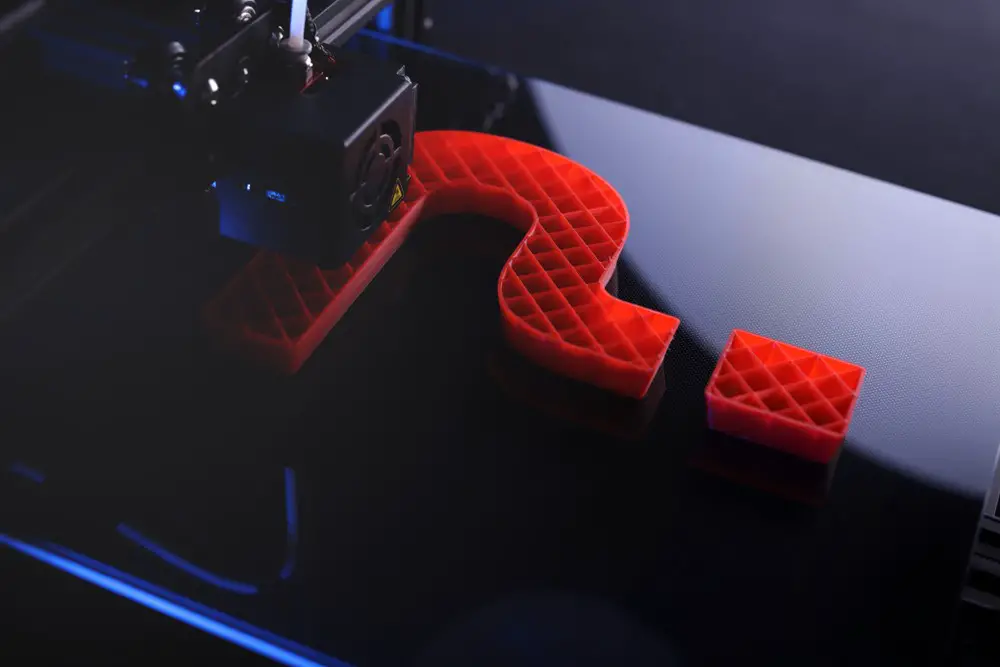

If you are asking yourself about “what does a heated bed do on a 3D printer?” The first thing that you should do is to know what a heated printer bed is.

When we say a heated printer bed, it talks about the additional module that is being placed under a 3D printer. The main work of the heat bed is to provide a better and more controlled result from the 3D-printed objects cooling process.

Heated Printer Bed – How is It Used?

The heat beds are also being used in preventing printer problems, such as thermal warping and runaway, poor adhesion between layers, and poor adhesion in the printing bed. The heated bed will make a lesser waste and excellent precision. It is because of the fact that it prevents the uneven or early cooling of the printer.

The presence of the heat beds under your 3D printer will provide you with suitable conditions, which are ideal for producing an excellent printing outcome. This is always true when the local conditions are colder or are not being appropriately controlled. The heat beds are the primary item that you must have. This is always important when you work with ABS plastic and other similar materials.

Usually, the heart beds are partially constructed for the users. These items have been designed for the use of local 3D printers. But there are some printers that are now available on the market that feature an enabled-heat bed in it.

The heat beds can be constructed with the use of PCB or the Printed Circuit Board that comes up with heat spreaders and heat designs. These heat spreaders might be made up of silicon, or even aluminum. The heat on the heat beds is being regulated with the use of a thermistor.

The thermistor will help you to adjust the heat to your preferred temperature. Generally, the starters and the expert users of the heat beds usually use a temperature of 70 degrees.

If you want to have a higher level of heat, you must have a .04 to .07 cm or watt as the power level of your heat bed. This is always true when you want to start your printing process with the use of faster and higher heating. You can calculate the power requirements depending upon the print bed’s size.

The heat beds are being placed on the area wherein the printer head is printing its media. If you want to remove the parts easily and more conveniently, make sure that the heat spreading area is being surrounded by a Kapton tape or even a simple painter’s tape.

Why Should You Use a Heat Bed?

There are numerous reasons that you might consider why you should use a heated bed while performing the 3D printing process. One of these reasons is that the heat bed is being used in improving the quality of your printed models. This is because the heat maintains the warmness of the plastic materials. As a result, it will avoid warping.

When we say warping, we refer to a problem that is resulted from the cooling down of the plastic materials. In connection to that, the temperature of the plastic materials is different from the materials inside located inside. Since then, the plastic materials will start to warm up and deform your object.

What are the Different Types of Heat Beds?

In spite of the type of heat bed you are currently using, it is a must for you to follow the required temperature, especially if you are using ABS or PLA materials. For PLA materials, the required temperature is 50 degrees Celsius to 60 degrees Celsius. On the other hand, the required temperature for ABS materials is 100 degrees Celsius to 110 degrees Celsius.

Kapton (Polyamide) Film Heater

The polyamide or Kapton is known as the best choice for tape when it comes to printing surfaces. It is mainly because of the fact that it will provide you with a higher adhesion level for PLA materials, smooth finish, and higher heat resistance.

Generally, the Kapton or Polyimide film heater is thin. It only means that you can install it easily with the use of an adhesive. As a result, you can now have a reliable and faster heat for your printing processes. Aside from that, it also features a built-in thermistor that comes up with a wide range of shapes.

PCB Heat Bed

The PCB heat beds are the ones that are commonly used by those who are using 3D printers. It is because you can purchase it at a lower price rate and provide you with excellent work. The PCB heat Bed comes up with two enabled LEDs and resistors.

You can install this heated bed cleanly, simply, and easily. This can be done with the use of its 5 holes that are mainly used for installing and leveling uses. The only drawback that you might notice with this heated bed is that it produces heat slowly. This is always true when you use to attach it to different areas, including the glass pane surface.

Aluminum Clad Heaters

The aluminum-clad heaters are considered to be an inexpensive and efficient heat bed. But, take note that the installation of this heated bed will require more steps. As a result, it might take some time to install it. In fact, you are required to screw it on an aluminum plate or stainless steel.

Aside from that, it must have a complete electrical circuit that comes up with an insulator or a thermistor. On top of that, it would be a great idea if you are going to utilize a thermal paste that is placed in between the heated surface and the clad heater.

Conclusion

To sum it up, there are two things that you should keep in mind with regards to the heat beds use. The first one is that it helps in increasing the energy of the surface to maximize the first layer bonding strength. Second, it will offer a free from warp foundation for your entire printing experience.