Wondering how someone designs the tag of your furry friend with engraving? How about your ever-favorite mugs? These and other precious gems are ideal for souvenirs.

Want

to know how to perfectly engrave highly personalized and delicate

patterns on a particular item that is made of stainless steel? You’re in

luck! We will discuss the process in this article, so make sure to keep

reading!

Stainless steel is one of the most popular and attractive material options for daily uses – from markets to industries. Hence, Do-It-Yourself buffs and businesses start engraving stainless steel products and selling them or surprising their friends or loved ones with delicately designed engraved souvenirs. Engraving stainless steel offers numerous advantages that even beginners would love starting the procedure now.

The Engraving Process

Okay, we feel your excitement for engraving stainless steel for the first time, so let’s start with this guide at hand.

- Clean the stainless steel. Use a dry cloth to get rid of moisture and a damp cloth to clean the material’s surface. Scrub using a soapy water if it is still grimy. Allow drying.

- Design the metal. Print or draw out a design you like or need that has well-spaced, simple lines. This is especially perfect if you’re only working on a small item. If you want to engrave letters, draw them between two parallel, straight lines to make them even. Use a ruler.

- This step is only important if you have to transfer the design on the stainless steel. If not, proceed on the next step. Add a shellac or varnish to the metal’s engraved area. With a soft lead pencil, draw your preferred design on the polyester film. Cover it with a scotch tape, rub thoroughly using a burnisher or your own fingernail, and then lift up the tape gently. The design must be now on the tape. Stick the tape over the area you have varnished. Rub it using a burnisher or your fingernail and remove.

- Prevent the stainless steel from slipping with a vise or a handheld clamp. Though, be careful when using the clamp because it increases the possibility of scrapes or cuts.

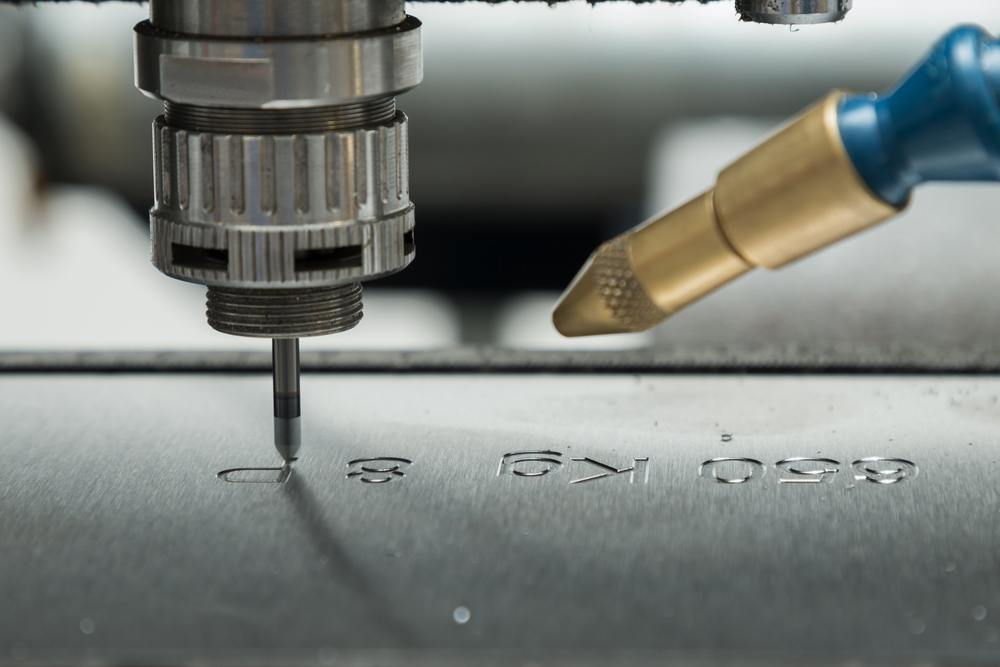

- Use a tool you choose to turn your drawing into a real engraving. Keep the tool’s end at a similar angle all through the engraving. Work a straight line in every direction until you see a deep cut. Use it to move on to the remaining lines.

Can your laser engrave stainless steel?

Absolutely, YES. In fact, it is a popular engraving technique for various materials, including stainless steel.

When we say laser engraving, it is a method in which the laser beam will physically extract the material surface to expose its cavity. This eventuallyshows an image that is perceptible both to the touch and eye. Laser engraving usually comes in three types – laser ablation, etching, and deep laser engraving.

How to Laser Engrave Stainless Steel

Engraving is usually done by reducing the marking speed and increasing the laser power. For deeper engraving, the best technique is to get rid of small particles of material through multiple engraving passes. While for accomplishing deep engraving and still keeping a cleaner edge and trough, several lasers passes with various angles of fills at higher speeds may be better.

Adjust the laser power, fill density, fill angle, number of fill passes, and galvanometer speed for optimal results. Specific setting numbers merely depend on the particular laser, system software, and focusing lens. For instance, a fifty-watt fiber laser with around 255 mm focal length or lower can be able to produce awesome stainless engraving results.

On the contrary, a twenty-watt fiber laser with approximately 330 mm focal length or longer is not well suitable for deeper stainless engraving. Take precautions and be aware of the risks, though. Ensure to use a fume hood, a laser engraver with a covered workspace, and a protective mask so you won’t inhale the harmful particles, like nickel and chromium.

Choose the Right Engraving Tools

There are tons of engraving tools and accessories available in the market. The diamond wheel points are among the most important tools you should add in your toolkit to engrave those accurate details. These are specifically designed for fine-detail engaging jobs. It is also ideal for engraving glass and other harder materials since the bits are coated in diamond particles.

On the other hand, the collet spindle could be your best cutting tool. Using it, you have more choices compared to conventional single fluted engraving tool. You might want to consider getting a two- to four-flute tool intended for machining metals.

Otherwise, a quarter round is a good option in case you want to stick with engraving bits. It provides a good clearance for the chip removal all through the cutting process. Plus, the lowered surface area helps in reducing the buildup of heat. Half-round cutters might also be the item you want to add in your tools. When it comes to choosing a cutter material, there are two options you have: carbide and high-speed steel. The latter is not specifically recommended unless you have a cutter grinder to use for sharpening. Get your chosen tool sharpened particularly for stainless steel.

Take the Proper Safety Measures

Even when engraving, do not overlook what safety gears could offer to make your entire work a lot more convenient, easier, and safer. Wear leather gloves to protect your hands. They are resistant to wear and tear as well as prevent scrapes and cuts. Of course, don’t forget the dust mask and goggles as part of your engraving essentials. They make sure you won’t breathe in metal shards and prevent the tiny glass from getting anywhere close to your eyes.

Whether it is engraving a nameplate for home, park signage, or a simple flatware, stainless steel engraving is such an excellent method to convert plain objects into precious keepsakes. Now, you have a complete understanding of how to create and design images, handy symbols, or words on huge or small stainless-steel objects.

Ready, set, engrave!