If you’re a professional or DIY enthusiast who enjoys doing soldering projects, you appreciate the importance of the soldering iron. This tool usually works by producing electricity at high temperatures which exceed the metal’s melting point. Thanks to this, the solder gets to flow between the workpieces that are required to be joined.

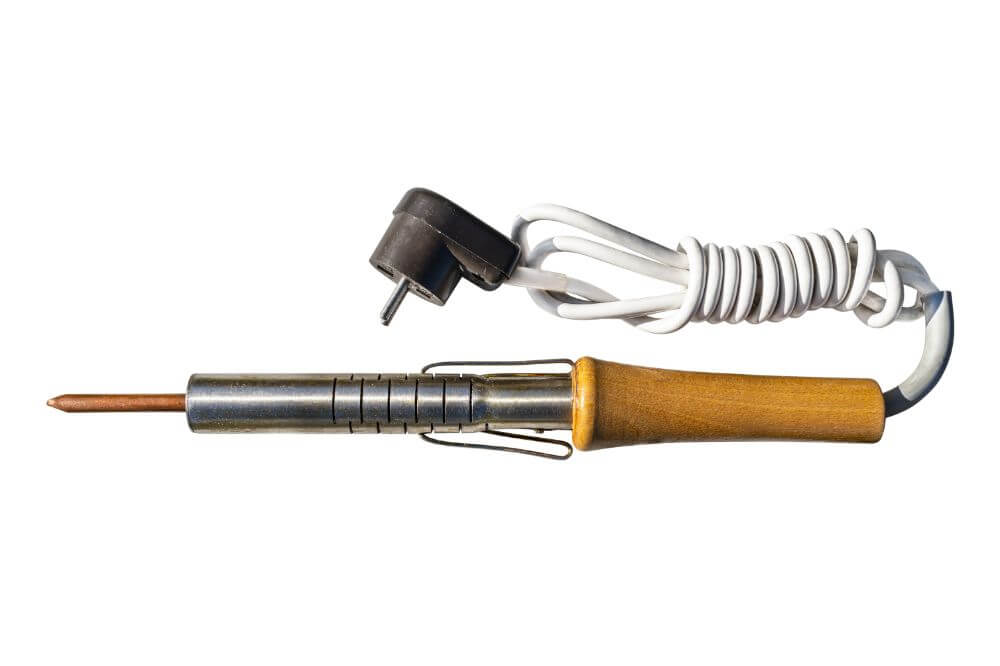

After using the soldering iron for some time, one of the distinguishing features you’ll notice is a metal iron tip. This tip plays an integral role in this tool as it’s the point where the heat gets delivered onto the solder.

But one curious observation you must have realized is that the tip is usually made of copper. So why is this generally the case? If this is also something you want to know, you’ve come to the right place. Here is a detailed article on why copper is usually the preferred metal used on soldering irons.

Reasons Why Copper Is Used On Soldering Irons

Affordability

There are other metals such as gold and silver, which are excellent conductors of electricity. Nonetheless, these metals are prohibitively expensive and don’t make sense to use them as the tip of the soldering iron. If used, this would drive the prices of this essential tool very high, making it inaccessible to most people.

Conversely, copper is much cheaper than these two metals mentioned above and still guarantees exceptional heat conductivity due to its low thermal resistance. For this reason, many manufacturers opt to install soldering tips that are made of copper instead of other metals.

Excellent Thermal Conductivity

One of the main reasons copper is considered the ideal choice over other metals is its superb thermal conductivity, which translates to low thermal resistance.

Since copper has a greater thermal conductivity, it transfers heat a lot faster than other metals with lower thermal conductivity. This means a soldering iron with a tip made from copper does a better job transferring heat more quickly onto the solder.

Moreover, copper’s thermal capacity is another reason this metal is considered an ideal choice for the soldering iron tip. And whereas this difference is minimal between other metals such as silver, iron, bismuth, or brass, especially for a small part like the soldering tip, it still does matter.

Low Electrical Resistance

Copper is also preferred due to its excellent electrical conductivity, which makes it have low electrical resistance. This is essential when making a soldering iron tip regardless of its mass type since it needs to pass down the heat to the solder without experiencing a great internal heat gradient.

For instance, if you decide to use a soldering iron tip made using iron, its heat gradient will become extremely high such that the tip doesn’t have enough heat to melt the solder. This is despite the heating element producing more than enough power to heat things.

How To Maintain Your Copper Soldering Tip

Whereas copper is the ideal tip for your soldering iron, it still needs to be maintained or risk destroying it. Here are some useful maintenance tips you should implement.

Properly Storing Your Soldering Iron

Where you decide to store your soldering iron has a direct impact on how long this tool lasts as well as its performance. Thus, it’s vital to make sure the soldering iron is stored in a suitable storage location to safeguard it from damage.

Ideally, this means cleaning your soldering iron tip before storing it away when planning not to use it for a prolonged duration. By doing this, you’ll lower the chances of the copper tip being destroyed due to oxidation, contamination, or humidity. When storing the copper tip for a short duration, for instance, in between soldering sessions, place the soldering iron on a secure iron holder. As you do this, make sure it isn’t at room temperature because this will lower the tip’s life.

Avoid Too Much Heat

Another common reason that might cause your soldering iron tip to get destroyed is excessive heat. You should avoid this by making sure to always use proper temperature depending on the task being carried out. If you overlook this and leave your copper soldering iron tip at high temperatures, it runs the risk of getting destroyed. This reduces the tip’s life, thereby necessitating you to find a replacement sooner that you ought to.

Cleaning Your Soldering Iron Tip

Cleaning the tip of your soldering iron doesn’t only improve the soldering iron’s performance but also extends its life. Therefore, you need to clean your soldering iron tip before, during, and once you’re done using it, with a clean tip looking shiny and bright.

Before you start soldering, it’s essential to remove contaminants such as oxidation, corrosion, and grease from the surface you want to solder using a clean cloth and alcohol. It would be best if you also used stainless or brass steel wool when cleaning your soldering iron tip. Stainless steel wool is an ideal choice as it boasts a longer life, whereas brass wool is less abrasive and softer.

Use High-Quality Solder

An excellent way of guaranteeing the copper tip of your soldering iron doesn’t get destroyed as fast is by using a solder of exceptional quality. This is a better choice than low-quality solders, which have impurities that may accumulate on the tip. As a result, this restricts heat transfer from the soldering iron, making your soldering duties a lot more challenging.

You should thus opt for high-quality brass from a reputable brand to prolong the life of your soldering iron tip. One way to identify a high-quality solder is that it should melt quickly at the anticipated temperature. This is something that a low-quality solder won’t guarantee, which directly impacts the tips life.

Conclusion

Soldering irons made of copper are popular among both DIY enthusiasts and professionals. If you had no idea why exactly this is the case, reading through this article has shown you why this is usually the case. Now that you know this, it’s evident why you should prioritize buying a soldering iron tip made from copper rather than that made from other metals such as brass or silver.