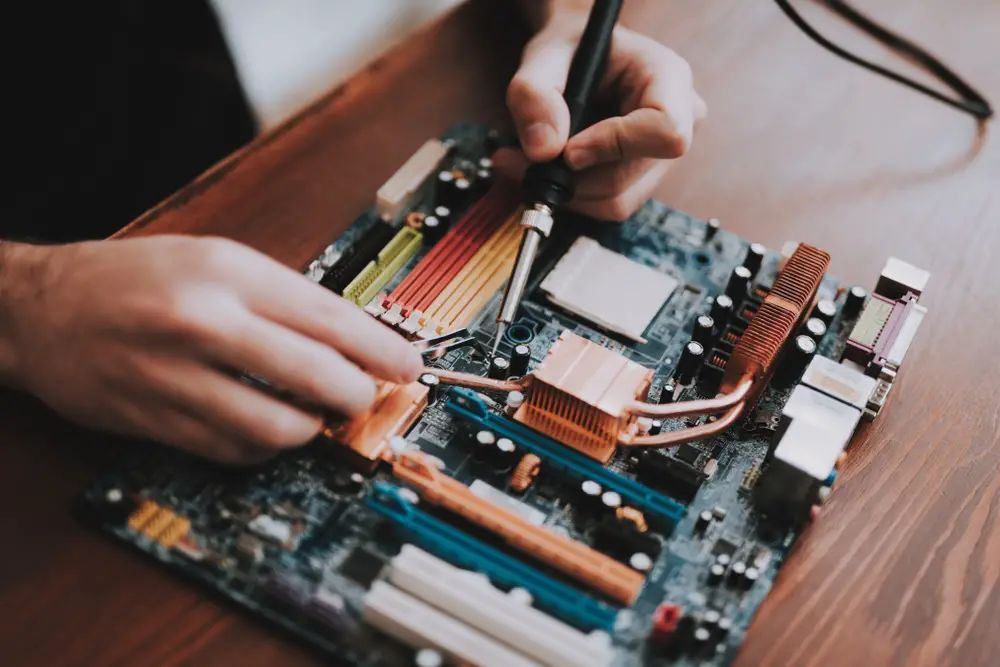

A soldering iron is the most critical tool when working on printed circuits and electronics. The irons produce different wattages hence the need to look for one that suits your soldering needs. Using equipment with extremely high or low wattage can damage the board.

A wattage of 15-30W is recommended for basic soldering on delicate electronic boards. However when working on complex components like the Pentium motherboards you need a more powerful soldering iron.

Earlier on, desoldering of capacitors on PSU and networking equipment was pretty easy as it require soldering irons of minimum power. More recent versions, (Pentium 4 and above) have large ground planes which draw out heat from the components you are desoldering. Additionally, they are attached to the boards using lead-free solder and other types of production-grade solder which does not melt quickly when soldered.

Ideal Wattage for Soldering Motherboards

As such, when working on this equipment, you need to desolder the capacitors at high heat then solder the components back. If the iron does not produce adequate heat, it prolongs the heating period and might damage the thru-hole. What’s more traces may get lifted from the motherboard. Using a soldering iron with adjustable wattage helps maintain the appropriate temperature for the job.

The ideal temperature for working on motherboards is 40W. 60-80W irons are suitable for heavy duty applications on larger motherboards. Other features like the design of the tip and the quality of the soldering iron also determine whether the soldering iron will perform well with regard to the wattage.

Other Considerations

Digital vs. Analog Soldering Station

You want a long-lasting soldering iron if you are planning to execute a range of soldering jobs. Digital irons are excellent if you are working on soldering temperature sensitive boards, e.g., those that need an exact temperature.

Analog irons and stations, on the other hand, are suitable for capacity replacement. They allow you to set a high temperature to desolder components and a lower setting for attaching new capacitors.

Type of Soldering Iron

The type of iron affects the wattage it can produce to work on an electronic board. Soldering irons and soldering guns are particularly useful when working on motherboards.

High wattage irons (can produce 40w and higher), for example, are ideal for working on thick wires and other heavy components. Also, soldering irons have a pinpoint heat source suitable for precise heating as that required on motherboards.

Soldering guns, on the other, hand can produce high wattages as the electric current flows directly from the tool. However, they are not ideal for soldering jobs that need precision.

Construction of the Soldering Iron

Soldering irons made of 50% tin, and 50% lead can produce a temperature of 425 degrees Fahrenheit. However, those made of 60% tin and 40% lead will deliver a lower temperature, i.e. 371 degrees Fahrenheit.

Another with a higher composition of tin (63%) and 37% of lead produce an even lower melting temperature reaching up to 361 degrees Fahrenheit. It is important to check the specifications of the soldering iron you want to ensure it delivers the required heat for working on the motherboard.

Antistatic Feature

Expensive soldering stations have an antistatic feature usually according to military standards. While this is not a requirement for working on computer equipment, it is an essential feature when handling the iron.

You also need to consider if the iron has an on and off switch or uses a high-frequency effect. Experts recommend using a grounded soldering iron to avoid damaging ESD-sensitive parts.

Temperature

The soldering iron should have at least a temperature of 200-450 degrees Celsius. This range is ideal for desoldering capacitors and fitting new ones.

Corded vs cordless Iron

Cordless irons are suitable for technicians looking for a more portable option. They are however not as great when it comes to adjusting the temperature. Corded soldering irons are ideal especially if they have allow you to adjust the temperature.

Cold-heat Type Models

These kinds of soldering irons are not suitable for working on electronics, especially if working on motherboards. This is because they produce high amperage current at the tip when soldering which can damage capacitors and other components. They also produce sparks. Additionally, the manufacturer prohibits the use of the tools on electronics.