Whether you are using a new soldering iron or an old one, calibrating it is very essential. As a solderer, it is advisable that you calibrate your soldering iron every week.

This is highly essential since the biggest setback when it comes to soldering is inaccuracy in temperature. By correcting this issue will help in enhancing the performance of your soldering iron significantly.

As your soldering iron and station gets older, its power tends to weaken. Your soldering station might have a temperature reading of 700 degrees Fahrenheit, but it is not the actual temperature. You even be soldering at 650 degrees Fahrenheit or lower than that.

When replacing your soldering station with a new one featuring an advanced handpiece, you might set it at a particular temperature, and it might be 50 degrees hotter. This will end up ruining the components you are working on or PCB. It is due to this that calibrating your soldering iron is crucial.

In this article, we shall be taking yours through how to calibrate a soldering iron. This process is relatively simple and very essential. When done correctly, you will be able to enhance your soldering experience and have the best final result.

Calibrating A Soldering Iron

When it comes to calibrating a soldering iron, you should always note that the process might differ from one soldering iron to another. However, in this article, we shall be taking you through the general steps involved in calibrating a soldering iron.

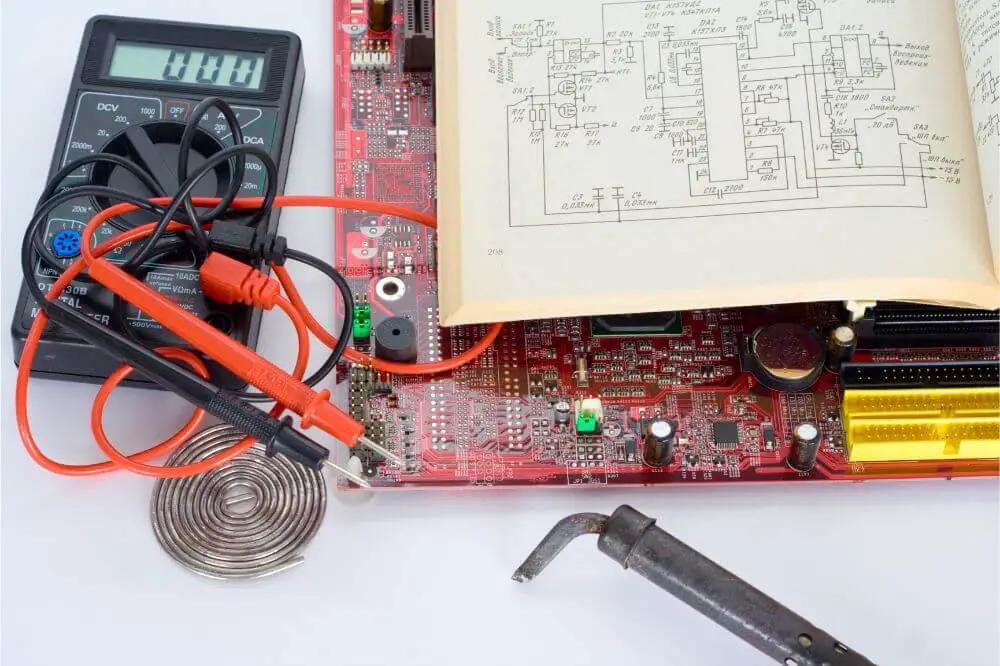

Installing the sensor

The first thing to do is to install a set of tip sensors on the tip thermometer. Ensure that these sensors have been looped onto the board of your thermometer. Once that is done, ensure that you match blue and red sides of the sensor wire along with the post marked with blue and red dots on your thermometer board.

The sensors need to be effective since thermocouples as well as polarity matters. You should note that each sensor will last approximately 30 to 50 measurements. Most measuring units come equipped with 10 in total, and replacing them is relatively affordable.

Testing your soldering iron

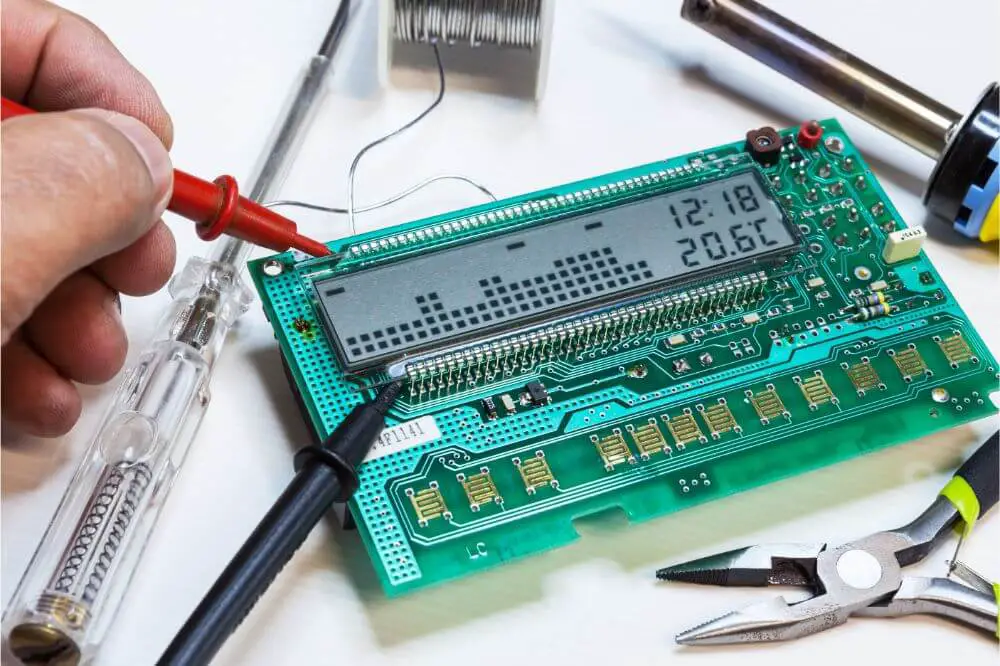

Once the sensors are installed in place, you should set the soldering iron to the temperature level you most desire. Afterwards, when the soldering station has attained the desired temperature, you should touch your soldering iron tip on the mind point of your sensor. While doing so, you should avoid pressing it down on the wire since it can cause your wire to stretch hence increasing erroneous readings.

It would be best if you continued having the soldering iron pressed against the sensor until your thermometer is through with the calibration. When the temperature levels of your thermometer stop going upwards, you will be able to read the accurate reading of the soldering iron as well as the soldering station temperature.

Once your soldering iron reaches the required temperature and then stabilizes, you should rest the tip flat on your sensor and then apply a small amount of solder to help create a heat-bridge. It would be best if you continued keeping the tip in contact with your sensor until you achieve the peak reading. It is highly recommended that you repeat this process two to three times and ensure that you are receiving the same peak readings. By doing so, you will be sure that you are doing the correct measurement.

The readings displayed on the digital display are the correct measurement of the soldering iron tip temperature measured by the tip thermometer.

What Is The Importance Of Calibrating A Soldering Iron?

The main reason for calibrating a soldering iron is to help in ensuring precise measurements. In addition to that, calibrating soldering iron tends to have significant benefits, including safety, profitability, as well as innovation.

Increases profitability

Usually, profitability is increased by either reducing costs or increasing revenues. The best part of calibrating a soldering iron is that it helps in doing both. Calibrating a soldering iron increases revenue by assisting you to produce high-quality products that will grant you good customer reviews.

In addition to that, calibrating soldering iron will help you save money by cutting down the cost associated with soldering error and recalls. You will be able to save a significant amount of money when you avoid soldering less durable joints and using excess energy to heat your solder.

Enhance accuracy

When it comes to soldering, accurate temperature readings are vital for a soldering process. To achieve precise measurement every time, you will need to calibrate your soldering iron continually. By doing so, you will be able to boost the production quality of your jewelry among other projects you will be working on.

It enhances safety

Soldering involves heating solder and melting it to join two different metals together. Since you will be working with metals at high-temperature levels, it is best to have a well-calibrated soldering iron that will offer you an accurate reading. This will provide you with precise reading allowing you to work in a safe environment. You don’t want to handle a hot solder with your bare hand due to an incorrect temperature reading on your soldering station.

Final Verdict

As a solderer, you need to ensure that your soldering iron, as well as your soldering station, meets accuracy along with repeatability requirements. It is highly recommended that you assess every heating element in your soldering iron and station. Calibrating your soldering iron will help boost your productivity and efficiency significantly.

Since soldering iron tends to differ from one manufacturer to the other, you should always calibrate your iron with specialized configuration. This will help you achieve the required standard.

You should as well calibrate your soldering iron tip in regards to leakage voltage, the temperature of your soldering iron tip as well as resistance. By correcting this issue, melting your solder will be relatively easy, and you will be able to work in a safe environment.

Accuracy, traceability and quality should always be your major concern when it comes to calibrating a soldering iron. You should always be committed to acquiring the right temperature to enhance your productivity.