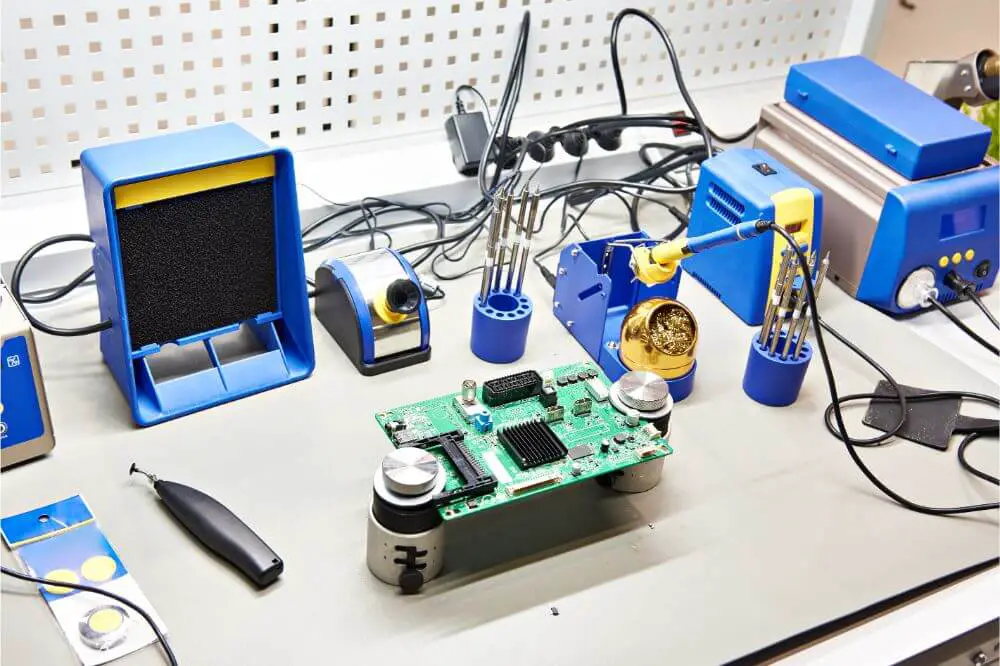

In using a soldering iron…

You have a great tool to apply or remove solder. But what if you do not have a soldering iron or it is broken, or you lent it to a friend? Then desoldering different wires becomes a creative task and you will need to use different items lying around your home.

To learn how to desolder different items without using a soldering iron, just continue to read our article. It has the information you want so you do not have to go out and make a special trip to buy a soldering iron.

How to desolder without using a soldering iron

Many tools have many uses other than their primary purpose. Sometimes it just takes a little common sense to see those alternative uses.

| # | Tool | Description |

|---|---|---|

| 1. | Flat head screwdriver | Its head is shaped like a chisel soldering iron bit. Just heat it up with a propane torch and place the heated end against the solder you want to remove. Make the end red hot and use an old screwdriver |

| 2. | Desoldering braid | This tool is a braided set of copper wire that soaks up the solder after you heat it up. Some of these braids come with the flux already on them but if not add your own |

| 3. | Desoldering pump | This device may need the assistance of a soldering item as the solder needs to be heated and melted before you use the pump to suck up the melted solder |

| 4. | Heat gun | Instead of using a soldering iron, this tool will heat up the solder enough for either the pump or the braid to absorb the melted solder. |

| 5. | Hot air stationSlightly more expensive than a heat gun, this does the same job but provides you with a more professional removal. The hot air station is designed specifically to remove solder without using a soldering iron | |

| 6. | Compressed air | Heat the solder with the heat gun or screwdriver and then use the compressed air to blow the solder away from its originating point. You will need to wear safety goggles and gloves as you will have hot solder flying everywhere |

| 7. | Compressed air 2 | Turn the compressed air can upside down and use the cold air to create brittle solder. Then take a pair of pliers and pull the solder and components off their spot |

| 8. | Small chisel | This is like the hot screwdriver trick. Heat it up if you have an old chisel but not an old screwdriver to use. Then place the chisel against the solder and melt it |

Pros and cons of non soldering iron removal

Everything has positive and negative factors to it. Even when you try removing solder without a soldering iron. There are pros and cons to each technique listed above and this list will help you choose the right one for you and your project

| Technique | Pros | Cons |

| Screwdriver | Efficient and has a chisel bit like blade | Can get to hot and burn you, the components or wiring |

| Desoldering braid | Cheap, effective, easy to use, and comes in a variety of sizes | Each section cannot be reused. You have to buy a new one every time you use up the current one |

| Desoldering pump | Comes in many different formats including an electronically heated version | Large tips make it hard to get into small spaces |

| Heat gun | Simple and easy to use, may not harm components | Heats up fast and can harm your fingers or the board quickly |

| Hot air station | Professional results | Can be expensive |

| Compressed air | It is fun, quick, and protects the components | Spreads solder everywhere |

| Compressed air 2 | Does not get hot or burn you or your components | May permanently damage components |

| Hot chisel | Convenient, tough, and sharp | May burn components and your fingers |

This list is only the start and applies to the through hole components. You may already have developed your own techniques or know someone who has. There are a lot of methods you can use to remove solder without a soldering iron.

Why you would desolder

Everyone has their reasons for why they need to do this task. Here are a few of those reasons:

- They are retrieving usable parts to use in other systems

- They need to fix a broken circuit and get it working again

- They need to replace a broken component

- They need to repair solder joints

9 Safety tips to follow when desoldering

When working with solder and heat you should practice good safety habits in order to avoid injury. The following list will provide you with a good guide:

- Use flux to help the melted solder flow and avoid oxidation

- Do not heat the components for too long, too much and too high a heat will damage the components.

- Add lead solder to lead free solder to lower the melting point and makes the task easier

- Work in a well ventilated area as the fumes of desoldering is dangerous

- Protect your work area with a silicone soldering or heat resistant mat will do the trick

- Protect your hands from any heated item or device you are using. Keep them away from hot areas.

- Larger components need more heat to remove the solder, be careful when upping the temperature on your tool

- If the component has lots of layers of copper then more heat will be needed making risky for fingers and components

- If you are using a hot air station or heat gun, keep the nozzle at the appropriate distance from the components but close enough to melt the solder. This is a trial and error guide.

Some final words

Desoldering is a necessary task when you have a broken circuit or part. Use a soldering iron whenever possible but if you can’t then any one of the listed tools above will do the job for you.

Also, take the right safety steps to protect your fingers and your eyesight. Wear the right protective gear that won’t interfere with your work.