Are you ready to learn? We will show you how to make a mini battery-powered soldering iron tool. The advantage is; you get to save a lot of money because the materials are not expensive to buy. You will notice that the instructions are easy to follow and do not require too much time.

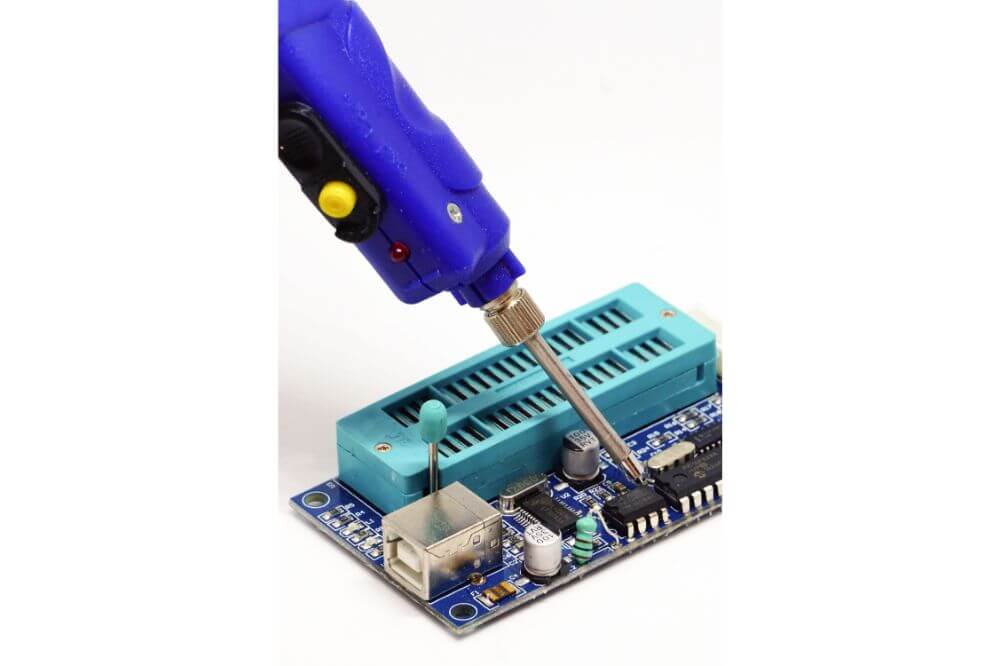

The final result will be a portable battery-powered soldering iron. You can use it anywhere you choose. It is also small enough to take care of tasks that require little space.

The charge of the batteries should give you sufficient usage to take care of your soldering tasks. It is important to note that battery-powered soldering iron tools are excellent for jobs that do not require too much time. The weight can be inconvenient if you’re looking for something to use daily.

If you are a light user, it only makes sense to teach yourself how to make your soldering iron. Why spend hundreds of dollars on something you can put together quickly and cheaply.

So, let’s get into the steps you will need to take when making a mini battery-powered soldering iron tool.

Materials You Will Need for the Project

Head over to your local hardware store and stock up on the following:

- 50 mm long copper wire with a diameter of about five millimeters

- 30 by 50 mm copper coil

- 400 mm long nichrome wire with a diameter of 0.2 mm. You can buy or source it from some of the items within the home. Most of the appliances that heat up will have nichrome wire in them. Such include hairdryers, kettle, or curling irons.

- Insulation tape

- Metal tube for the heater

- Silica glue

- Talc powder

- 2, 1.5V AA batteries

The battery-powered soldering iron should give you between 25 to 40 Watts of power. You will find that it can easily melt most of the solder. If you are repairing microcircuits, semiconductors, or even SMD components; it will become an invaluable part of your tool kit.

Let’s dive into the assembly.

Sketch the Design

Having an idea of what kind of battery-powered soldering iron design you want will make the process smoother. Sketch your idea on a piece of paper and use it as a guide.

If you’re not very good at sketching, download pictures from the internet. Just ensure they best represent the ideas you have in mind for your mini battery-powered soldering iron.

Making the Tip

To make the tip, you will need a copper wire, which will be the primary material for the sting. Sharpen one of the ends to resemble a screwdriver.

Think about your future soldering projects to determine how wide the sting should be. Ideally, anything between 2 to 5 millimeters should be sufficient.

Making the Heater and Insulation

- You will need to mount the heating element on the sting. You must, therefore, prepare the surface appropriately. A mixture of talc and silicate glue should work quite well. It will provide the insulating layer you need.

- Let the application dry first before moving on to the next step.

- Wind copper foil to form a tube on the tip where you allow for a protrusion of 10 millimeters or less from the top.

- Now put another layer of insulation on top of what you have just covered. Allow it sufficient time to dry. Do not try and speed up the drying process by putting it over a fire. You may, however, use a hair dryer blowing on gentle heat if the rule temperature is not conducive to quick drying.

- Leave the two ends free at approximately 30mm and 60 mm, respectively, and wind the nichrome wire on top of the insulation.

- Cover everything in the insulating mix and wait for it to dry.

- Now bring out your insulating tapes, because you need to prepare for the battery connection. You will be connecting the nichrome thread to the batteries using copper wires. Ensure that you insulate the copper wires first.

The switch and casing

- Any plastic tube with a diameter of 18 to 20 millimeters should work well for the casing. You can, for example, use a medical syringe. Just ensure you remove the unnecessary bits like the sides, ears, and lower parts. What you opt for should have sufficient space for the wires and batteries.

- Strips of tin are excellent for making the contact plates. Insulate them; only leaving the areas that are important for making a connection.

- You must also leave a gap on the supply wires where you will connect a switch.

Your assembly is complete, and you should have a functioning battery-powered soldering iron.

What if it doesn’t Work?

Despite your best efforts, you may find that your soldering iron is not working the way you thought it would. You may need to troubleshoot so that you address the issues. So, look out for the following:

- If the soldering iron only gets warm but not hot, you may need to change the batteries. It is a good idea to buy rechargeable ones so that you do not keep on replacing the ones that have run out of juice.

- If the iron does not get hot at all, there could be a problem with your connection. As frustrating as it can be, you may need to recheck everything.

- Your batteries seem to be heating up while the tip remains cool. There could be a short in the battery connection. Immediately you notice the heating, remove the batteries. Insulate the connections so that the two leads do not touch.

Final thoughts

We have gone into a detailed exploration of how to make a mini battery-powered soldering iron tool. All you need is the right material, a tutorial such as this one, and sufficient time allocation to complete the project.

While it may not end up being as pretty as those you would buy in a store, there is something immensely satisfying about DIY projects; you get to save a lot of money, and it feels great to work with your own creation.

Most importantly, if you followed the steps correctly, you will have a functional soldering iron, which is what you need.