When you leave your gas tank outside exposed to weather elements for an extended period, gas will start leaking due to corrosion that created a hole. Repairing your gas tank will require time, effort, and incredible soldering skills.

When it comes to soldering gas tanks, you should always put safety as your top priority since it is highly flammable. However, the soldering process is relatively easy and can be mastered by anyone within a few minutes. Therefore, as we take you through the process of repairing a gas tank in this article, we shall be answering the question; will a soldering iron ignite gas?

Soldering A Gasoline Tank

When it comes to soldering a gasoline tank, safety should be your major concern. However, the best part of working with a soldering iron is that it will not create any spark; this means that there is a minimal chance that it can ignite the gas. Nevertheless, it would be best if you always took precautions since nothing is impossible. When soldering your gasoline tank, you will need to factor the following vital aspects:

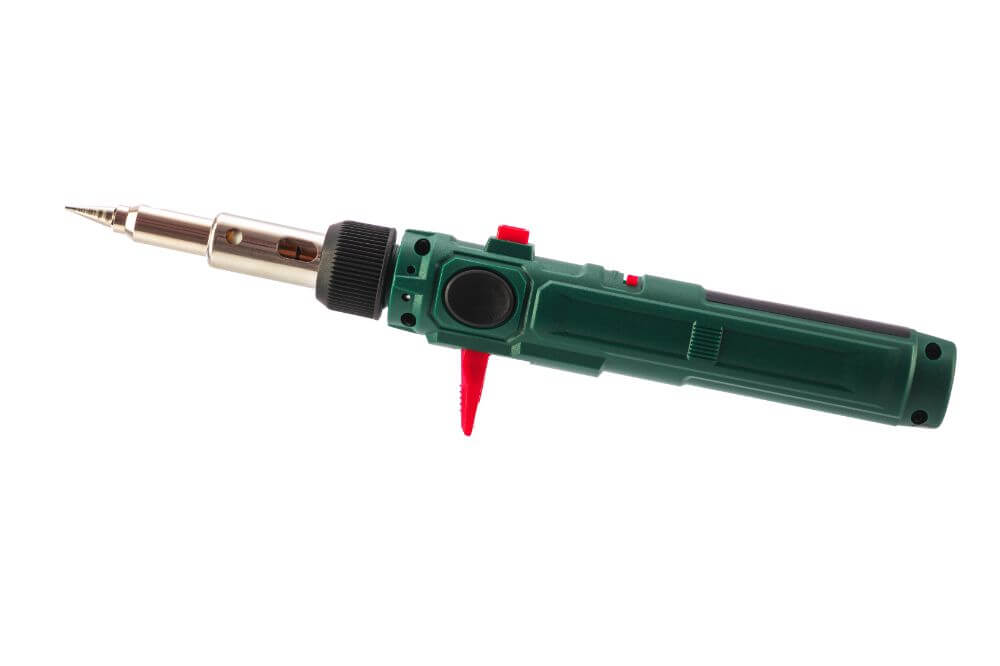

Soldering iron

It would be best if you considered working the right soldering iron tool for this particular work. A soldering iron for wiring repair should feature an output of approximately 20 to 30 watts. However, it is highly advisable to have a 100 to 200-watt sheet metal solder soldering. This is said to be vital since most gas tanks are equipped with a thick iron plate that requires a bigger wattage.

Draining your gasoline

Before commencing on soldering, you should first drain your gas tank and dry its inside. Since most fuel tanks are made of steel plates, you should consider using solder for sheet metal. Furthermore, it would be best if you considered using a special flux (HCL) to help in treating the iron plate surface effectively.

In addition to hydrochloric acid, you might as well consider using a gas burner to help in getting rid of the paint and heat efficiently the area that needs repair. When you start repairing your gas tank, you need to ensure that the gasoline, along with any other flammable gas, has been drained completely. It is best if you prepare in advance.

Wash the gasoline tank

Once you drain your gasoline from the tank, you should consider cleaning it with water before you start soldering. To dry the inside of your gasoline tank, you will need to pour some amount of neutral detergent and slowly pour tap water to help wash the inside of your tank. When the tank is filled with tap water, the flammable gas present in the tank will be displaced. In addition to this, you should as well consider getting rid of rust present in the tank.

You can assess for drops of water from the point where the paint is burned off from the tank using the torch. The rust within the leakage area can be removed easily using a wire brush and then apply flux on the affected area and the surroundings.

Soldering

Once you coat, film, as well as dirt around the leaking areas will be removed smoothly and then apply flux and then start soldering your gasoline tank. After soldering the affected area, you should consider flushing it using hot water and then polish it with a stainless steel brush to help in getting rid of the flux. This process is vital, and it helps protect the tank against the recurrence of rust.

Always remember to:

- Get rid of the paint on an iron plate and then polish the area affected using a brush wire once the surface of your metal is exposed.

- Apply special flux for the sheet metal on the affected area along with its surrounding.

- Use a brush to apply flux cleanly and avoid wastage.

- Warm the affected area using a soldering iron. Once that is done, you will melt the solder and then run it through the affected area.

- In case the base material is not heated accordingly, the solder will not melt and run into it. On the other hand, when it is overheated, the solder will become round as a result of surface tension preventing it from running as well. This means that you need to heat the base area using a well-balanced temperature.

- When the heat is lost due to additional heat when using a soldering iron alone due to the iron plate’s thickness, you might consider using a gas burner for enhanced effectiveness. You might as well consider using an industrial heat gun and heat the affected area and offer to warm back up.

Point To Note

- When your solder melts and runs smoothly into the tank’s affected area, the solder will start piling up on the affected area.

- However, when the solder is not piling up, you should consider brushing the affected area using a stainless steel wire brush to get rid of any dirt present. Once that is done, you will reapply your flux and then start the whole process once again.

The process will then become successful if the solder melts and piles up on the affected area.

Final Thoughts

When hearing about soldering repair, most individuals tend to think it is all about electrical wiring; however, this is not the truth. Soldering is used in numerous applications with repairing your gas tank being one of them. If you are a do-it-yourself enthusiast, soldering iron will be a vital tool for your everyday projects.

When mastered accordingly, soldering skills are vital and helps in repairing and coming up with various unique projects. With a soldering iron, all that is required of you is to be creative, and you will be able to design and repair almost anything.

Solder cannot ignite a gas; however, since the soldering process involves heating your solder and melting it, you should consider keeping the above tip in mind. To enhance your safety, always drain gasoline from the gasoline tank before you begin the soldering process. As we conclude, we hope that this article has been helpful.