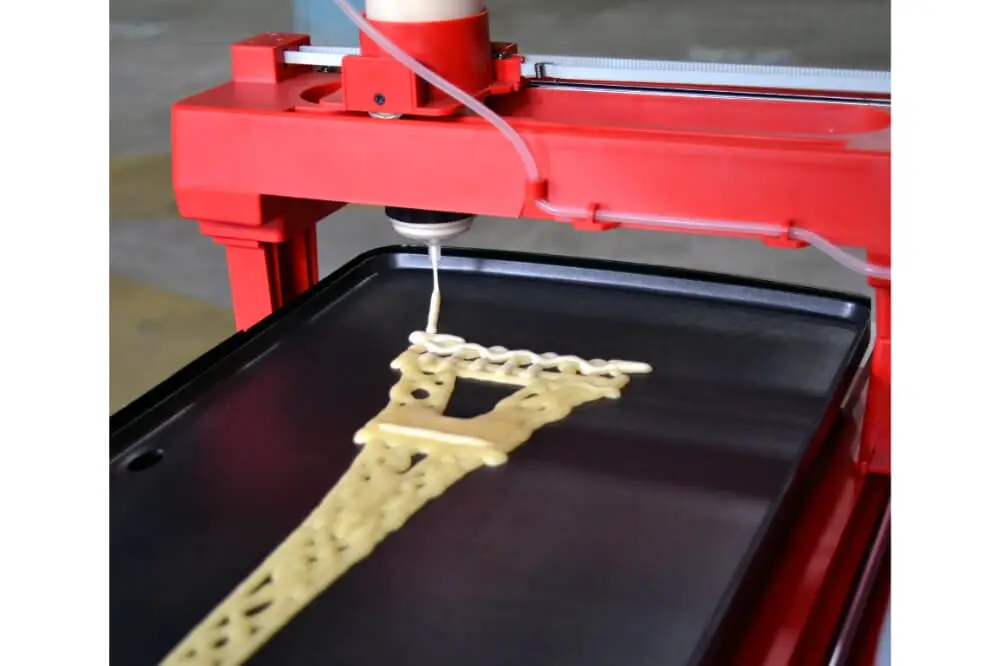

Now 3D printing has expanded the availability of some foods so when you are hungry and do not want to go to the store for supplies, you can simply print out your food. But the process is a little more involved than futuristic food replicators.

To learn more about 3D printing and edible food just continue to read our article. It explores the issue so you can decide for yourself if you want to add these machines to your culinary options.

Can 3D printers print edible food?

Yes some can as not all 3D printers work with plastics. While the answer is a positive and many professionals are adding 3D food printing to their list of food preparation tools, you may not like the price of the printer nor the raw material used in printing food that can be eaten.

The raw material comes in a form of a paste and uses the FDM style of printing, extruding that paste onto a build platform, to create interesting raw dishes. The types of food pastes include:

- Chocolate

- Pancake batter

- Creams

- Pizza dough, cheese & sauce

- Purees

- Mousses

- Dairy products

- And more

The cost of these machines range between $300 to over $5,000 depending on what food you want to print and eat.

Who is the food 3D printer for and does it cook food?

There are limited applications right now for edible food printers but technology is trying to change that as we write. The main groups these printers are for are:

- Restaurants & bakeries seeking to provide a new food experience to their customers

- Food manufacturers- one international company uses food printers to print some of its pasta products

- Home users- when you want to create something different at home

Only one of the many food printers on the market can cook the food it creates. That is the pancake printer from Norway. It places the batter directly onto a hot plate but you still need to do the flipping.

All of the other printers only create the raw portion of the process and many of the food items still need a stove or oven to cook what you have designed. Finding a food printer may be difficult as commercial success has not been much of a success and the product is limited to trade shows and similar marketing outlets.

The pros and cons of food printing

This should be the most important aspect to consider when thinking about buying a food printer for your home or business. The cost is secondary to what is involved in the process.

Pros:

- Personalized meals- whether at home or in the hospital, you get what you want the way you want it

- Preserve minerals and other nutrients- plus you can present certain unappealing raw foods in an attractive way to encourage consumption

- Recipe sharing- is made easy as no one has to write out the ingredients or how much of each ingredient is needed. You just email a digital file to a friend

- Saves time- you just need to set up the printer, press the print and go off to do something else while it prepares your meal

- Enables creativity- you can impress family and friends with your cooking style

- Add a skill- there is training involved so you can add to your list of skills

- Images- some machines can draw images on cups of coffee, etc.

- Special designs- also, some printers can decorate cakes and pastries for you

Cons:

- Cost- the machines and the pastes are not always budget friendly

- Printing time- this can range between 7 and 45 minutes depending on complexity of the food target

- Training- these are not plug and play devices. You have to learn how to use them and that takes time

- Processing time- foods need to be pre cooked or processed to meet the extrusion requirements

- Limited food options- food must be in paste form to work

- No cooking- with one exception you still have to heat up your oven or turn on your stove to finish the meal

- Success is not guaranteed- just like other 3D printing processes something can always happen and your perfect meal is ruined

- Multiple use- some extruders also print non edible food products like clay and silicone, so be careful to clean those tubes well

Why print food?

This is a very reasonable and logical question. Besides being a novelty item, there are practical applications that may make printing food more acceptable.

| Reason | Explanation |

|---|---|

| Control ingredients | Food printers can help you control the amount of ingredients you use as well as the types of ingredients that are on your food. Processed food is not healthy and food printers eliminate that issue |

| Customize your diet | When placed on a strict food diet, it is hard to meet those restrictions through normal means. Food printers remove that burden and help design your food the way your diet requires |

| Cuts down on food waste | The traditional commercial process enables a lot of food waste through handling, shipping, refrigeration and so on. 3D printers cut that waste down and keeps more food available for others |

Also, other 3D printers can print up those food preparation tools you will need to help you create some interesting dishes.

Some final words

Right now 3D food printers are rare. They are also expensive and a lot more development needs to go into these devices to make them more acceptable to the general public.

If you want to eat food that starts out as paste, you may want to spend a few days in the hospital instead. The cost is the same, the food prep seems to be the same and in the hospital you get personal care.

Don’t expect Star Trek capability just yet when you look at 3D food printers.