AC stands for air conditioning, and it often is overlooked by most people, thereby leading it to stop functioning altogether. Whenever you notice your AC compressor pulling out hot air during a hot day, it is highly likely it has a damaged component. Therefore, if your AC compressor is faulty, it is likely to cause engine failure because it is stuck, and your car can suddenly stop moving as you are driving.

This can subsequently cause an accident hence injury to you and other occupants. Furthermore, damage to the AC compressor typically causes a problem to the steering since the power will be limited, and your brakes are also prone to malfunctioning.

Therefore, it is clear that the AC compressor plays a crucial role in generating fresh air and consequently ensuring it circulates through the entire AC unit. If your car’s AC is not working effectively, you then are likely to experience a which might affect your overall driving experience.

Fortunately, a faulty AC compressor can be fixed, and all you need to do is do a series of tests on it to examine using a multimeter to realize where exactly the problem might be. After identifying the problem, schedule an appointment with an AX compressor expert or a mechanic to have the issue fixed properly.

Steps for testing an AC compressor with a multimeter.

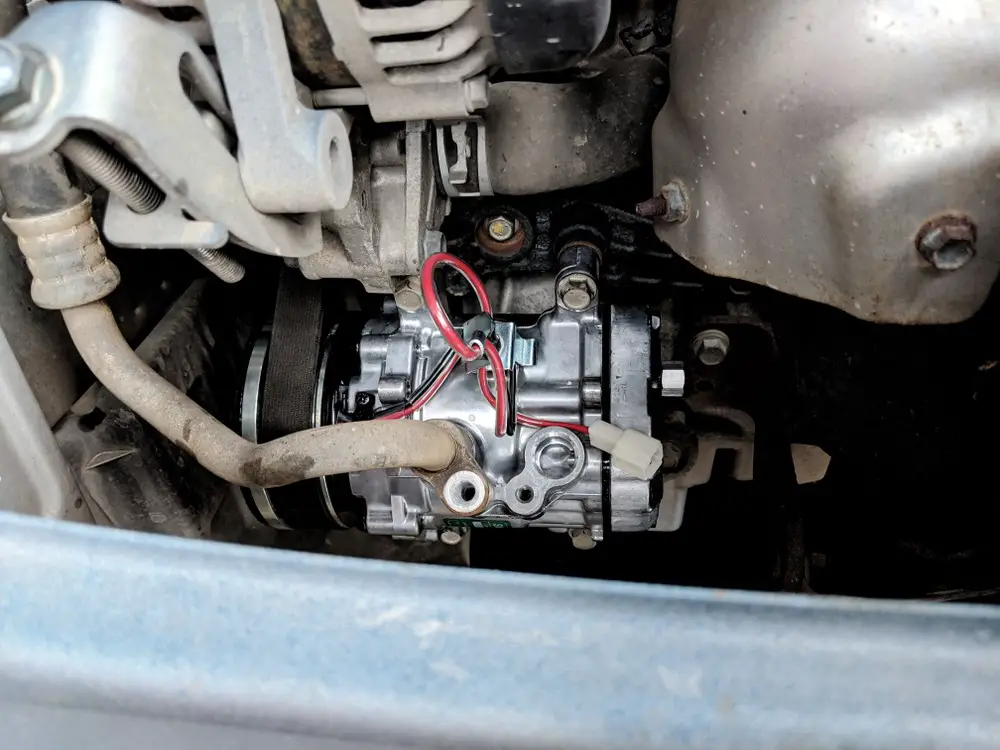

Step 1 – Inspect the AC compressor for any damage

Before you even start to examine your AC compressor, you should make sure that the energy circuit for your conditioning unit is switched off completely. Doing this is vital and will prevent you from getting electrocuted when testing the compressor. Thus, make it a habit to switch off the power circuit of your ac compressor and any other switch around it.

Afterward, do away with faceplates by unscrewing them your AC unit, and this will enable you to come in touch with internal elements, especially the ventilation holes and many other internal components. Once you are done, you should now remove the power access panel to examine how the wires have been connected to the AC compressor unit. Furthermore, you should check for burnt or terminals too within the system.

Step 2 – Examine for energy and ground at the AC compressor’s clutch

Make sure you disconnect your power connectors from the clutch compressor and have your multimeter set on direct current (DC). On one of the terminals, connect the positive probe leads in your clutch energy port and then connect the negative probe leads to the battery ground, set your AC, and then start your engine.

Observe the voltage being displayed on the multimeter; in case it is zero; you will need to move your positive probe lead to another terminal in your power connector. If the reading value displayed is still zero this time, move your negative probe lead to a different terminal.

Once you have both of your probes leads placed on the power connectors, this is a confirmation that both the ground as well as compressors’ clutch are getting adequate power supply; hence the clutch coil is the damaged component that needs replacement. Usually, come some clutches can be fixed, while others typically need to be replaced.

Step 3 – Check why there is no power supply on your compressors’ clutch

On the negative terminal of your battery, connect your negative multimeter probe lead to determine whether there is any flow of power on terminal 2 as well as 3. In case there is no voltage being displayed on your multimeter, inspect the wiring and fuses to the relay.

If there is power, place the positive probe lead on terminal four and the negative probe lead on terminal three, and you see it displayed on your multimeter the battery’s voltage. If there is no reading, consider your PCM to have an issue and not being able to generate ground to your control relay coil.

Step 4 – Examine no ground at the relay coil.

If the refrigerant system is low or the pressure in it is on its maximum level because your condenser is blocked or your TMX valve and orifice are faulty, you then should consider your PCM not to be generating ground to your compressor relay coil. Therefore, you will have to try and find them both, that is, the maximum, as well as a minimum pressure switch, and then connect both the negative as well as the positive probe, leads to the appropriate terminals.

Subsequently, start your car’s engine and turn your AC to its maximum as you examine the voltage that is being displayed on your multimeter on one of the terminals. If there is voltage, this means your PCM is generating energy, and should thus perform an identical test on switch 5. In case there is power on all switches, then you require performing a continuity test across all the switches.

Step 5 – Inspect for continuity at the pressure switches

Set your multimeter on ohms, and then place one meter lead to a particular terminal (5) located on the low-pressure switch while connecting the other to the terminal (7) on the switch. When the switch is shut, it means your refrigerant is proper, and you will have the reading displayed, but in case your pressure is extremely low. The switch will be opened, and you will most likely get inaccurate reading values between terminal 5 and 7.

Perform the same procedure on the maximum pressure switch, with your multimeter set on ohms. On the maximum pressure switch have one of your multimeter probes leads connected to your terminal 8 whereas another one to terminal 6.

If the switch is closed, you should then consider that the pressure of your refrigerant perfect since the reading value will be displayed on your multimeter. In case the pressure is too high, then the switch will be open, and the reading value shown will be infinite around 5 as well as 7. This means you have a severe problem in your ac compressor that needs to be fixed by an expert.

Conclusion

Based on the above information, you should now know how to test your AC compressor with a multimeter. Usually, this is only the only essential tool you need during this test, thereby showing its overall importance. After the test, you will be in a better position to tell whether or not you need to have your AC compressor replaced or repaired.