Soldering irons are crucial tools that are a must-have by professionals and hobbyists when doing soldering tasks. Without this tool, the melting of solder around electrical appliances wouldn’t be possible. You can get the soldering iron in a few variations, including a soldering gun or a soldering pen.

With that said, do you know you can also design your electric soldering iron at the comfort of your home? If you’re skeptical of whether this is possible, this article is meant for you. Here is a detailed outline of the steps to follow when making a soldering iron at your home’s comfort.

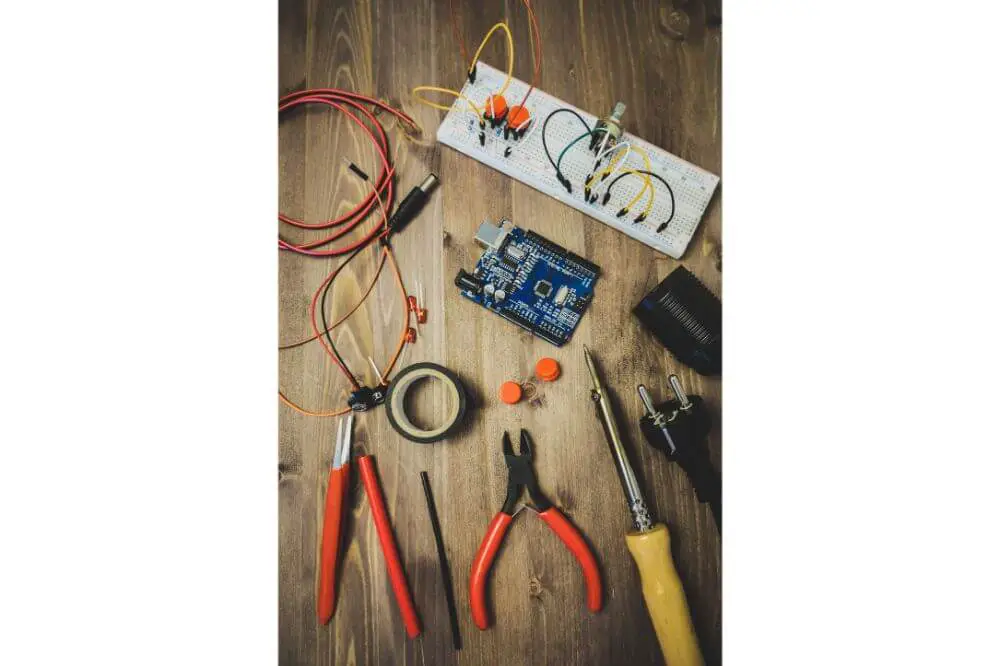

Materials Needed When Making An Electric Soldering Iron

Before we take you through the steps of making a homemade soldering iron, it’s first essential to know the needed tools. With these tools in place, you can be sure you’re your goal of making a soldering iron at home will be a success. These essential tools include:

- Pen

- Pencil

- Pliers

- Electrical wires

- File or sandpaper

- Utility knife

- Adhesive tape

- Welding goggles

- Heat resistant adhesive tape

- A flexible piece of metal

- Power supply unit (PSU)

- Pair of scissors

- A soldering flux

- Handle

- Screw

- Copper tip

These are the essential items you must have before you start making your soldering iron. Once you’ve got all of them, you can proceed to start making your soldering iron.

Steps of Making The Soldering Iron

When making a homemade soldering iron, you need to remain extremely cautious throughout this process to avoid any possible injury. As you do this, you also must follow the steps accordingly; otherwise this exercise will be in vain. The steps to follow when making your soldering iron include:

- Sharpen the pencil carefully using the kitchen knife. As you do this, be very cautious to prevent the pencil’s graphite from breaking into pieces. Thus, you should ideally sharpen your pencil as you would have when planning to use it.

- After getting the graphite, you should now think of ways of getting hold of it. A great way of doing this is by using either a plate or a thick wire. When searching for these materials, the most important properties to look for is the presence of an end which can be shielded in electrical wire and bendability.

- Hold the tip using a pen since this acts as an insulator. While doing this, you need to be careful, taking into account certain plastics produce harmful gases when they burn.

- Please take out the pen and cartridge’s internal parts such as the spring and cartridge, which allows it to grip the tip and remove the cap. Depending on the kind of pen you have, proceed to either break, cut or disassemble it to be useful.

- It’s important to consider the type of pen and graphite to establish how well these two can fit together. Using a file, you can choose to cut the pen into the desired shape. Once you’re done, pass the electrical wire through the pen and cover it using a metal piece to prevent a possible disconnection.

- For you to get hold of the tip holder, you’ll need to insert a piece of metal inside the pen. It’s recommended you cover the tip using tape when using a heat resistant tape. If you can’t find a heat resistant tape, don’t worry since the tip can still be operational.

- After doing all this, the task remaining is wiring the tip to the PSU. Before you do this, it’s crucial first to have a great understanding of where the wires are located, especially the colored ones. Subsequently, you’ll have to learn about GND since it’s crucial to connect with these wires.

- The next step you should take is connecting the connected wire to the pen to one of the chosen rails. Once you’re through, connect to the ground the other wire. If you want them to remain firmly connected, you’ll have to make use of a normal tape to cover them together.

- Once you do this, you’ll be ready to do test your soldering iron. You should do this by starting to heat the tip. As you do this, make sure to touch the graphite using a free wire connected to the ground.

Precautions To Observe After Making Your Soldering Iron

You’ll need to remain very cautious when making a homemade soldering iron. Here is an outline of the safety tips you must observe to guarantee your overall wellbeing:

- Ensure to make your homemade soldering iron in a perfectly ventilated room.

- Make sure to wash your hands after making the soldering iron due to contact made with toxic materials.

- Never place your homemade soldering iron on the bench to prevent possible damages.

- Be careful when using the soldering iron to avoid starting a fire or burning yourself since it heats to about 400ºC.

- Always store the soldering iron in a safe place anytime you aren’t using it.

- Try not to inhale the air as you work with the soldering iron to prevent any possible adverse side effects.

- Never touch the tip of your soldering iron when it’s connected to power since it may shock or burn you.

By observing these safety tips, you’ll be able to guarantee your wellbeing while making the soldering iron at home and when using it. Subsequently, you’ll be able to carry out whichever tasks are at hand effectively.

Conclusion

The soldering iron is a useful and practical tool that allows you to carry out your soldering tasks with ease. You can get this tool from your local store, but making one is also a suitable option if you’re on a tight budget. The problem is not knowing where to start, and if this is something that many individuals struggle to identify.

If this is something you also have been experiencing, reading through this detailed article has given you insights on invaluable steps to follow when making a homemade soldiering iron. With this in mind, you’re now better placed to take the steps needed to create one for personal use without lots of strain.