It is a very good question…

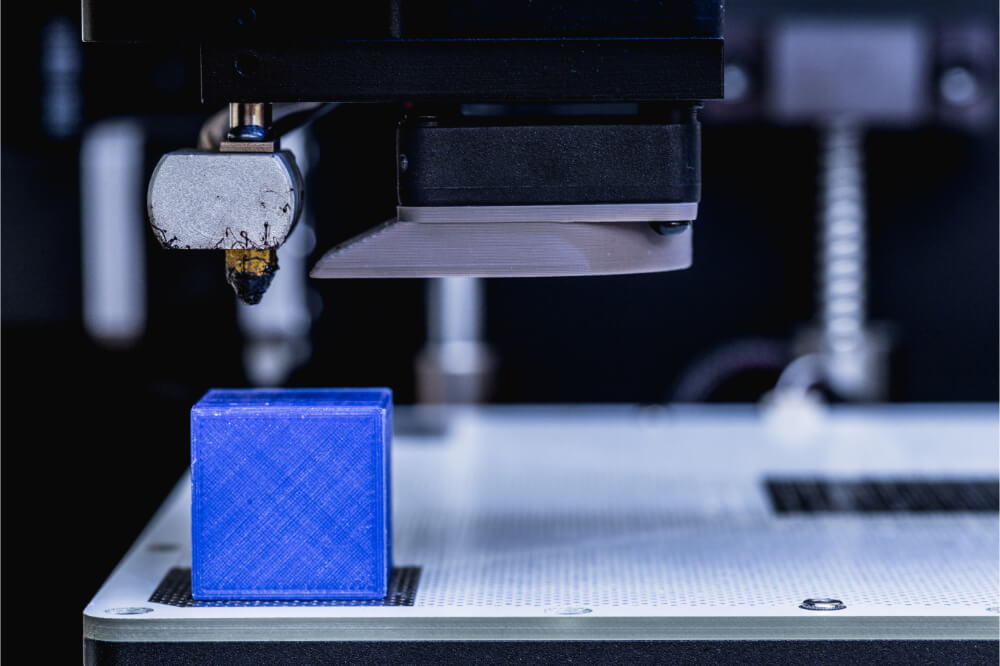

With the way technology moves these days, it is hard to know what filaments are available to do your 3D prints. Plastic is the most commonly known filament used by almost all 3D printers at some point in their printing careers.

It is a simple filament to use and it comes in different varieties so you get different qualities, colors and styles of prints. Which filament you use is up to you and the type of printing projects you want to do.

To find out the different printing materials 3D printers can print in, just continue to read our article. It has the information to help you broaden your printing ability.

What material do 3D printers use

Plastic or its correct term, thermoplastic,may have been the original material used in 3D printing but over the years technology researchers have been able to add different materials to the plastic filament. Those options, called composite filaments, take on the property of the added material so technically they are not true plastic.

Then there are the different resins that have been developed. This is a liquid filament and it may be stronger and better than the solid thermoplastic filaments used in most 3D printers.

The drawback is their expense, the resin can cost about $100 per liter. The style of printing used for resin based printers is SLA and the printer can cost in the tens of thousands.

There is a recycle plastic option but you need a different machine to create that filament and the quality of the plastic retrieved is not that great.

Types of filaments available for printers

Setting resin filaments aside, due to their high cost, here are some plastic and composite filaments that you can use. The prices of these options have been mentioned in other articles so that option will be left off this chart.

| Filament | Properties | Usage | Printing temperature | Bed temperature | Bed adhesion |

|---|---|---|---|---|---|

| ABS | Durable, strong easy to print | Innumerable objects from Legos to instruments | 210 to 250 C | 80 to 110 C | Kapton tape/hairspray |

| PLA | Odorless, eco friendly, uses less energy | Food containers, medical items, prototypes | 190 to 230 C | 60 to 80 C | Blue painter’s tape |

| PVA | Non-toxic, eco friendly, dissolves in water | Packaging film, paper adhesive, etc | 180 to 230 C | 45 C | Blue painter’s tape |

| PET | FDA approved for food containers, no odors or fumes | Flexible for phone cases, jewelry & electronics | 230 to 255 C | 55 to 70 C | Blue painter’s tape |

| PETG | Very durable, no odor, impact resistant | For phone cases and objects needing flexibility | 220 to 245 C | 70 to 75 C | Blue painter’s tape |

| PETT | Colorless, FDA approved, recyclable, strong | Food containers, utensils, soft drink bottles | 210 to 230 C | 45 C | Blue painter’s tape |

| HIPS | Biodegradable, support material | Models, mini figurines, prototypes | 220-230 C | 50 to 60 C | Kapton tape or hairspray |

| Nylon | Strong, durable & lightweight | Machine parts, mechanical components | 210 to 250 C | 60 to 80 C | PVA based glue |

| Wood | Smells like wood, versatile, durable, has real wood fibers | Wood boxes, figurines, furniture | 200 to 260 C | 90 to 110 C | Blue Painter’s tape |

| Sandstone | Doesn’t feel like plastic. Decorates easily, little warp if any | Architecture models,landscapes | 165 to 210 C | 20 to 55 C | Blue painter’s tape |

| Metal | Very durable,little shrinkage | Jewelry, statues, home hardware items | 195 to 220 C | 50 C | Blue painter’s tape |

| Magnetic PLA (Iron) | Has magnetic properties and durable | Fridge magnets, sensors, DIY projects | 185 C | 20 to 55 C | Blue painter’s tape |

| Conductive PLA | Low warp, circuits, low voltage electronics | Sensors, circuits requiring little voltage | 225 to 260 C | 90 to 110 C | Kapton tape or hairspray |

| Carbon fiber | Durable, water soluble, low warp | Frames, supports, tools | 195 to 220 C | 50 C | Blue painter’s tape |

| Flexible or TPE | Resists cuts, smooth, durable | Toys, novelty items, phone cases | 210 to 225 C | 20 to 55 C | Blue painter’s tape |

| Glow in the dark | Low warp, glows, durable | Toys, novelties, clothing | 185 to 205 C | 70 C | Blue painter’s tape |

| Amphora | Strong, food contact compliant, no odors | Desktop items, mechanical parts | 220 to 250 C | 60 to 70 C | Blue painter’s tape |

The pros and cons of resin 3D printing ink

It is said that this style of printing will become more accessible in the coming years. If that is the case, then you should know about the different positive and negative aspects of this style of 3D printing.

Pros:

- Better resolution- your object looks a lot better and the quality depends on the type of laser being used to make the print.

- Faster printing times- resins do not have the weight drawback that regular filaments have so your prints are made quicker without sacrificing quality.

- Printed objects are stronger- the different painting techniques build the strength of the object making them more durable and tougher to ruin.

Cons:

- The cost- the printer itself is over $1,000 and while it depends on where you buy the resin, you can pay up to $100 per liter.

- No flexibility- by this regular 3D filament printing allows for changes in the filament, and style of filament and still print the object. With resin printing you are stuck with one resin style only. This cuts the creativity level down.

- Post processing can be messy- it has to be done then you have to clean up the mess. This is a deal breaker for some people. Limited availability of the resin and printers.

Some final words

To get away from plastic printing, you either have to use a composite filament or upgrade to the limited resin style of 3D printing. Most of the filaments involved with desktop 3D printing are made from plastic and the quality you get depends on the quality of the filament.

There are some food based, edible filaments which should not be made from plastic but that is a topic for another day.