For both seasoned woodworkers and budding enthusiasts, the integrity of their tools is paramount.

The battle against rust – an all-too-common adversary of metal tools – is a continuous one, with hand saws often falling victim to its relentless grasp.

Understanding the enemy is the first step to victory, and in this case, that means distinguishing between simple surface rust and the more destructive deep corrosion.

Armed with this knowledge, you can choose the most effective arsenal of removal methods. This essay sheds light not only on the traditional elbow-grease approach involving manual scraping but also delves into the alchemy of chemical removers, as well as the surprisingly potent natural remedies found right in your home.

So, whether you’re looking to breathe new life into an old family heirloom or maintain the sharp, gleaming edge of your favorite hand saw, the journey to restoration and preservation begins here.

Identifying Types of Rust

Unlocking the Mysteries of Saw Rust: A Guide to Identification

There’s something incredibly rewarding about rescuing and restoring a hand saw. Over time, many enthusiasts discover their passion for bringing these time-tested tools back to life.

One common challenge faced during restoration is rust – the nemesis of any metal tool. But fear not!

Rust isn’t just an obstacle; it’s a storyteller, revealing insights about your hand saw’s past. Knowing how to identify different types of rust can not only help in the restoration process but also in preserving the saw’s integrity for years to come.

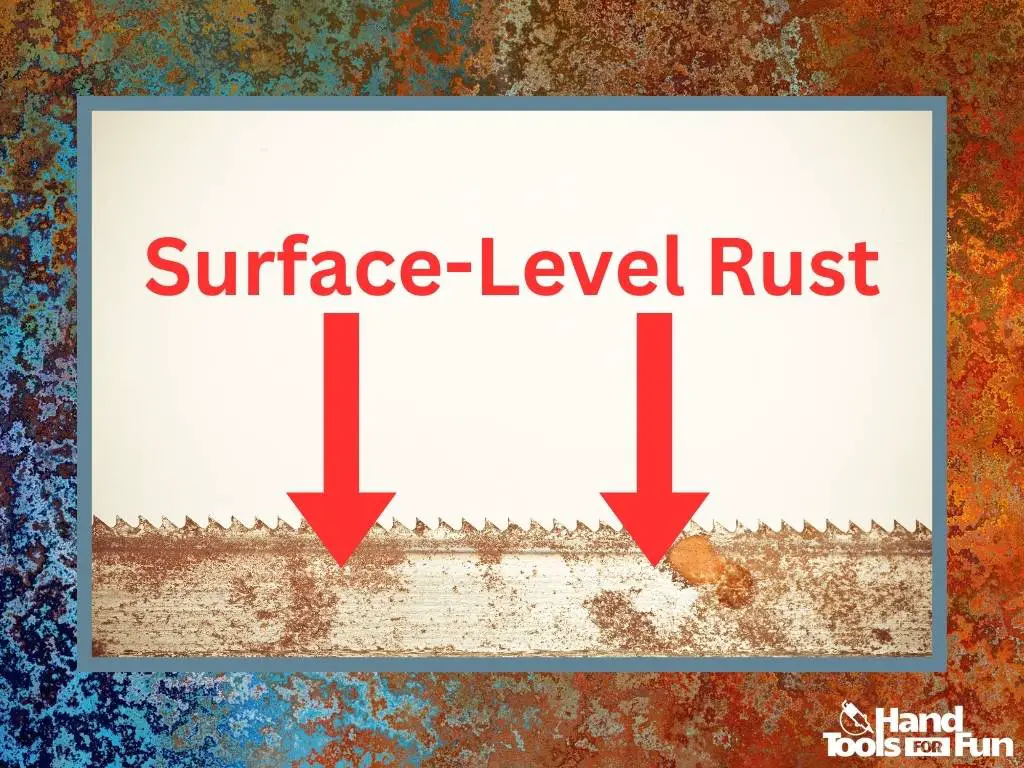

Surface Rust – The Fleeting Foe

The most common type found on hand saws is surface rust. It’s superficial, often showing up after the saw has been exposed to moisture.

Look for a light-orange patina coating parts of the blade. This rust is typically not a cause for alarm and can be dealt with easily.

A simple scrub with fine steel wool or a rust eraser, followed by a wipe-down with a lubricant or rust inhibitor, should clear it right up.

If the saw was stored in relatively dry conditions with brief exposure to moisture, surface rust is likely all you’ll encounter.

Scaling Rust – The Warning Signal

When rust starts to form scales or flakes on the saw blade, it’s an indication that the problem is advancing.

Scaling rust can often look like darker red or brown scabs clinging to the surface. This type of rust has started to pit the metal, and while it’s not the end of the world, it suggests that the saw has seen more significant neglect or exposure to the elements.

Removing scaling rust requires more elbow grease. You might need to use a wire brush or a specialized rust removal tool.

Once the scales are removed, smoothing out the affected area with a finer abrasive will help in preventing further corrosion.

Pitting Rust – The Deep-Set Damage

Now, if you come across deep pitting where the rust has created noticeable cavities or indentations in the metal, you’re dealing with a level of decay that speaks of long-term exposure.

This rust can compromise the structural integrity of the saw blade. Pitting isn’t merely a blemish; it’s destruction.

Restoration at this stage is still possible but requires patience and care. After mechanically removing the rust as much as possible, using a rust converter might be necessary to stabilize the metal and prime it for potential filling and refinishing.

The Unseen Culprit – Internal Rust

Finally, don’t ignore the rust you can’t see. Rust can also form on the internal parts of a saw, like the screws and the nuts.

This hidden rust can cause tool failure if not addressed. Ensuring these parts are free from corrosion and properly lubricated is just as crucial as taking care of the blade.

Identifying the different types of rust on a hand saw is ultimately about protecting and preserving our link to craftsmanship’s past.

By learning to read the rust, you’re not only becoming a better restorer but also ensuring that these beautiful tools can continue crafting stories, and sawdust, for many years to come.

Choosing Rust Removal Methods

Embracing a spotless, rust-free hand saw not only honors a tradition of meticulous tool care, it paves the way for precision and efficiency in all of the saw’s future endeavors.

Understanding the nuances of rust removal allows avid woodworkers and casual enthusiasts alike to breathe new life into what might seem like a tool past its prime.

Let’s dive into a wealth of information on some of the most effective rust removal methods customized for hand saws.

Chemical Rust Removers

When it comes to saving a saw from the menacing grip of rust, chemical rust removers are akin to a knight in shining armor.

These commercial preparations come in various forms, from liquid solutions to gels. Selecting one designed for hand tools can make a huge difference.

Look for ones that are non-corrosive to metal but tough on rust.

Apply the remover as per product instructions, typically using a brush to spread a liberal amount across the affected surface.

After the prescribed time for the chemical to work its magic, typically anywhere from 10 minutes to an hour, the rust can be wiped off.

Always follow up by neutralizing the chemical action (often with water or a recommended neutralizer) and drying the saw thoroughly to prevent any new rust from forming.

Electrolysis for Stubborn Rust

Electrolysis is a slightly more scientific approach but it’s surprisingly accessible for determined hobbyists.

This process involves setting up an electrolytic reaction that specifically targets rust while preserving the underlying metal.

You’ll need a plastic container, a sacrificial piece of steel, some washing soda, and a battery charger.

Fill the container with water, add the washing soda to make an electrolyte solution, then submerge the saw and sacrificial steel, ensuring they don’t touch each other.

Connect the positive lead of the battery charger to the sacrificial metal, and the negative lead to the saw.

Turn on your charger and let the electrons do the work! It might feel like a high school science experiment but once you return to find the rust gone, the thrill of success is unmatched. Don’t forget to neutralize and oil the saw afterward.

Sandpaper and Elbow Grease

Sometimes the old-fashioned way holds up. Fine-grit sandpaper or steel wool dipped in a lubricating agent like WD-40 can be reliable tools in your rust-busting kit.

With persistence and a gentle, circular motion, sanding away rust can be quite effective and also provides a satisfying hands-on approach.

Conversion Coatings

When rust seems like it’s part of the saw’s very soul, conversion may be the answer. A rust converter acts by turning rust (iron oxide) into a more stable compound.

The resulting layer also provides a protective surface and can be a solid primer for painting, though one might argue a hand saw has more character left unpainted.

Brush on the converter following the directions carefully, as proper application is essential for it to work effectively. Don’t rush the drying process; patience here is critical to achieving a solid, protective result.

In the spirit of true craftsmanship, taking care of your hand saws through effective rust removal is not just maintenance—it’s an homage to the timeless skills wielded by woodworkers through the ages.

It doesn’t require fancy, high-tech gadgets, just some thoughtful application of chemistry, physics, and good old-fashioned manual labor.

And might one add, nothing beats the joy of slicing through wood with a blade that’s been given a second lease on life.

A saw well-maintained is a testament to an ethos that values precision and longevity in every stroke, every cut, every project.

Protecting and Preventing Future Rust

Protecting Your Hand Saw from Future Rust Conundrums

A stitch in time saves nine, as the saying goes, and when it comes to keeping hand saws in tip-top shape, preventative measures are worth their weight in gold—or at least the cost of a good saw.

Protecting a saw from rust not only maintains its sharpness and usability but it’s also a nod to a woodworker’s commitment to their craft.

Let’s dig into simple yet effective ways to ensure the edge of a trusty hand saw remains untarnished by the perennial nemesis of iron and steel: rust.

1. Keep It Dry – Always

Moisture is the bane of metal tools. Each time a saw is used, make sure to wipe away any moisture from the surface with a clean, dry cloth.

This goes for humidity, sweat, and condensation too. It’s a small step, but it might just be the strongest shield against corrosion.

2. Store Smart

Where a hand saw calls home when not in action is pivotal. First and foremost, sidestep damp locations.

Opt for a dry environment, perhaps with a dehumidifier if one’s in a region prone to moisture. Consider wall-mounted holders or magnetic strips; they allow air circulation around the entire saw, keeping it dry and off potentially damp surfaces.

3. Say Yes to Oil

A light application of a protective coating like camellia or mineral oil forms a barrier between metal and moisture.

Apply a thin film along the blade after each use. Don’t overdo it—excess oil attracts dust and creates grime over time.

4. Embrace the Wax

For long-term storage, consider a coat of paste wax. This will further seal against moisture and it’s relatively long-lasting compared to oil. Buff the saw blade lightly after applying the wax to avoid any buildup.

5. Rust Inhibitors Are a Plus

Products like vapor corrosion inhibitors (VCIs) are designed to release compounds that actively prevent rust.

These come in various forms including papers, sachets, or even foams that can line toolboxes and cases.

6. Regular Check-Ups

Regular maintenance checks are essential. Even with all these precautions in place, an unexpected spot of rust can occur.

Catching issues early means they can be addressed before they become problems that diminish a saw’s performance or require comprehensive restoration.

7. Silicone Saw Covers Are Handy

Consider slipping on a silicone-treated saw cover when not in use. They often repel moisture and prevent dust buildup.

They’re especially useful if saws are kept in less-than-ideal conditions where humidity might be tricky to control.

8. Opt for Rust-Resistant Blade Coatings

The market offers a variety of saws with specially treated blades to resist rust. If purchasing a new saw is in the cards, look for one with these added features.

9. Routine Cleaning Matters

Don’t wait for rust to show up. Clean the saw blade regularly with simple soap and water to remove any residues that might attract moisture. Dry immediately and thoroughly after.

Caring for a Hand Saw is an Ongoing Relationship

Remember, for those who bring their heart and soul to the workbench, a hand saw isn’t just a tool—it’s a partner in creation.

Prolonging its life through judicious rust prevention is not only a practical approach to tool maintenance, it’s an investment in the continuity of skills and the satisfaction found in every clean cut of wood. Happy sawing, and let those sawdust showers be the only thing settling on your cherished tool.

With your hand saw now liberated from the grips of rust, a final act remains. Protection is the guardian of your hard work, the shield that will defend against the future onslaught of oxidation.

Embracing a meticulous approach to after-care—with a hint of preventive wisdom—will ensure that the brilliance of a well-maintained hand saw endures.

Regular applications of protective oils, adopting proper storage solutions, and committing to a routine of conscientious maintenance transcend mere tasks; they manifest as a craftsman’s creed.

Stand proud in the knowledge that your dedication to the well-being of your tools is the hallmark of true craftsmanship—a tradition that honors the past while forging ahead towards a future of flawless cuts and enduring hand saws.