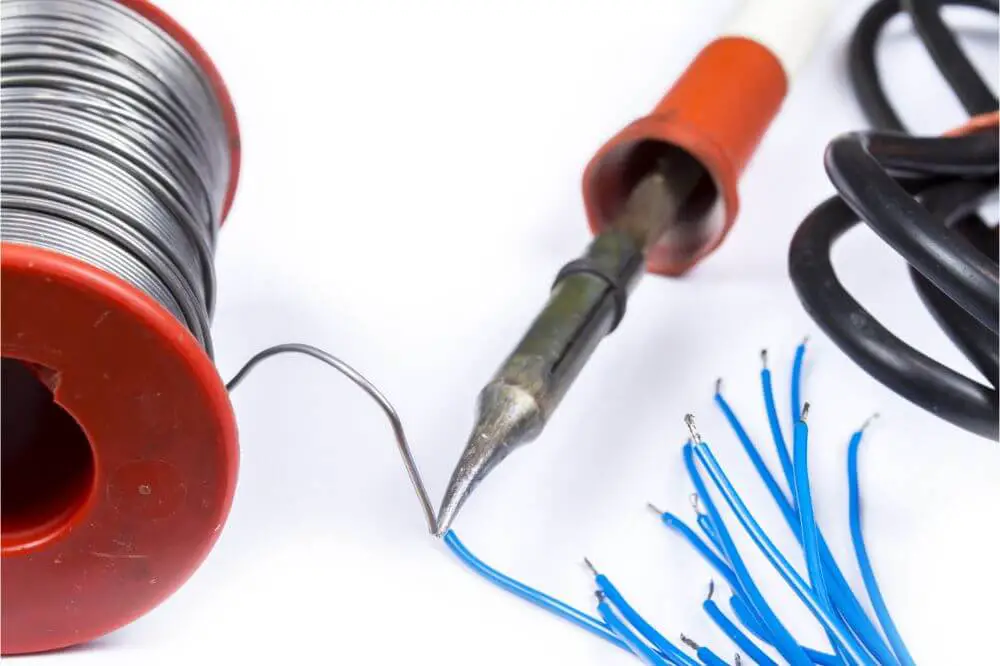

Soldering is not the only answer…

When you have loose wires or need to make a connection, you do not have to use a soldering iron to get the job done. If you are comfortable with working around wires you can use different methods to attach those wires.

The key, of course, is to make sure you unplug the device you are working on before you start fiddling with the wires. To find out about those different methods, just continue to read our article.

It gives you the information and directions to make sure you do the task correctly. Take a few moments and get up to speed on connecting wires.

Why join those loose wires

The simple and obvious reason is that you have to maintain the flow of electricity so all your electrical appliances, toys, and electronics work properly. This has to be done whether the connection is loose or the wire you are using is too short and you need to extend the length.

Once you got the wire connected to the right place, be careful of reverse polarity, you should be able to enjoy those electronic items once again.

5 different methods of joining wires

| Number | Method | Explanation |

|---|---|---|

| #1. | Wire connectors | This is one of the easier methods to use. All you need to do is put both ends of the wire inside the connector and twist till tight. |

| #2. | Electrical tape | This method is old school but still used frequently today. Just cut the coat off the end of the wires and wrap the two ends together. Then wrap the electrical tape around that joint. |

| #3. | Alligator clip | This method could be for temporary situations while you test the connection. Put the two ends of the wire close together then clamp the metal clip over both ends creating a complete circuit |

| #4. | Hot glue | You will need a glue gun and warm up the glue first. Then when you have removed the coat off the ends of the wire, twist the two ends together and apply the glue. The connection is strong plus you get built-in insulation protecting the connection. |

| #5. | Crimp method | Similar to the wire connector. You twist the wires together very tightly and slip them into what is called the crimp. Then you take the wire cutters and put the connection in the crimping part and squeeze the handle. You need to squeeze hard to keep the connection from coming apart. |

| #6. | Screws | Usually reserved for outlets etc., wrap the wire around the screw and tighten. |

The tips to connecting wires together

There is some skill involved in putting two wires together when you are not using a screw and a screwdriver to tighten that screw over loose wires. Here are a few tips to help you do it right.

#1. Stripping the wire– this can be a difficult task for some people as they always press too hard and repeatedly cut the wires and not the insulating coat. Use wire strippers and apply the right pressure to take just the coat off only.

#2. Just enough is needed– another major mistake many people make is taking too much of the coating off. You are left with a lot of exposed wire which you need to trim before you can use it. Bare enough wire so that the methods listed above can safely cover and connect the exposed wire ends. Rarely do you need to go beyond 1 inch.

#3. Electrical tape– not only can this tape cover wire and keep a connection, but it can also provide added security and insulate the wires from the elements. Between 3 to 5 wraps should do the trick. You can use electrical tape around the hot glue, the crimp, and the wire connector methods as added protection.

#4. Alligator option– only use this method when you have temporary connections to make. It is the easiest one to have short out on you. Go to the other methods when you need a permanent connection that is well insulated.

#5. Connecting circuit board circuits– the best method to use for this task is the hot glue. When you can’t solder, the glue works on the same principle and makes sure your connections are not interfered with and not bulky

#6. Double-check your work– nothing is more frustrating than to make the connection, apply the right method only to see your electronics short out on you when you turn it on. Double-check your work as even one little loose copper strand of wire can touch something and short the circuit. Make sure you have all strands of wire in the connectors and insulated from other parts of the electronic equipment.

Wiring mistakes to avoid

When you are working with wiring, it is easy to make mistakes. Some people like to cut corners and save a buck or two or you just made an error in judgment. In any case here are some mistakes to avoid when working with or without solder:

- Excluding the junction box- this protects against shorts, the elements and helps prevent fires

- Cutting the wire too short- measure twice and cut once applies here

- Exposing wire cable- when you run wires from point A to B you should have them protected the whole way. Loose wires can easily be damaged

- Forget to tighten the wires- usually, this happens when screws are involved and the screws are not tightened enough

- Too many wires in one spot- this is an accident waiting to happen

- Misconnecting wires- this happens a lot. Some people accidentally place hot wires on neutral or reverse the polarity so make sure you connect them right.

Some final words

You don’t need solder to make a great electrical connection. It helps especially with computer circuitry. But with the majority of methods listed above, you can do fine without using solder.

It just takes a little confidence and a little know-how and your wire to wire connections will be safe as well as sound.