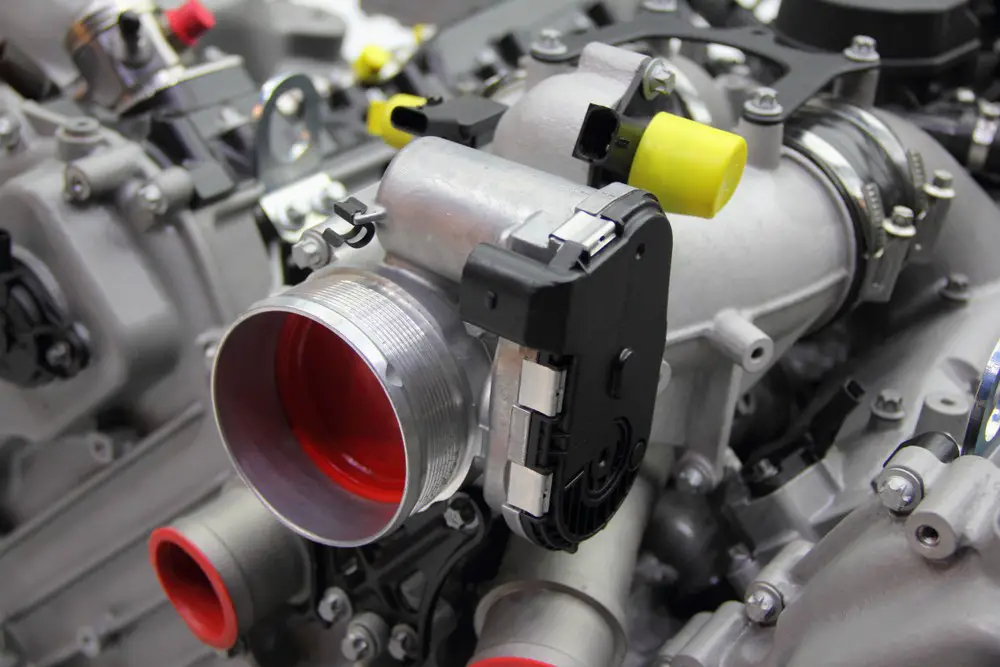

The throttle position sensor is a power resistor located on the throttle body, and it carries out the function it has the purpose of feeding data to your engine control unit despite the level at which the throttle valve is open. Therefore, it is clear that it is essential always to examine the throttle position sensor to confirm that it is still functioning correctly or whether it is faulty.

Usually, whenever there is an issue with the throttle position sensor, you are likely to have a problem with how your engine functions. This is vital since the sensor does the role of giving feedback to your electronic controller unit (ECU), which is also crucial for managing fuel delivery and managing the auto transmission shift controller.

TPS Issues

So what are the signs of a faulty throttle position sensor? Well, here are some of the clear signs that the throttle position sensor needs to be inspected;

- Poor acceleration

- Poor engine performance

- Fire breakout on your engine

- Sudden transmission shift

- Gas leakage from the exhaust pipe

- Overdrive loss

The primary function of the throttle position sensor is to monitor how the throttle is positioned as well as the amount of air making its way to the engine at any particular time. Therefore, the throttles’ body does the function of managing the air that makes its way to the engine. So, when the accelerator is pushed down, the entire body of the throttle opens up widely to let in enough air. By following the above criteria, the electronic control unit can calculate the amount of fuel needed to match the quantity of air, making its way to the engine as well as making adjustments to the fuel output resulting from your injector.

Examining the throttle position sensor with a multimeter

Testing your throttle sensor with a multimeter only requires you to have some basic knowledge as well as necessary skills along with a user manual that you can refer to in case you experience any difficulty. All the tools you need to examine the throttle position sensor are;

- Digital multimeter

- Magnifying glass

- OBD2 code reader

With the tools in place, you can go forward and test the throttle position sensor.

Step 1: Check the code reader

As you carry out this procedure, you need to acquire the OBD2 CODE reader, as this tool will allow you to tell the DTC that is present in the memory of the ECU. This is achievable only when you make sure that your code reader is well-connected, and after that, you can turn on the ignition key. Once you find out the codes in the memory, make sure you have them cleared up and have your OBD2 code reader disconnected before you start your vehicle’s engine.

Step 2: Inspect area

You then need to open your car’s hood and do away with your air cleaner assembly, and then go ahead and inspect the throttle plate as well as its entire surrounding. In case you notice there is a build-up of carbon on the throttle sensor, especially under the throttle plate, use a carburetor cleaner or a clean rug to clean up the build-up until it becomes spotless. Note that the build-up of carbon under the throttle sensor can make it stop working as required as well as hinder it from moving freely.

Step 3: Connect the Multimeter

Locate the TPS attached on the side of your throttle body, in case your TPS is connected to your reference voltage. Consequently, place the black test lead of your digital multimeter on the ground terminal of the TPS connector, and then turn on your ignition key without starting the car’s engine. After that, place the red read test leads of your meter placed to the remaining two terminals. The reading displayed on the terminal should be approximately around 5 volts, and this means that the terminal is generating the TPS voltage signal.

You must always note down the color of the wire that is placed on your terminal, with the 3rd wire usually equal to the signal wire. In case you do not get a reading of 5 volts, you should then know that the circuit has a problem that needs to be fixed as soon as possible. This gives you a reason to have the circuit examined for any damages. When you are done, switch off your ignition key and insert your electrical connector back to your TPS.

In case you TPS responds well by generating the appropriate signal voltage, remove the probe on the terminal of your TPS connectors, and this you can do easily using a pin.

Step 4: Connect to ground wire

When you are done, have both your red (positive) as well as black (negative) leads from your digital multimeter connected to your ground wire. After you are done switch on your ignition key and start the engine, after confirming that the throttle plate is closed completely, the reading value displayed on your multimeter should be approximately 0.2-1.5 volts depending on the model of your multimeter. If the reading is zero, ensure you are at a minimal setting, at either 20 or 10 volts, and if the reading remains the same, continue to run the test.

As you observe the reading being displayed on your digital multimeter, make sure the throttle plate is fully opened, and your multimeter reading is 5 volts. Additionally, the reading should increase the more you gradually open the throttle plate.

If you notice the voltage is stuck or it is skipping as you slowly open the throttle plate, then your TPS is likely not functioning correctly, and it needs to be replaced. This also applies when your TPS readout is not 5 volts or close to it. When you are done, switch off your ignition key as you remove your pins.

Conclusion

Having read through the article, you now know that testing the throttle sensor with a multimeter is easy, so long as you have the appropriate skills and knowledge. Therefore, by following the steps mentioned above carefully, you will be able to tell whether or not your throttle position needs to replaced or not. Once you know this, you will be able to get your engine running normally in no time.