If you plan on doing some soldering, there are a few things to be familiar with. One thing is soldering flux. In soldering, flux is a material that helps with both the soldering and de-soldering processes.

It can remove oxide films that form on the surfaces of metals soldered together. It also helps increase the wetting capabilities of the solder, which enables it to flow uniformly over various surfaces.

However, although it has many benefits, it must be appropriately used. If you don’t know how to use soft solder flux, you will have problems.

In addition, you need the right kind of solder flux. Let’s go through a tutorial on how to use solder flux.

How to Use Solder Flux: A Tutorial

We want to provide an in-depth tutorial on using solder flux, starting with choosing the right type.

Choosing the Right Kind of Flux and Solder

The first thing is to choose the right kind of flux for soldering.

Electrical Wiring and Electronics

When working with somewhat delicate electrical wiring, you usually want rosin-based flux because it is not very corrosive and, therefore, ideal for electronics with thin and fragile wires. In addition, this is an excellent flux for removing oxidization.

On that note, when you are soldering electronics, go for leaded solder. Leaded solder melts at a very low temperature and is ideal for protecting delicate wiring.

Pipes

However, if you are working on pipes, use something more corrosive, such as acid flux which can remove large amounts of oxidization. This type of flux results in a much stronger seal, higher durability, and waterproofing.

Moreover, if you are working on pipes, choose silver solder. Silver has a higher melting point than lead and therefore works much better for large pipes

Preparation

Now that you know the correct type of flux for specific jobs let’s start our project.

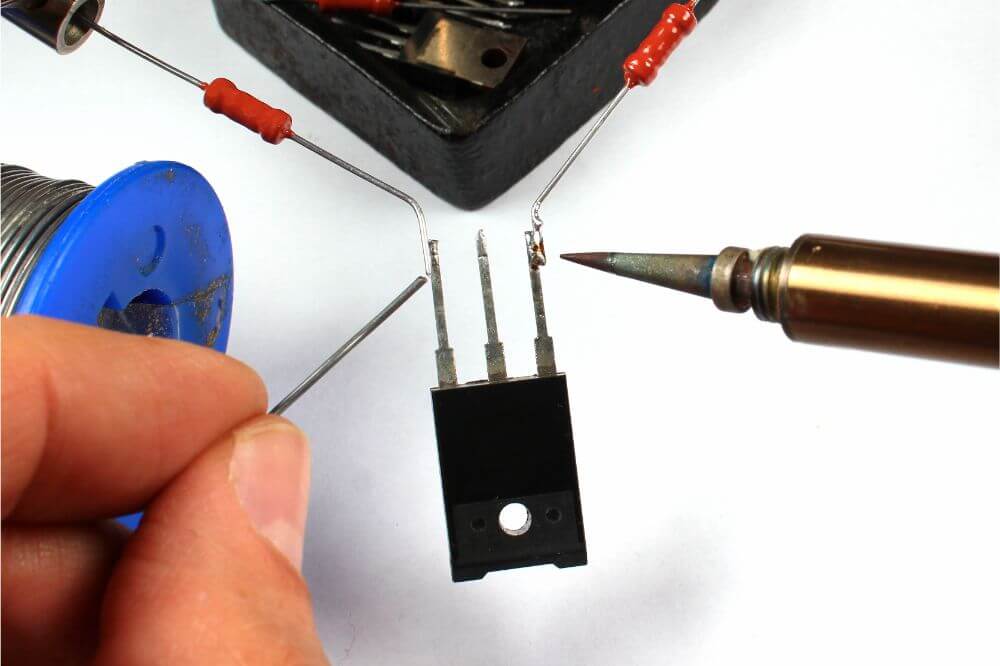

First, turn your soldering iron on and clean it. This is important if you are working with electronics.

Plug the soldering iron in or turn it on, and once it is hot, use a wet sponge to clean the tip. You also want to do some tinning, which means that once it is hot, put a bit of solder on the tip and then wipe away the excess solder with a damp sponge. This will help prevent oxidization while you work.

On a side note, if you are soldering pipes, you might want to go for a blowtorch. Some people say that soldering irons take too long to get up to a temperature ideal for soldering pipes; in this case, a blowtorch may be ideal.

Soldering Wires with Flux

Now that we have completed the preparation stages, we want to cover two main tasks you might want to do. First, let’s talk about how to solder wires with solder and flux.

Twist the Wires Together

The first thing to do is overlap the two wires that you want soldering together. Make a small cross symbol with them both and start twisting them together. Keep wrapping the wires around each other until both ends are pushed down into the other wire. Make sure that there are no pointed ends.

Use Your Flux

With the wires twisted together, use your fingers or a small brush to put some soldering flux onto the wires. Generously spread the flux over the entire area you will be soldering. Make sure to fully cover the wires. Before you start soldering, wipe it off your fingers.

Melt the Flux

With your hot soldering iron, touch the tip to one side of the wires to melt the flux. You should see the flux melting quickly. It should turn into a liquid that will run into the wiring. Keep holding the soldering iron onto the wires just until the soldering starts to bubble.

Start Soldering

Now, use your soldering iron and your solder of choice to connect the wires together. Because you held the soldering iron onto the wires to melt the flux, they should be hot enough so that when you touch the solder to them, it should immediately melt. Ensure that all wires are 100% covered before you stop applying heat.

Let It Cool

Once the wires have been coated in solder, take the iron away and let everything cool. The solder should quickly harden and solidify. If everything has been done correctly, you should see no exposed wiring. You can then cover your wiring with some heat shrink tubing if you want.

Soldering Pipes with Flux

Let’s now go through how to solder pipes using flux.

Clean the Pipes

Use steel wool or sandpaper to clean the pipes as much as possible. You don’t want any dirt or debris on the pipes when you go to solder them. This is necessary to achieve a solid connection.

Apply the Flux

Next, use something like a paintbrush to cover the ends of the pipes in a very thin layer of flux. Ensure there are no lumps or big chunks of flux present. Both acid flux and tinning flux are recommended for this.

Connect the Pipes

With the soldering flux applied, you will now connect the pipes. Push the two ends of the pipes or fittings together until securely connected.

Use a clean paintbrush or a rag to wipe away any excess flux that comes from in between the joints. Working on large pieces can be difficult, so focus on smaller sections.

Heat the Female Connector or Fitting

Using either a soldering iron or a blowtorch, heat either the fitting or the female connector, as this will make it expand. Always heat the larger sections of pipes before the smaller ones. Hold the heat to the pipe until the flux melts completely.

Apply the Solder

Once the flux has melted, press the solder onto the opposite end of the pipe and apply it once the flux starts to bubble.

The pipe at this point should be more than hot enough for the solder to completely melt as soon as you touch it to the pipe. Once this starts to melt, remove the heat and quickly work the solder around the perimeter of the pipe.

Let it Harden + Examine Your Work

Next, let the pipes and the soldering cool down a little. Once everything is cool enough to touch, examine your work to ensure that everything has been done correctly. If you see any areas you have missed, repeat the above steps to complete your job correctly.

Conclusion

Soldering flux is not overly difficult to use, but it does need to be used properly. You should now know how to use it to solder both wires and pipes.