Usually, solders have a relatively low melting point when compared to other alloys out there. Since they are equipped with a low melting point, you can melt it using a 40W iron; however, sometimes a soldering iron might not melt your solder. In most cases, this is due to insufficient heat transfer or faulty soldering iron.

In addition to these, there are other various reasons as to why a soldering iron might not melt a solder. As a result, in this article, we shall be discussing why your soldering iron may not be melting solder.

What Causes A Soldering Iron Not To Melt A Solder?

This is a question worth discussing. Some of the reasons as to why a soldering iron might not melt a solder include:

- Oxidized soldering iron tip. This is highly common and tends to occur when a soldering tip is left bare at a high temperature.

- Poor soldering technique. Mastering soldering technique aids in boosting your soldering skills significantly. With an inadequate soldering approach, melting soldering with a soldering iron even can be relatively challenging for most.

- Insufficient heat supply. When the heat transferred to the soldering iron tip is relatively low, melting a solder will be impossible.

- Dirt and oxidized parts. When copper is exposed to air for an extended period, it tends to oxidize fast.

Oxidized Soldering Iron Tip

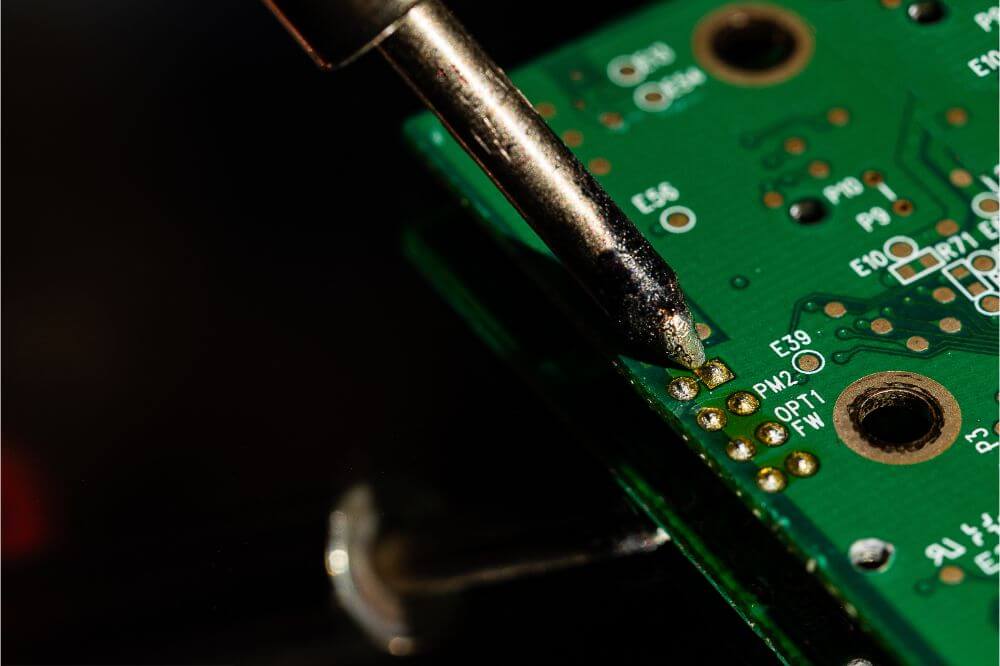

Soldering iron tip is vital since it supplies the heat used in melting your solder, allowing it to melt and flow into the joint between your workpieces.

However, when oxidized, a soldering iron tip cannot transfer heat from the heat source to melt your solder. If your soldering iron is not melting your solder, you should consider assessing it for impurities and oxidation layers on its tip.

If present, you should consider getting rid of the oxidized layer on the tip of your soldering iron. It would be best if you considered globing your tip every time you set the soldering iron down. This will help improve heat transfer and facilitate the melting of your solder.

Poor soldering technique

A poor soldering technique will determine whether or not your solder will melt. You will need to apply solder to your soldering iron and let it sit there for a short while before carrying it to the joint. When you let your solder sit on the soldering iron, the flux will start boiling fast; usually, the fumes are from the flux and not lead.

Without flux, the soldering process will become almost impossible. When using flux, you will be able to get rid of the oxidized layer from the metal. It is vital since your solder will not stick to a metal with an oxidized layer, and usually, metals tend to oxidize faster in soldering temperatures.

For your solder to melt effectively, you will need to master good soldering techniques. You will need to hold your soldering iron tip allowing it to get much contact with the component you are soldering. During the process, add a small amount of solder between the element and the tip allowing it to act as a heat-bridge.

Once that is done, you will need to add solder to the opposite side of your new joint. By doing so, the solder will run towards the source of heat, allowing you to spread the solder out. In this process, the solder will melt and adhere to your component, creating a reliable bond.

Insufficient Heat Supply

Solders are designed to have a relatively low melting point; this means that with a 15-watt soldering iron, you can still melt small chips solders. However, when working with larger connectors or wires that are relatively bigger than 16 gauge, 15 watts soldering iron will be not be effective to melt the solder.

As a result, you will require 25 to 30 watts soldering iron; these soldering irons are often considered the best for hobby applications. If your solder is not melting, you should always check if the wattage is sufficient for its size.

Usually, with the right wattage, you can melt your solder with the utmost ease. Wattage is the amount of heat that can be supplied by your soldering iron. In principle, this is independent of the temperature of your soldering tip. The wattage supplied to the tip of a soldering iron is regulated to help in maintaining a stable tip temperature.

Wattage is the maximum heat output. However, some tips are equipped with a simple heater that generates rated heat; this means that the temperature of your soldering tip will vary significantly. With a 15-watt soldering iron, the tip will reach 550 degrees Fahrenheit and a 40-watt soldering iron, its tip will reach over 800 degrees Fahrenheit.

Generally, it would be best if you always settled for soldering iron with a temperature between 650 and 750 degrees Fahrenheit while working with lead-based solder. On the other hand, a soldering iron with more than 800 degrees Fahrenheit is considered the best for use when working with lead-free solder. These factors often have a significant impact on the temperature levels of your soldering iron tip.

Final Verdict

By maintaining your solder’s tip, you will be able to improve the melting time of your solder. One of the common factors that inhibit melting of solder is the oxidation of the soldering iron tip. You should note that oxidation of the soldering tip can occur at room temperature, however, at a slower rate. Therefore, the soldering heat will accelerate this process.

With oxidation being considered as the most significant factor affecting tip heat transfer and melting period of solder, it is worth getting rid of it with all means possible. Oxidation is known for creating a thermal dewetting barrier, and when it occurs, your solder will ball up on the soldering tip rather than flowing smoothly.

There are several ways in which you can get rid of the oxidized layer and protect your soldering iron tip from oxidation. Always consider practicing these tips to help in improving the melting time of your solder and the overall functionality of your soldering iron.