Patience is a virtue…

And you are probably tired of hearing those words whenever you want to speed up a process or get to your destination quicker. Those will be the same words you will hear when you try to speed up your 3D printer.

Unfortunately, speeding those devices up is best left to technological upgrades when they occur. Right now the printing capacity is set and there seems to be no changing that speed at the moment.

To learn why 3D printers go slow just continue to read our article. It gives you the information so you know how long to wait when printing.

Why do 3D printers take so long to print?

In today’s fast paced world, if you can’t do a task now, the customer moves on to the next place that will. But 3D printers have not reached that level of performance yet and there are good reasons why that is so.

One main reason is due to the speed settings on your printer. They are grouped according to the following ranges, and these are averages and their speed is measured in millimeters per second:

- 1st group– 40 to 50 mm per second

- 2nd group– 80 to 100 mm per second

- 3rd group 150+ mm per second

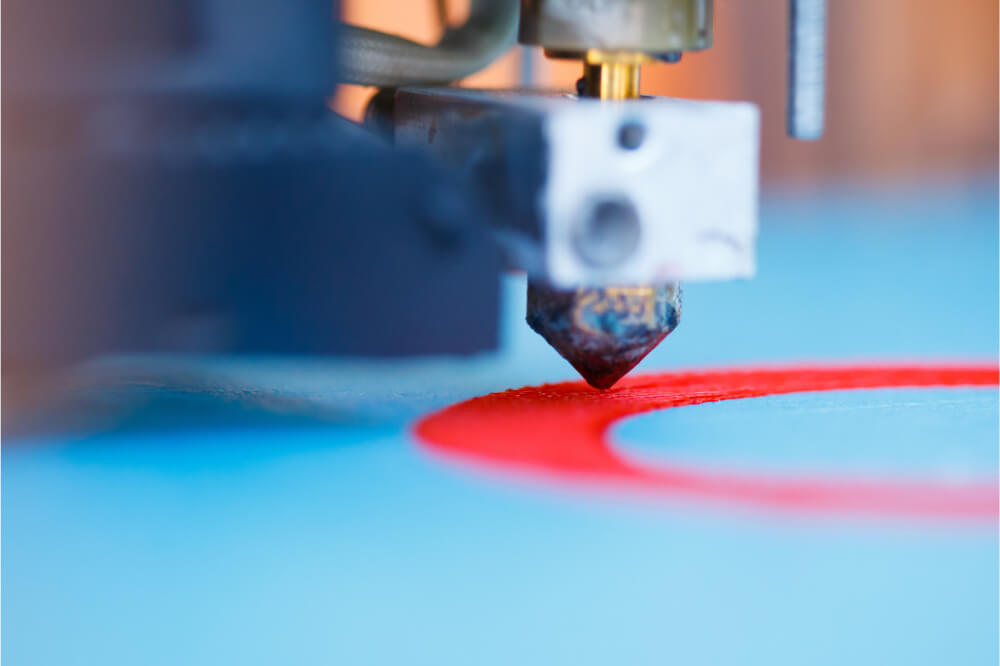

But as the old saying goes, ‘haste makes waste’ and the faster the printer goes, the sloppier the job and the lower the quality of the printing job. Also, the speed of the printer may out race the extrude rate of the filament meaning that there will be no color in some spots or a piece of the object is missing.

The good news is that once you select your print speed, the software should calculate the duration time for you so you know exactly when the printing will be done.

How to influence the speed of your printer

There are ways to help your 3D printer pick up the pace. The following chart will explain those options to you.

| Options | Explanations |

|---|---|

| Size matters | The bigger your object the slower the printing will go. That goes for taller objects as well |

| Print style | SLA method or printing is faster than FDM in most cases but the quality of the latter falls behind the SLA method. Speed depends on height of the object |

| Printer type | Delta models seem to be the fastest over the XYZ models by 15% or 30 minutes for a 4 hour print task |

| Layer height | The taller the layer the slower the printing. This can be adjusted through your software |

| Infill settings | Alter these to speed up or slow down the printing process. Higher infill densities take a lot longer than low infill densities |

| Nozzle size | The smaller the nozzle opening the slower the printing will go. Opt for a larger nozzle to speed things up |

There is one word of caution you should think about as it will help you adapt to 3D printing a lot better– “3D prints aren’t as easy as File > Print > Confirm”– You have to do a lot more thinking and apply more settings to get the job done.

How long does it take to print…?

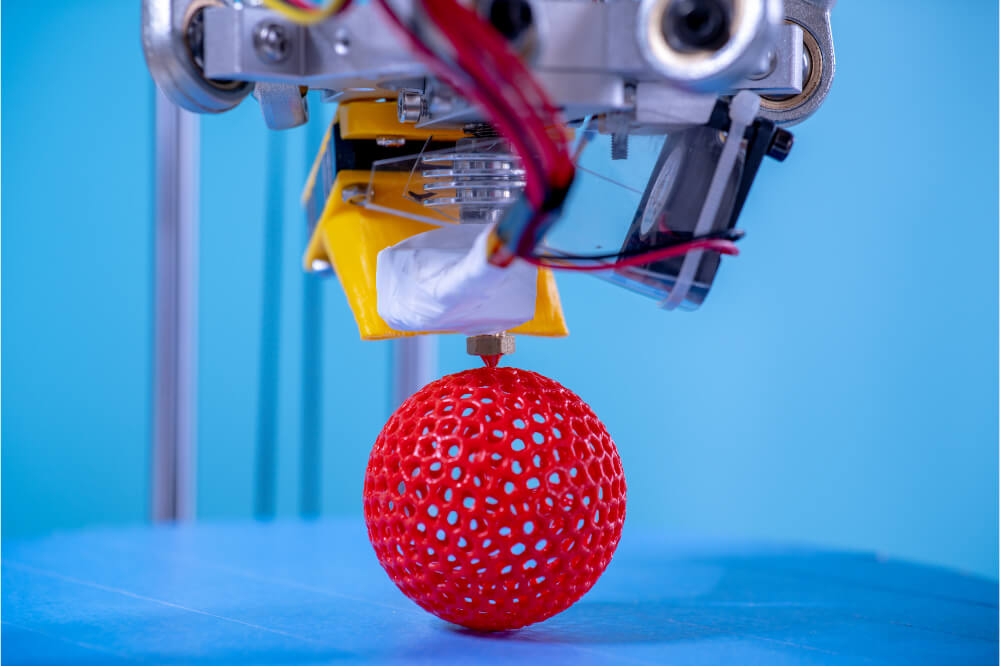

The following examples are not original with us but they are good examples to give you an idea of how long it takes to print different objects:

#1. small objects— anywhere between 30 minutes to over 10 hours. All the factors above play a role in the amount of time it takes

#2. prosthetic hand— full hand with thumb 6 hours & 31 minutes; the hinge takes approx. 2 hours & 18 minutes; 4 fingers were 5 hours & 16 minutes

#3. a face mask— between 2 and 3 hours but it is not a cloth surgical mask

#4. star wars helmet— 30 hours from start to finish and sometimes up to 50 hours

#5. a house— depending on the size, 24 hours up to 45 days

The smallest object a 3D printer can generally make on average is a 1 by 1 by 1 mm object but the world record is 0.08 by 0;1 by 0.02 mm

Why is everyone not using a 3D printer?

With everything that can be printed by a 3D printer, people are amazed that not everyone is using one of these devices. But there are good reasons why it is taking other people to jump on board and use 3D printing in their lives. Here are some of those reasons:

- They are waiting for the right affordable model. There are some cheap ones and some assembly required but they are not that definitive model everyone is looking for.

- The expense of some models- the SLS 3D printer can run as high as $250,000. Good thing the patents have expired so the price may come down.

- Patent and other legal issues- the patents for the original 3D printers expired roughly in 2014 but there have been over 700 more patents filed every year between 2006 & 2014. It may take a while to sort things out.

- Their usefulness is still questioned- Some things are fine to print but beyond sitting on your shelf what good are they? That attitude may have changed by now.

- Quality of the plastic filament- this too may have changed over the years but sturdiness may still be an issue.

- The devices are slow- this is a big drawback even today. People want things done now, not 3 days from now.

- Complex software and not user friendly- the 3D printer needs to be like the normal 2D all in one printers before people will use them.

Some final words

3D printers are slow because there is so much involved in the printing process. These are not like the typical 2D printers where you push a button and the printing is done in seconds.

There are just too many factors to coordinate before you get a good 3D print. Then you have to decide what to do with the finished product. Selling them may not be an option.