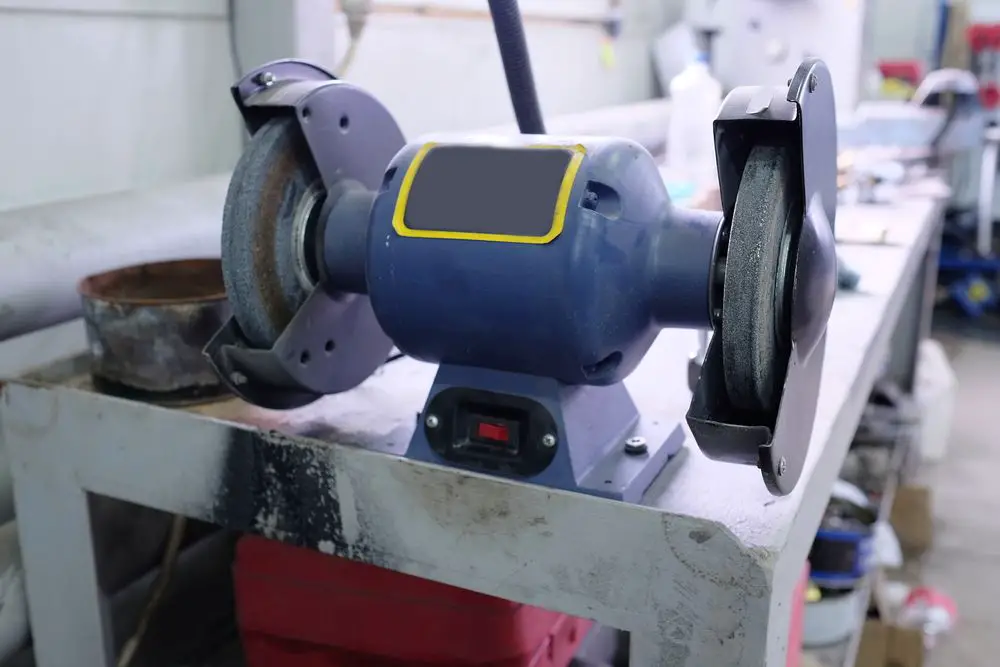

Are you an enthusiast of making the homemade tool? Do you know you can convert your bench grinder into a sander? Well, you may ask how? If you would like to know how you can do this at home or in your workshop, you need to read this article. This article provides you with a a-step-by-step procedure on how you can turn your bench grinder into a belt sander.

A belt sander is a machine used for finishing as well as shaping wood materials and among other elements, that need sanding. It has an electric motor which runs a pair of drums. It is on this pair of drums that you do the mounting of a continuous loop of sandpaper.

How are Belt Sanders Used?

A belt sander is mainly handheld and works by being moved to and fro on the material on the piece of timber. Due to the aggressive action they have on wood, their primary use is in the initial stages of the sanding activity. They also work best where one needs to remove rough materials from the woods rapidly.

Sometimes they are also used to remove finishes or paints form timber. Fitted with a fine-grit of sandpaper, a belt sander can be used to obtain an absolutely smooth and flatten the surface.

How to Turn a Bench Grinder into a Belt Sander

To turn your bench grinder into a belt sander, there are some few materials you need to have. These materials are: a piece of angle iron or 3mm steel plate, internal whole bearings of 32mm x 12mm x12mm for the front wheel, flat bar measuring 10mm x 30mm, a pipe of 35mm x 15mm (the thickness of its wall should be 1.5mm so that it provides an internal diameter of 32mm) and finally you will need to have some bolts and nuts.

Step 1: make the front wheel

- The easy way of making a front wheel is by using bearings without casing. In a situation where your bearings are not of the right size, such that if you use two, they will be too narrow and when you use three, they become too wide, it is advisable to make a casing for them by just using a pipe.

- Cut two 31mm long pieces from the pipe you are having (the one you use it for the front wheel and the other for making the pulley)

- File the cut ends to make them clean using a file

- Harmer dimples around the bearings to lock them inside the pipe, by hitting dimples on the surface, they make dimples on the backside as well, these dimples, in this way can keep the bearings in a firm position.

- Start by making shallow dimples, then hit them deeper slowly until the bearings are firmly in place.

- Leave some distance of around 15mm between your bearings and an interval of 3mm to the edge of the pipe.

- In circumstances where you only need to fasten the outer bearing, ensure that the internal ones are leaning against the washer that leans against the arm.

- Fasten the front wheel to the arm using M12 bolt and place the washer on both sides of the bearings,

Step 2: making a pulley

- Use a belt of 30mm width

- From the pipe, you already have 35mm by 1.5mm wall thickness, cut a piece of 31mm long.

- Mark the cut line and cut next to the marked cut line for easy and more accurate cutting.

- Place the pipe on the top of the grinder and hold it into position using nuts and original support plate from the grinder itself.

- The angle grinder used in cutting the pipe should be 1mm thick cut off wheel, which cuts faster and more accurately than the thicker ones.

- For accuracy purpose and to have an easy cutting mark

Step 3: making the arm

- The arm is used to replace the workpiece rest that is in the grinder. Mount the arm to the same place where the grinder rest was.

- If the rest slot was small, shape the arm so that it fits in that slot

- Then round the edge of the arm that goes against the slot to fit firmly in the slot and then cut it into the right size.

- Mark the mounting holes, and before drilling them, make sure the arm can move into the slot.

- After making the holes both on the arm and the wheel, mount the arm using the right size bolt according to the size of the hole you make.

Step 4: making the backing plate

- This plate is made quickly using angle iron.

- Using an angle grinder, cut the iron into the required size, and bend it to 90 degree

- Then make drills, 2 to 5 holes, and place the holes systematically to the back plat.

- Use the belt as a guide to mark the position of the arm on where you will mount the tie the plate.

- On the arm drill 4.2mm holes and thread with M5 tap.

Step 5: assembling

- Mount the arm to the grinder and do not tighten the bolts firmly at this stage.

- Fix the front wheel. Ensure you leave an appropriate distance between the wheel and the arm. In case you would like to adjust this distance, a suitable washer will help you do it.

- Install the belt and then tighten the pulley, by using right size nuts and original support plate of the grinders

- Using an appropriate tool improves the tension of the belt by pushing it from the head of the first mounting bolt as you tighten the second one. Once you tighten the second bolt appropriately, go back to stretch the first one.

- Ensure that the arm is on the right line with the grinder

- Make sure the belt runs straight. If you find it is not straight, you can straighten it by bending the arm on to the right until the belt runs straight.

It is also possible to use the backing plate with a tensioner. In this case, you need to place the tensioner on the opposite side of the backing place, so that it can loosen the belt with ease. Otherwise, you can mount the tensioner both ways, either on the top or downside of the arm.