The use of 3D printing technology is just starting to be adopted by many industries despite being around for decades. Companies are starting to use this technological innovation in an attempt to improve their business processes.

This has further been made more accessible, with 3D printing technology now more accessible than ever, even smaller enterprises. The reason for this is the falling cost of this innovative technology.

But which industries have fully adopted the use of 3D printers? If you’ve been asking yourself this question, here’s an outline of the various industries where 3D printing technology is being used due to its efficiency, accuracy, and reducing your time and expenditure.

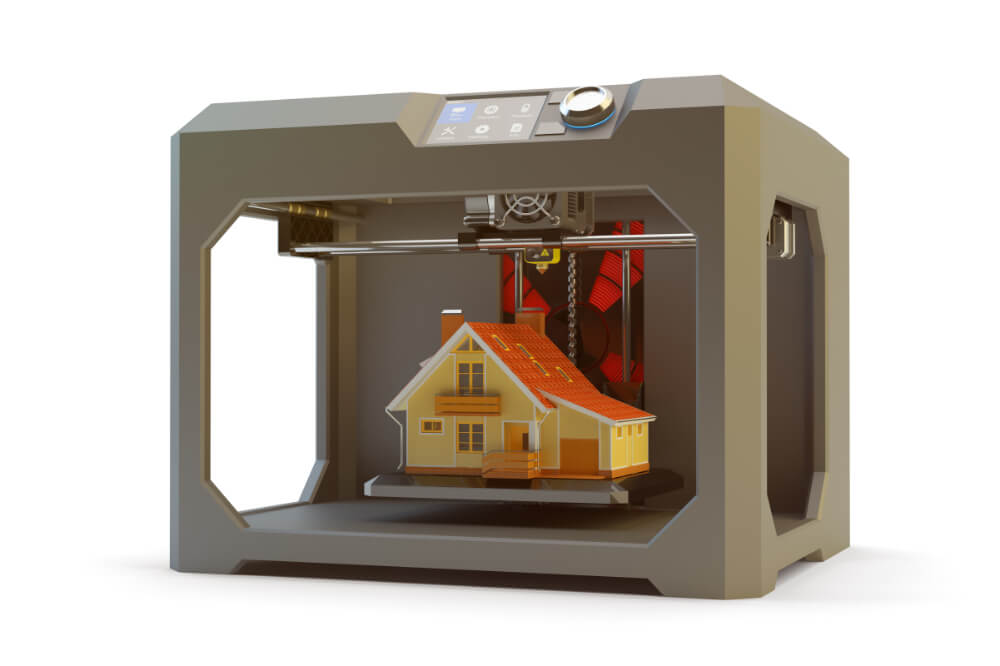

Architecture

Building models were designed either through handmade foam and wooden foam boards models or computer simulations. However, this is no longer the case thanks to 3D printing technology. This is because 3D printers are considered to be a lot more effective and accurate at designing complex architectural structures.

The designing of architectural 3D model structures involves FDM and PolyJet technology due to their detailed and exceptional quality printing capabilities. Using 3D printers, architects can now show their clients a refined building structure model.

Moreover, this technology helps lower the total cost of designing these models. As a result of the high-quality models, architects can now reinforce their relationship with their clients due to the guaranteed quality of all the products.

Education

Schools also aren’t being left behind in incorporating the use of 3D printers into their curriculum. It’s for this reason that 3D printers are now a common sight in public libraries and classrooms.

This is being done because 3D printing technology holds the key to future technological breakthroughs, so students need to understand how to use it. The students learn this by using cheap tooling to design and produce 3D models they can start using.

Students also learn about 3D printing badges, closing the gap from images and ideas on a screen or page. This consequently allows for the creation of the formation of images or ideas in a physical, 3-dimensional world.

Universities too, have started using 3D printers for conducting certain projects and classes. Other companies like MarketBot are providing certification courses to students and educators in the application of 3D printing.

The use of 3D printers is also revolutionizing the STEM education by designing affordable scientific equipment of fantastic quality from hardware designs. This technology is also providing students the ability to low-cost rapid prototyping in classrooms.

Therefore, 3D printing technology allows students to learn about many 3D printing applications by discovering architectural, engineering, and design principles. Subsequently, this allows the production of museum items such as historical artifacts and fossils in the class without risking the destruction of fragile collections.

Aerospace Industry

One of the earliest adopters of 3D printing technology are aircraft manufacturers because it allowed for a substantial reduction in costs. Other manufacturers opt to use titanium parts when printing modern 3D items, thereby saving millions in production cost per plane. The use of 3D printing technology has also been adopted since 3D printed parts used or engineering aircraft are lightweight.

In addition to reducing the production of airplane parts, 3D printing technology also allows the design of parts capable of withstanding exposure to dangerous chemicals and high temperatures. All this is done with ensuring the aircraft parts are lightweight, thus preventing individual part failure, which might lead to whole system failure.

Medicine

The world of medicine was also quick to embrace 3D printing technology across various uses. One of the most popular uses is in bioprinting, which entails the combination of biomaterials such as growth factors and cells to make tissue-like structures that resemble their natural equivalents.

This includes the printing of prosthetics, which best brings out the versatility of 3D printing. Thanks to 3D printers, it’s now possible to measure prosthetics and, consequently, model and print them at a much lower cost. Unlike in the past, where children had to wait before getting a new prosthetic to confirm they won’t outgrow it in the future, it’s now possible to print a new prosthetic after every couple of months.

The use of 3D printing technology has also been incorporated in the production of metal orthopedic implants. This is because of the 3D printing capabilities of making porous surfaces. As a result, this makes it easy to incorporate the kind of implants into the patients’ natural bones.

Moreover, 3D printing technology is useful in designing 3D printed tissues, making pharmaceuticals not only inexpensive but also ethical. This consequently helps in figuring out the safe dosages and any possible side effects.

Construction Industry

The use of 3D printers is also prevalent in the construction industry. It’s usually used in the building of bridges, concocted houses as well as bridges. The best part is everything is completed in a few days, which has made construction a lot easier.

3D printing technology is being used in the construction industry to offer homeless people a roof over their heads. This helps reduce the number of people across the globe who are homeless, even in the poorer countries. It’s thus evident that 3D printers play a vital role in achieving the global goal of making the world a more habitable place for everyone.

Automotive Industry

This industry is also among the forerunners pushing the use of 3D printers, especially high-end companies such as BMW and Audi. Other sub manufacturers and race car teams have also taken note of this and embraced this technology’s use. Some of the most common 3D printed automotive parts include prototypes, cradles, and fixtures.

3D printers are also being used in manufacturing replacement parts for vehicles that are centuries old. This is done to guarantee there are adequate pieces needed when servicing legacy be vehicles plus for standard operations, repairs, and maintenance.

Conclusion

The use of 3D printing technology, also known as additive manufacturing, has soared in the last few years. This fact has been proved with many industries, as those mentioned have above have quickly adopted this technology due to its affordability and efficiency. Therefore, this is enough proof as to why 3D printers are here to stay and will be a vital part of society in the future with continued innovations.