Every job has a proper procedure…

These procedures help a workman do their job quickly and efficiently when followed correctly. Tinning a soldering iron tip only takes about a minute of your time and it is over before you know it.

To learn how to tin your soldering iron just continue to read our article. It gives you the step by step process so you can protect your soldering iron tips and have them last a long time.

Why do you need to tin your soldering iron tips?

Tinning your soldering iron tip is a process that helps protect those tips from any oxidation that may occur as you work. It also helps them last a long time. That is money saved and in your pocket.

Almost all soldering iron tips are iron plated copper metal. For the tip to work like it should you need a thin layer of solder coating that iron plating. If you don’t do this, the solder may not melt very well or very fast. Plus, you won’t do a very good job.

The tinning process

Here are the steps you need to take in order to ensure that you have tinned your soldering iron tip correctly:

| Step | Title | Explanation |

|---|---|---|

| #1. | Cleaning | This has to be done before, during, and after you use the soldering iron tip. A thorough cleaning prior to use is mandatory. During use, you can wipe with a wet sponge and then after use, just clean the tip like normal |

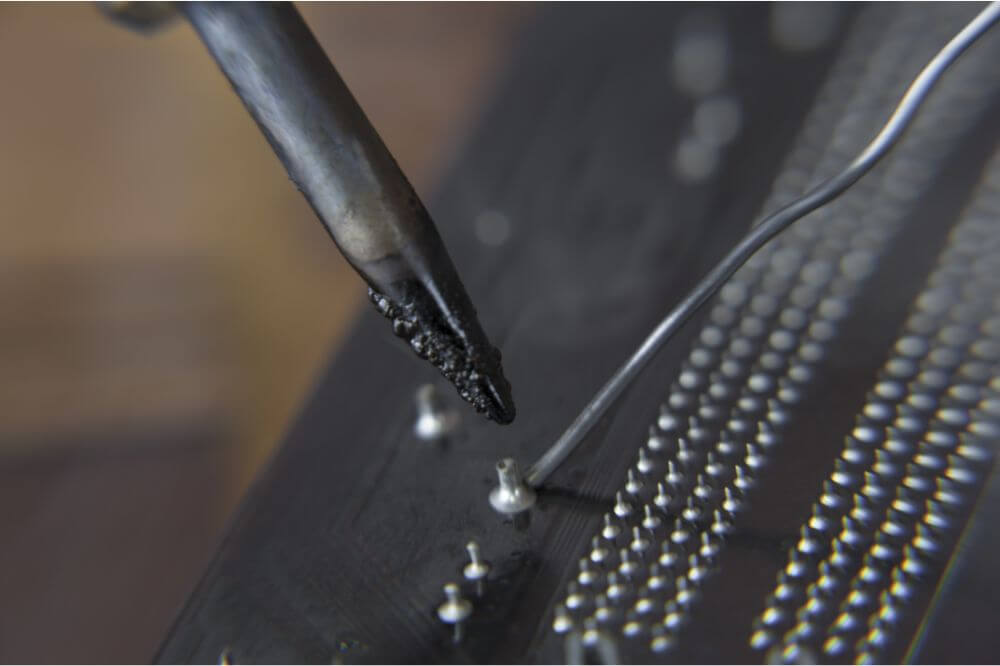

| #2. | Tinning | After your tip heats up a little, apply a thin layer of solder to the tip. The rosin in the solder will help it adhere to the tip and give it a nice shiny coat. Place a little flux on the tip prior to adding the solder layer. Some people wrap solder wire around the tip, others just place the solder wire end on the tip and let it melt. |

| #3. | Testing | After the solder has coated the tip, you can do a test to make sure the tinning process was successful and that it will melt the solder correctly when you are working. |

Cause for detinning of the tip

It is possible for the tips to lose their solder coating. When it does it is called detinning. When you see the surface of the tip turning black you know that it has lost its solder coating and needs to be retinned.

Here are some causes for the soldering iron tip to lose its solder coating:

- When you wipe the tip on a dry sponge, a rag, paper towels, or even steel wool the coating can come off

- Not retinning the tip when it will be in storage for a long time

- Using the wrong solder that contains a low tin content

- Using the tip at 800 degrees F or higher. You should always stay below that benchmark

- The failure to use enough flux when working with the soldering iron

- Using solder wire that is too small in diameter. Not enough flux hits the surface of the tip or the items being joined together

How to restore your detinned soldering iron tip

When you see that your tips have lost their tinning coat, you do not have to throw the tips away. There are several ways to restore the tinning and keep the tips with you for many more years

| Number | Technique | Explanation | ||

|---|---|---|---|---|

| 1. | A polishing bar | This is filled with abrasive material that will remove surface oxides. All you do is rub it on the tip till the shiny metal appears again | ||

| 2. | Tip cleaner | This is a paste that you dip your tip into to clean it up. The soldering iron should be set at about 750 degrees, hold the working tip in the paste for 5 seconds, turning it to the right and left. Wipe the paste off with a wet sponge | ||

| 3. | Soldering wire with a rosin based flux | Use sandpaper first to clean the tip off. Then wrap some of this solder around the tip. Then turn the soldering iron on and let it get to 750 degrees F and let the solder melt. Clean with a wet sponge | ||

| 4. | Bronze or soft steel brush | Like using sandpaper just rub the brush over the tip. When the oxidation is off cover the tip with solder once again5. | Emery cloth | Same as above |

One warning— never use a file to clean the soldering iron tip nor use the file to reshape the tip. The file will remove the iron plating and expose the copper tip and you risk having it melt into the solder.

How to tin copper wire

This is a very simple process and like tinning a soldering iron tip it only takes a very short time to get done. All you need to do is heat your soldering iron up and touch the tip to the end of the wire you want tinned. This connection should only last for a very short time.

Once that is done, touch the solder to the end of the wire and let it melt and cover the wire end. If the solder creates a little ball at the end of the wire, just snip it off. Also, try not to overheat the wire as you will melt the insulation and expose too much wire.

Some final words

As you can see tinning is not that difficult and it does not take up a lot of time. It is worth the effort as you will do a better job soldering and the tips will last you a very long time.

Following the correct procedures makes any job simpler and more enjoyable. You will have fewer problems when you take the time to do everything right. The keys are to make sure you use the right solder with the correct amount of tin inside and that the solder is not too small.

Then make sure to clean your tips and retin them at every opportunity.