The 3D printer uses different materials in the manufacturing of different items, from jewelry to toys and aerospace components. There are dozens of popular 3D printer filament spools available in the market. However, plastic still reigns supreme among 3D printer materials.

3D printers are flexible enough such that it allows an individual to determine the texture, shape, and strength of a product. Furthermore, these qualities are often attained with few steps, unlike the traditional means of production.

The market of 3D printing will exceed $1.4 billion before the year 2020; this is according to the SmartTech Markets Publishing study. As the 3D market expands, several industries have come up with new ways of yielding plastic, including using organic ingredients such as corn and soybean oil. In accordance to that, in this article, we shall discuss what material a 3D printer prints with.

Related: 5 Great 3D Printers for the Hobbyist

3D printer printing materials

1. Plastic

As previously stated, plastic is the commonly used 3D printing material. In 3D printing, plastic is expected to be the most environmentally friendly material since it is yield from organic ingredients.

Plastic is the most diverse material for 3D printing household fixtures and toys. Some of the products designed from this technique include vases, desk utensils, and action figures. The products are available in transparent and brightly colored forms, with lime green and red being the most popular colors.

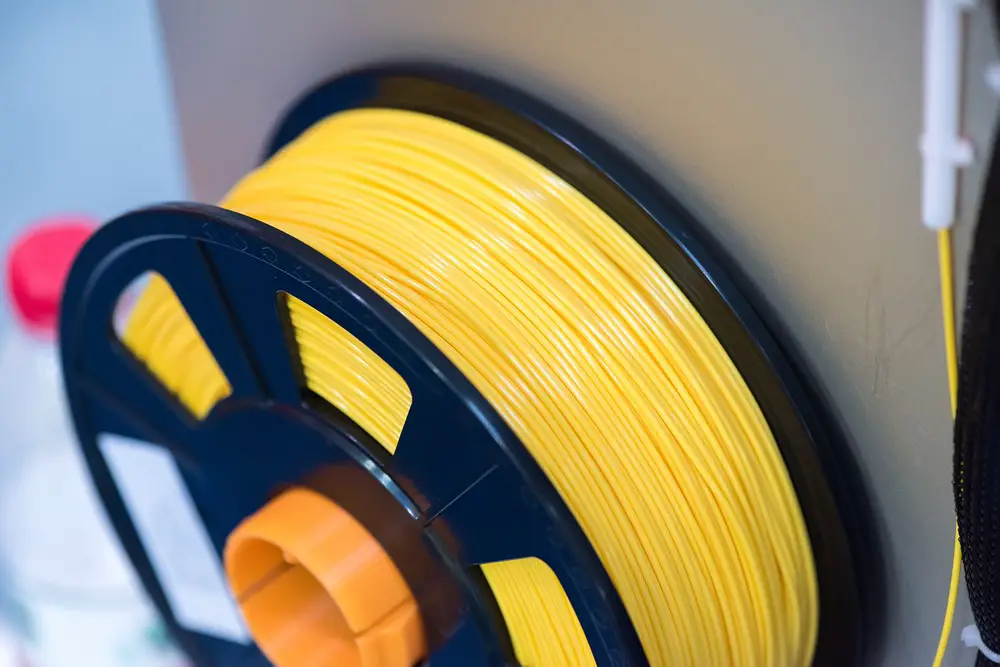

Plastic filaments are available on spools, and they are often in shiny or matte texture. Understanding plastic is relatively easy due to its smoothness, firmness, brightness, and flexibility. Additionally, plastic is affordable and light in weight, making it a perfect 3D printing material.

FDM printers are perfect for making plastic products, whereby thermoplastic filament is melted and molded to shape. The following are the standard plastic material in 3D printing:

- Polylactic acid. Also known as PLA, this one of eco-friendly 3D printer materials available in the market. Manufacturing of PLA is done using organic substances such as corn starch and sugar cane, making it one of the best biodegradable 3D materials. Moreover, PLA is available in hard and soft forms. In years to come, plastic material made from PLA will dominate the 3D printing industry. The harder the PLA material, the stronger it is, making it ideal for creating an array of products.

- Acrylonitrile butadiene styrene. It is also referred to as ABS and is famous for its strength. It is perfect for use in home-based 3D printers. It is consecutively known as LEGO plastic. ABS comes in various colors, which make it ideal for products such as toys and stickers. The material has become popular among craftsmen. Additionally, it is ideal for making vases and jewelry.

- Polyvinyl Alcohol plastic. Also known as PVA, this 3D printing material is often used in low-end home printers. PVA perfect for creating support material with dissolvable variety. However, it is not suitable for 3D models that require robust strength, making it ideal for temporary-use items.

- Polycarbonate. PC is the least famous plastic material. This 3D printer material is used in 3D printers that operate at high temperatures and with specific nozzle designs. PC is ideal for creating low-cost plastic molding trays, among other items.

You should note that 3D plastic products come in various consistencies and shape.

2. Powders

Powdered 3D material has become famous in constructing different products in the market. The powder material is melted and molded into layers until it attains the desired texture, thickness, and pattern. These 3D powder materials are sourced from different materials such as:

- Nylon or Polyamide. This material has excellent strength and flexibility making it ideal for creating high-level detail on any 3D product. When it comes to interlocking parts and joining pieces, polyamide is highly reliable. Furthermore, it is ideal for printing handlers and fasteners as well as toys and other figures.

- Alumide. This is a mixture of gray aluminum and polyamide. Alumide is perfect for creating strong and stable 3D models. The material has a grainy and sandy appearance making it a reliable product for prototypes and industrial models.

Material such as copper, steel, and other metals are easily transported when in powder form. Furthermore, when still in this state, you can easily mold them into your most preferred shapes.

3. Resins

This is one of the most limiting and less used 3D printing materials. Resin flexibility and strength is limited when compared to other 3D printing materials. When exposed to ultraviolet rays, the resin will reach its end state since it consists of a liquid polymer. This 3D material comes in various colors, including black, blue, red, green, white as well as transparent. Resin 3D printing material comes in three different categories:

- Paintable resin. This is often used in printing smooth-surface 3D models. Resins belonging to this category feature an aesthetic appeal. This 3D material is perfect for creating rendered facial details figurines like fairies.

- High-detail resins. When building models requiring intricate details, the high-detail resin works perfectly.

- Transparent resins. This is considered as the most robust resin material in creating 3D models. Due to this, transparent resins are ideal for creating an array of 3D products. It is perfect for creating models that are not only transparent in appearance but also smooth in texture, making it perfect for creating rings and chess pieces, among other products.

4. Metal

After plastic, metal is the second most popular 3D printing material. The process of using metal in 3D printing is referred to as direct metal laser sintering or DMLS. This technique is perfect for creating air-travel equipment. DMLS has not only speeded up the production air-travel equipment but also simply the entire production process.

Numerous types of metal are applicable in the DMLS process. Some of the commonly used metals include:

- Stainless-steel. This is ideal for producing cookware and utensils, among other items that often come into contact with water.

- Bronze. When it comes to creating vases, bronze performs incredibly well.

- Gold. It is perfect for printing earrings, necklaces, rings, and bracelets.

- Nickel. Ideal for coin production.

- Aluminum. Suitable for creating metal objects.

- Titanium. It preferable choice for robust and robust fixtures.

Check Out: Some Great 3D Printer Recommendations for You

Conclusion

When creating any 3D printed model, texture, flexibility, and strength will highly depend on the type of material you are using. You should always consider using 3D materials that best suit your needs.