A crimping tool is a gadget that is used to create a joint either between two metal pieces or any other material with excellent malleability. To conjoin these metal pieces together, this device deforms both or one of them, thereby creating a rigid joint to hold them together. Attaching a connector to a cable’s end is an excellent example of the crimping process. The joint formed by the crimping tool is robust enough to ensure all applications run smoothly.

Check Out: 5 Great Hydraulic Crimper Recommendations

Moreover, crimping tools, also referred to as as crimping pliers or crimpers, come in different designs as well as several sizes depending on the function it is expected to perform. Before selecting the ideal crimping tool, there are several differences in purpose and function that you need first to consider. In the communications and electrical industries, you will find a wide variety of crimping operations because of the many connectors used on wires.

Crimping Tool Uses

Some of the applications which need crimping include wired mesh connections, bullets, and coax cable connector assemblies. With a crimper, you clamp the metal to a substrate, and by placing sufficient pressure, the metal is subsequently deformed to the point where you can fasten it securely.

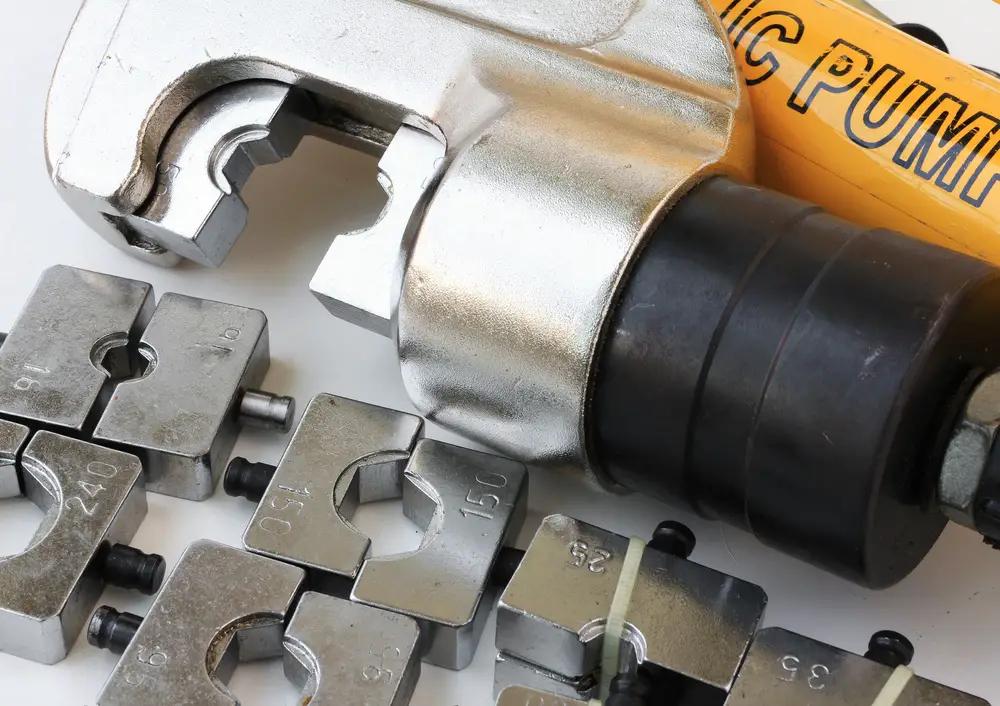

The kinds of differences in crimping tools includes the dimensions of the handgrip, the clamping jaws, the clipper capabilities as well as materials of the crimping tool. Moreover, other crimpers are multifunctional tools, thus have additional features like wire shredders and cutters, features that complement the normal crimping needs. Whereas most of the crimping tools are manual, there exist, hydraulic crimping pliers, which are ideal if you want to carry out numerous crimps in a day or apply additional force.

Different types of crimping tools

Crimping to wires

Because most crimping applications entail joining together wires and metal connectors like the coax connector assemblies, crimping tools typically are rated established on the American wire gauge (AWG). This rating is usually the standardized wire diameters that are used in determining the wire sizes, and it ranks the wires in an ascending numerical system. This means the higher the AWG rating, the smaller the diameter; thus, wires with huge diameters are denoted using a series of zeros like 0000, and the least is 50 for a very tiny wire.

Additionally, some crimpers have a predetermined crimped shaped, and these are known as “died crimpers” because their jaw sizes come in fixed die sizes. Most crimping tools are usually designed to be useful for several wire sizes ranging between four to eight to make them appropriate for numerous projects. There also some more sophisticated crimpers that can handle over ten gauge sizes, so it is up to you to find one that handles all the wire gauges you require appropriately.

The dyeless crimping tool is also another common variety and is more often used for general use crimping tasks since they do not have any predetermined shape.

Handheld crimpers

Handheld crimping tools are very common. Therefore, you should find a crimper that has an ergonomic design as well as soft handles, especially for jobs that need a lot of crimping operations. Furthermore, some crimping operations require plenty of force, for instance, crimping a hard metal such as steel needs the use of a crimper with steel handles to prevent it from snapping when it is being used.

However, for lesser level operations that involve plastic crimping jobs or softer metals, you should get yourself plastic crimper handles.

You can also find spring-loaded crimping tools, and these are effective for carrying out crimping tasks that need little preparation and are numerous as the spring aids in speeding up performance. Therefore, you are not required to use a spring-loaded crimper when carrying out tasks that need focus and precision. Nevertheless, you can still use this tool if you wish too.

Additional pressure for crimping applications

If you are performing tasks that need precision and lots of pressure, a ratchet crimper would be a perfect choice. The ratchets enable the crimper’s jaws to be positioned more accurately, thereby reducing the likelihood of any human error when constricting the teeth. Ratchet crimpers are useful in Datacom operations since these tasks usually entail crimping a connector through several wires instead of a single wire. However, if you are performing simple single-wire crimping tasks, then you can use a standard crimp joint.

A hydraulic crimping tool is perfect if you are doing heavier jobs which entail lots of crimping operations, or you often handle harder metals that do not deform easily. Crimping usually requires you to place a lot of pressure on the crimping tool, and repeating this action numerous times may cause your hands discomfort and stress, which, if overlooked, can cause severe injury. Fortunately, a hydraulic crimper does the role of a crimp effectively, quickly and mechanically hence requiring little effort from you.

Nevertheless, hydraulic crimpers, in comparison to manual crimpers, are very expensive and only recommendable if you are doing jobs that need more than 200 crimps daily. Furthermore, they usually are either remote-hydraulic or hand-hydraulic, plus there also is battery actuated crimpers that offer you a broad range of pressures but at a lower price compared to hydraulic crimpers.

Alternative Crimping Tools Styles

Included in this category are hammer style crimping tools that typically look like the microscope stand. Additionally, these crimping tools, unlike handheld crimpers, are more durable and can apply more pressure hence not advisable for delicate and small jobs since they destroy the substrate. You can find a hammer-style crimper both in hydraulic and manual versions.

How does a crimping tool work?

Before you use a crimper, you first need to place a wire into the connector. Confirm you have put all the wires in the jack, and then place the connector with the wires into the crimper, followed by squeezing the handles together. The plastic connector gets punctured by crimping and holds every wire, thereby allowing the transmission of data through the connector.

Factors to consider when looking for a crimping tool

Ergonomic design

You need to consider how comfortable it is to use a crimping tool is on your hands before making a purchase. Handheld crimpers with an ergonomic design guarantee your hands will never get tired. Consequently, you will be able to ensure your hands are free of stress as well as maintain a steady grip on the crimper.

Price

Crimping tools come at different prices, but the more you invest in a quality pair of crimpers, the improved the performance. Therefore, if you want a crimper that provides you with exceptional performance and is long-lasting, then you should opt for a well-known brand. With crimping tools generally not expensive, investing a few additional dollars is something you will not regret.

Warranty

When searching for a high-quality crimper, you should carefully inspect the warranty information. If the crimping tool does have a warranty, you should find out more about the terms and conditions. Whereas you probably will never use it, knowing the company making the crimping tool provides you with a warranty helps you have peace of mind.

Volume

It is crucial you first asses the volume of your tasks before deciding which crimping tool you need to buy. If you often use a crimping tool, you should opt for automatic toolings such as a hydraulic model or pneumatic press. However, if you occasionally carry out crimping duties like those in a repair shop, you should opt for a multi-purpose unit that is affordable as it offers you more value.

Use of the crimping tool

When looking for the best crimper, you first need to understand what are your needs as this will enable you to make an informed decision. Some of the questions you need to ask yourself include what the crimper can do, that is, can it cut and join connectors to numerous cables, can it strip, or can it be used to connect pipes when doing plumbing operations.

If you often work with electronics, network cables, plumbing, or computers, you need to always have a reliable crimper at your disposal throughout your career. Moreover, as a homeowner, this tool helps you perform various household tasks effortlessly.

Crimp size

Crimpers come in various slot sizes, thereby enabling you to do several crimping duties. The most common crimping positions service sizes are 4, 6, and 8 position modular connectors. Additionally, other common crimping tools covering a wider range of sizes are RJ45, RJ12 as well as RJ11.

Related: Good Crimpers Recommended for You

Wire gauges reach 50, and this is the small wire size. Usually, the less this number gets, the bigger the size of the wire. Thus, you should go for a crimping tool that works a broad range since it offers you more versatility, unlike a single-size crimper.

Blade Guard

When searching for a crimper, you need to buy one that features a proper blade guard to safeguard you do not injure yourself accidentally. This is the most secure and safest way to protect yourself while stripping wires, so it is an investment you will never regret.

Conclusion

Having read this article, you know have a clear idea of what is a crimping tool. Furthermore, you know its use, the different types of crimpers as well as what to consider when looking for one. Therefore, you are now better placed to know which crimping tool you should buy to meet your needs. Consequently, you will be able to perform your duties efficiently and quickly.