The 3D printing process wouldn’t be complete without 3D printer filament. The printer filament refers to the thermoplastic feedstock for 3D printing. In the market, you can buy different filaments that have diverse properties. (The filament requires different temperatures in order for you to use a 3D printer.)

In this article, we’ll talk about how to reuse 3d printer filament. But first, here’s how 3D printing filament is made.

3D Printing Filament Production

Filament creation involves the process of extruding, heating, and cooling plastic materials to transform the nurdles into the finished model. These nurdles are always clear or white. Additives and other pigments are added to the nurdles in order to create a colored filament. (In most cases, the pigments increase the magnetic properties and strength of the plastic.)

The nurdles are heated in order to dry it and lessen water content. The nurdles should be dried because thermoplastics are hygroscopic. Also, damp plastic causes dimensional flaws that affect filament creation.

Then, the nurdles are put into the single screw extruder where it’s heated. The filament’s diameter is measured using a laser. (The laser makes sure that the filament has the right diameter.) Then, the filament is put into a warm tank that allows it to cool and give it a round shape. The filament goes into a cool water tank for it to cool. Last, the filament is wound to a spool, and then you’ll see the finished product.

DIY Filament Production

Do you want to make your own 3D printing filament? Well, you can use filament production machines that use a similar procedure as the FDM 3D printers. The DIY production machines push the filament to the extruder to make the correct filament diameter. DIY filament machines are available in the market if you want to buy a machine.

Here’s how the 3D printing filament is turned into a 3D model:

- Feed the filament to the 3D printer.

- You heat the thermoplastic inside the hot end.

- Now, the filament is extruded and deposited to a build platform where the filament cools.

- Repeat the first three steps to build layers until you create a 3D model.

Despite the effectiveness of 3D printing production, filament creation is a threat to planet Earth. Each year plastic waste continues to fill the waste bodies and landfills. Hence, the tons of waste give an ecological challenge to the planet.

In a year, thousands of marine creatures face plastic entanglement, while millions of others might succumb to plastic ingestion in the future.

Because of this scenario, 3D printing enthusiasts think of using green 3D printing. In this process, 3D printer filament and other materials are reduced, reused, and recycled. Green 3D printing is an effective way for manufacturers to control 3D printing wastes.

Note: 3D printing materials such as ABS and PLA take more than 500 years to decompose.

So, here’s the important question we need to answer – how to reuse 3d printer filament to control waste?

Thanks to advanced technology, we now have the following ways to reuse 3D printer filament.

The 3D Filament Recycler

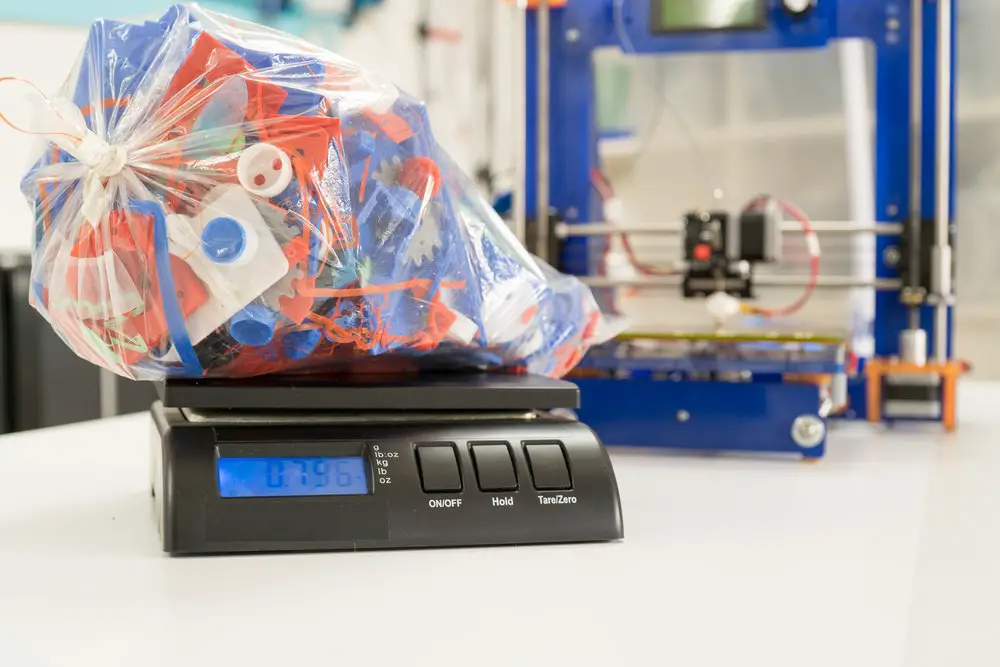

One of the best ways of reusing filament waste is using a 3D filament recycler. (You might have seen or bought one of these awesome machines in the market.) So, how does a recycler work?

The process of reusing or recycling 3D printer filament is easy. The recycler smashes failed prints turning these to smaller pieces. Then, the prints are melted down and put the liquid plastic to an opening. Last, the hot plastic is cooled down and coiled to the reel.

Helpful Tips in Using the 3D Filament Recycler

- Make sure that the plastic or filament is clean. Note: you can have excellent results if you’re using plastics that have a similar composition.

- Don’t mix different filaments because these could lead to poor printing results.

Take note: not all machines are capable of extruding and shredding. In this case, you need to buy two machines to reuse a filament.

Extrusion Process

The market offers you different extruders that you can use to recycle filament. You can buy DIY extruders or plug and play devices. Both these machines are reliable in filament recycling, depending on your preference.

Most extruders in the market are compatible with different polymers such as

- PLA

- ABS

- PVA

- PMMA

- PEEK

- TPE

- Nylon

- PE

Consumers like the easy and fast operation of 3D filament recyclers because of its features. Most recyclers have a touchscreen interface and extrusion settings. You can choose from affordable to expensive recyclers depending on your budget and, of course, needs.

But there are other recyclers that can shred and extrude filaments. These awesome 3D filament recyclers do shred and extrusion operation rather than a single device. You can reuse filament from small prints that you can use in the future.

A good example of recyclers that can shred and extrude filaments is the ProtoCycler. The recycler is invented by former classmates Alex Kay and David Joyce. Using this machine at home is more demanding than the traditional 3D printer.

Why?

Most consumers care about reusing filament wastes rather than throwing these. But make sure you have enough budget before you buy the recycler because these are quite expensive. If your aim is to conserve waste, the ProtoCycler or any similar machine is right for you.

Hire a 3D Filament Recycler Company

PLA and ABS materials are the most commonly used filaments but these aren’t recycled easily. But that’s not a problem if you have a 3D filament recycler company to help you. A recycler service helps you in recycling hard to recycle plastics such as ABS and PLA. Some companies encourage their clients to recycle filaments based on their programs.

One of these programs work by collecting used filaments and recycling these to become new filaments. You might even earn rewards if you collect scrap filaments regularly.

Hence, even If you have many filament wastes at home, you can still use these filaments. You choose the recycler machine you want and start the noble work of recycling wastes. Let’s continue saving planet Earth!