It is always smart…

To have great ventilation when working with different devices. Not only does a good air flow keep the air clean and healthy to breathe but it also helps keep different device motors cooler so they last longer.

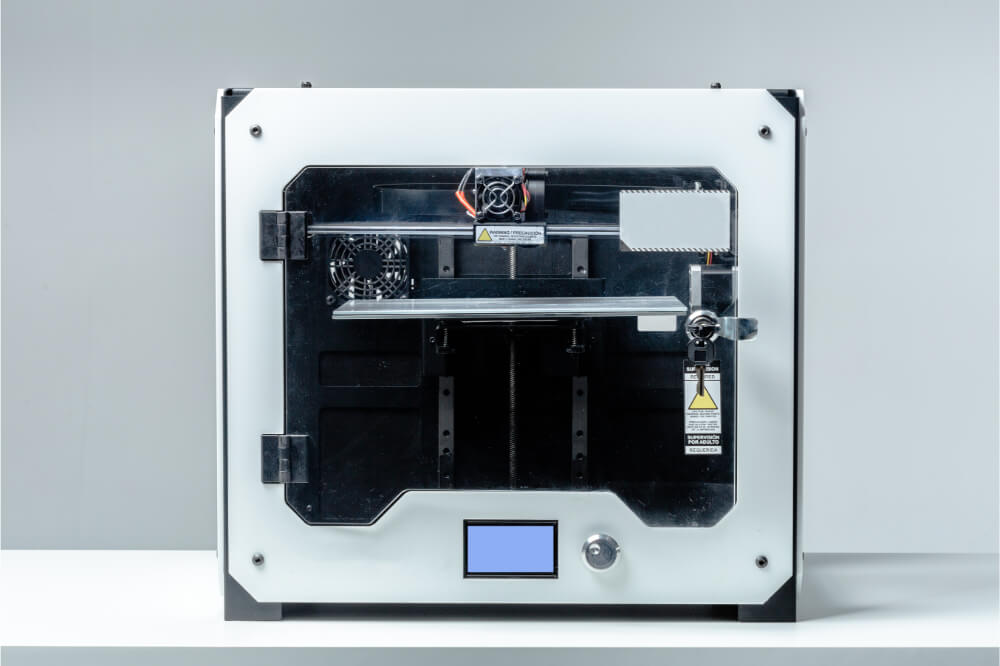

3D printers are no different. Because they work with heat and melt plastic it is a smart idea to keep your work area well ventilated. The fumes from some of the filaments do not smell that good nor are they friendly to your lungs.

To learn more about 3D printer ventilation just continue to read our article. It has the tips and bits of information you need to know about to have a safe printing area.

Do 3D Printers Need Ventilation?

Yes, they do. Different studies dating back to 2012 to 20-14 have found that these printers emit hazardous fumes and particles into the air. If you breathe them in, then you are taking a big risk and helping different diseases to form.

A good ventilation system helps bring in good air as it disperses the bad. Plus you should have one of these no matter what type of 3D printer you own. The heat process can get too hot and then you may be seeing smoke or flames erupt at the wrong time.

A good ventilation system helps keep everything cool and within working parameters.

Some 3D printer guidelines

Even though you have a fairly good ventilation system, there are some guidelines to help you set up a better work space and make 3D printing safe for you, your family and your co-workers/employees.

| Number | Guideline | Description |

|---|---|---|

| 1. | Closed printing bed | These help contain the particles and fumes as well as help direct them to your ventilation ducts |

| 2. | Follow all manufacturer’s instructions | These will help you handle the materials properly as well as give you safety advice |

| 3. | Location of printer | To minimize escaping particles place the 3D printer as near the ventilation grill as you can |

| 4. | Spectators | While the printer is doing its job keep observers far enough away so that they do not breathe in fumes and particles |

| 5. | Non-printing activities | Because some of the resin and other material,,as well as particles, can get on your hands, ban eating, drinking,handling contact lenses as well as applying cosmetics while the machine is running |

| 6. | Keep hands clean | Those particles can and do the device, the build bed, and other spots. Then when you touch those spots, those particles get on your hands.always wash your hands after touching the 3D printer and surrounding area |

| 7. | Cleaning around the printer | Do not use a broom or a dry cloth to sweep up any articles. Those items return the particles to the air. Use a wet cloth, HEPA vacuum or wet sponge instead |

| 8. | Watch the use of IPA | This is a good resin cleaner but once you clean up the toxins and particles, IPA becomes toxic. Don’t let used IPA touch your skin |

| 9. | Use cold water | Hot water will open up pores and let any spilled resin or other chemicals be absorbed into your skin. Always wash up using cold water |

How to ventilate your 3D work area

There are steps to follow when you are looking to make your 3D work space more user friendly. Here are those steps to follow:

#1. Analyze your ventilation needs

This is important as a careful study of your 3D work area helps you design the right ventilation system as well as set some good rules

#2. Know your 3D operation

The average 3D printer runs for about 5 to 7 hours every day so your ventilation system needs to be able to handle the workload.

Both SLA and FDA printing methods produce airborne particles, VOCs and styrene. Make sure your ventilation system redirects those harmful elements away from your workers, etc.

#3. Know your spaces

An enclosed space is an area that has too few windows or doors, no real ventilation system that opens up to the outside. An open space is where you have enough windows, doors and ventilation fans that provide great cross wind air flow.

The former situation needs lots of work while the latter doesn’t and will cost less to ventilate.

#4. Know your options

If you cannot afford a good ventilation system, then maybe you can install a good air purifier that comes with a HEPA or charcoal filter. Make sure to get one that is rated for the size of room the 3D printer is located.

Or you can use an air extractor and these can be as affordable as an air purifier. There are several types you can choose from. Just make sure it can handle the room size.

Is ventilation needed with 3D printers

The biggest concern when it comes to using a 3D printer are the different harmful elements you can inhale if you stay in the room while the machine is printing. When you are working with ABS and other filaments, powders or resin that give off toxic fumes and particles, then yes, ventilation is needed.

Nylon is another material used in 3D printing and you need a good ventilation system to handle those toxins as well. Whenever you are working with chemicals and heat ventilation is a must.

When you do not need ventilation is when you are working with safe 3D filaments, resin and powders. This means you need to know your filaments, etc., before you set up your 3D work place.

Some final words

They say it is better to be safe than sorry and that old saying applies to 3D printing as well as other industries. Know your 3D printer, what kind of fumes and particles it gives off and which materials are non toxic. This way you can build the right ventilation system and protect everyone involved with your work.

Staying safe is a top priority when working with plastics, heat and other hazardous materials. Create your own guideline list to help remind you to stay safe.