The wattage of a soldering iron determines how fast the tip heats up. Thus, irons with a high wattage heat up faster and make it easy to maintain a high temperature. Soldering involves transferring heat from the tip to the solder joint hence the need to look for a device that heats up fast and transfers the heat rapidly.

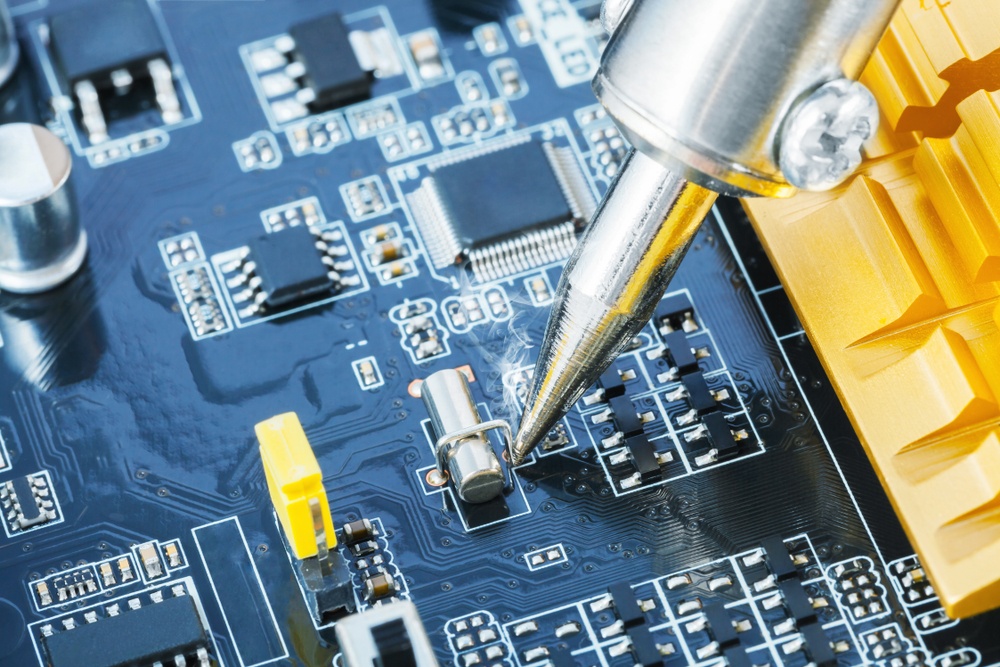

Note that the wattage of soldering iron should not be considered in isolation. The size of the tip plays a significant role too. For example, when soldering delicate surface mount components, you need soldering iron with a thin tip and a lower wattage to avoid damaging the parts.

However, when soldering large joints, e.g., a connector, you need to use an iron with a thick tip and a higher wattage. So how do you know what wattage you need for your soldering applications?

Do High Wattage Irons Produce More Heat?

Most soldering irons used for electronic applications have a wattage of 20-60 Watts. Irons with an average of 50 W, for example, produce adequate heat for soldering circuit boards. It does not mean irons with a high wattage produce more heat; on the contrary, they just have more power available.

Soldering irons used for large-scale production involves working on many joints per hour. As such, the user has to use a tip that retains the operating temperature or resumes the original temperature quickly.

Traditional soldering irons required users to set the highest temperatures to ensure the tip maintained the operating temperature. This notion is true to some extent, but it presented a few challenges:

- The high wattage damaged electric components and caused the tips to wear out fast

- The high wattage translated into higher energy bills

Modern soldering irons have been upgraded, now able to hold and resume the original operating temperature quickly without consuming too much power. Three features make it possible:

- An improved tip design: Copper/iron alloy is used to make the tips, and it is known as a good conductor of heat

- Improved control circuit design: Soldering irons now use zero-crossing control circuits that regulate the power of a heater. The feature also keeps the iron on when required to solder components and off when not. Newer soldering irons are fitted with a microprocessor that fine-tunes the device to an idle setting and a short recovery time of about a tenth of a second.

- Upgraded sensor: The sensor is part of the control circuit. Modern irons are fitted with more accurate sensors, responding to changes in temperature quickly

As such, with modern soldering irons, it is not about power output (wattage) but the ability to control the temperature. All you need is adequate power to keep the tip hot.

Do You Need Low Wattage Soldering Irons?

Yes. As earlier highlighted, low-wattage irons are ideal for small soldering jobs. The only downside is that a 15-watt iron, for example, delivers 15 watts to the tip. As such, the tip temperature stops increasing once it attains an output of 15 watts.

Also, low wattage irons lose heat rapidly once they touch the component. What’s more, if the part being soldered dissipates enough heat, then the temperature keeps on dropping until it can’t melt solder. The temperature rises, once the iron is pulled away. Thus, low-wattage soldering irons are ideal for small tasks, e.g., soldering small resistors.

Larger components,e.g., voltage regulators, you need more heat to absorb and dissipate. As such, a 25 or 30-watt soldering iron should do. Other larger items like heat sinks, motor casing, or 10-gauge copper wires need soldering irons with an output of 50 watts and above.

Tip Size and Wattage

The tip empties its heat once it touches a component faster than the iron can replace it. As such, smaller tips dissipate heat faster, causing the temperature to drop to an ineffective level. Users have to wait in between joints for the tip to resume its operating temperature.

Larger tips, however, can hold heat for a more extended period, even with a small wattage. The length of the tip may need to be minimized to enable them to maneuver tight places where longer tips are required. Also, irons with large tips take more time to transfer heat through the tip.