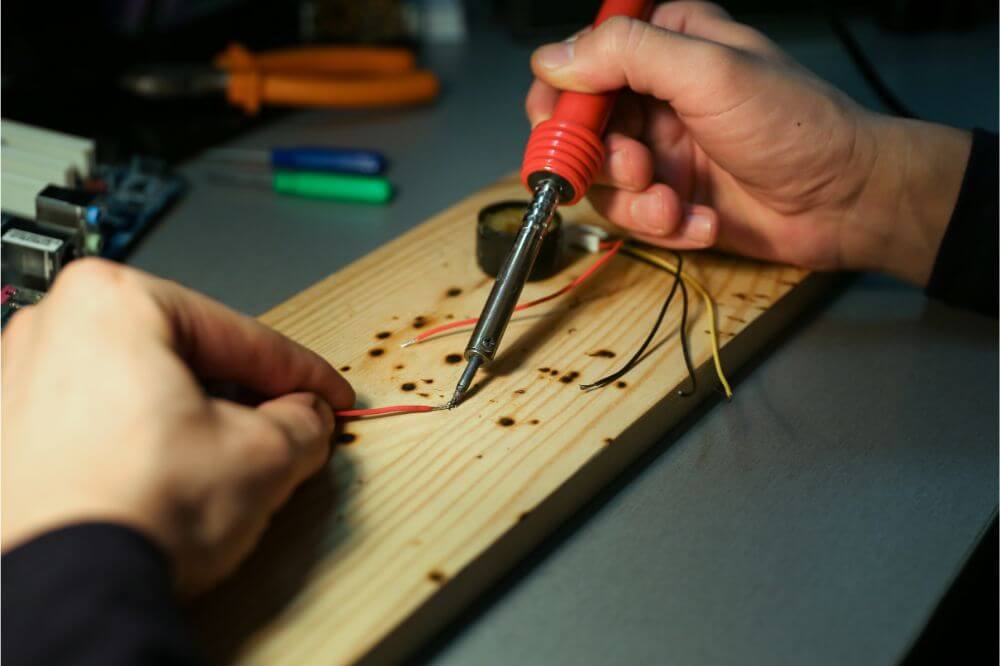

Knowing how a soldering iron heats up

Soldering different components and wires together is a skill. It is a handy skill to have and when you are a beginner, it helps to know how long and how a soldering iron heats up. That way you can plan your project accordingly and make your work more efficient.

To learn how a soldering heat up and how long it takes just continue to read our article. It has the information you need to improve your soldering skills. Adding to your talents is always a handy habit to get into.

How does a soldering iron heat up

For the most part, the majority of soldering irons are electric. They come with an electrical circuit that heats the element which then heats the tip of the iron. That heating element is made up of resistance wire that is wrapped around a metal spool.

When you plug the soldering iron into the outlet, the electrical current transfers to the iron and starts to heat the wire, which then heats the metal spool. That metal spool then eventually transfers the heat to the soldering iron tip.

This process can take a long time to complete so you will need some patience when you take up soldering.

Different types of soldering irons

Not every soldering iron works the same and there are several different types of irons you can use for different soldering chores. How long each one takes to heat up depends on the iron and there is no set magic number to go by.

| Number | Soldering iron | Purpose |

|---|---|---|

| 1. | Pencil soldering items | These are non-temperature controlled and are a plug and play tool. They may take a few minutes to heat up |

| 2. | Soldering gun | These have two transformers in them. One to convert the voltage to a lower current and one to convert to a higher current and the latter heats the tip |

| 3. | Soldering station | May be quicker to heat up as they have a temperature-controlled dial on the station. The station usually will sit on a workbench. |

| 4. | Temperature controlled soldering irons | Sensors monitor the temperature and help keep it steady then a thermostat on the tip turns the heat on and off to control the temperature. May be a bit slow in heating up |

| 5. | Soldering tweezers | They may be small but they are a perfect tool for tight spots. Their small size may have them heating up quicker than other models |

| 6. | Hot knife | There may not be a temperature control on this version but it will get to over 1000 degrees F. |

| 7. | Cordless or battery-operated soldering iron | These are not large irons and can heat up fairly quickly. They are also powered by butane. There is no way to control the temperature levels on these models. |

Soldering iron operation

The different designs of the soldering iron do influence the time it takes for an iron to heat up. Some will move a lot quicker as there is less resistance and the heat can travel faster.

For the most part, all you have to do is plug in the power cord and wait. This is true for almost all soldering irons made for household use. Also, if the iron is of good quality, then it will heat up much faster than we have implied.

Inferior quality soldering irons are not that efficient. Once you get ready to use your soldering iron, you should clean it first and then let it heat up so you can tin it. After tinning, do a test to make sure you got that part correct and that it is hot enough to melt the solder.

When you see that it is hot enough, apply the solder and the iron to the components you want to be connected. That is all there is to the basic soldering tasks.

Troubleshooting your soldering iron

If this was a perfect world, this is a problem you would never face. But since it isn’t it is important to learn some troubleshooting tips to help you stay on your soldering schedule.

- The heating element does not heat– then there is a break in the circuit, a bad wire, or a short somewhere. When this happens you need to replace the heating element or wires.

- Heat is generated but the tip is cold– the problem here is the soldering iron tip. The source for this problem is bad tinning, failure to keep the tip clean, or oxidation. Clean and retin the tip

- Gas-powered iron generates no heat– this is a simple problem to solve as you may be out of fuel or something is clogging the fuel line. Replace the fuel or unclog the line

- Battery operated iron not generating heat– the batteries have used up their power or there is a loose connection or a short in the system. Replace the batteries and if there is no heat then check the wires for a loose,m broken, or shorted wire.

- Soldering station not working right– this may require the aid of a professional electronics repair person as these devices, unlike their counterparts, are a bit complicated.

- Temperature controlled iron not heating up– besides the usual sources for this issue already mentioned, there may be a problem with the temperature control dial. This problem too will need the help of a professional repairman

Some final words

The heating process is the least of your concerns until something goes wrong with the system. Normally, all you have to do is plug in the devices, set the temperature level, and wait.

How long these different irons take to heat up depends on how they were made and the quality of the pats put inside of them. But once they do heat up, they will help you make great connections and have your work look professional.

The key is finding the right soldering iron to match up with the different soldering chores you need to be done. That is not as hard as it sounds.