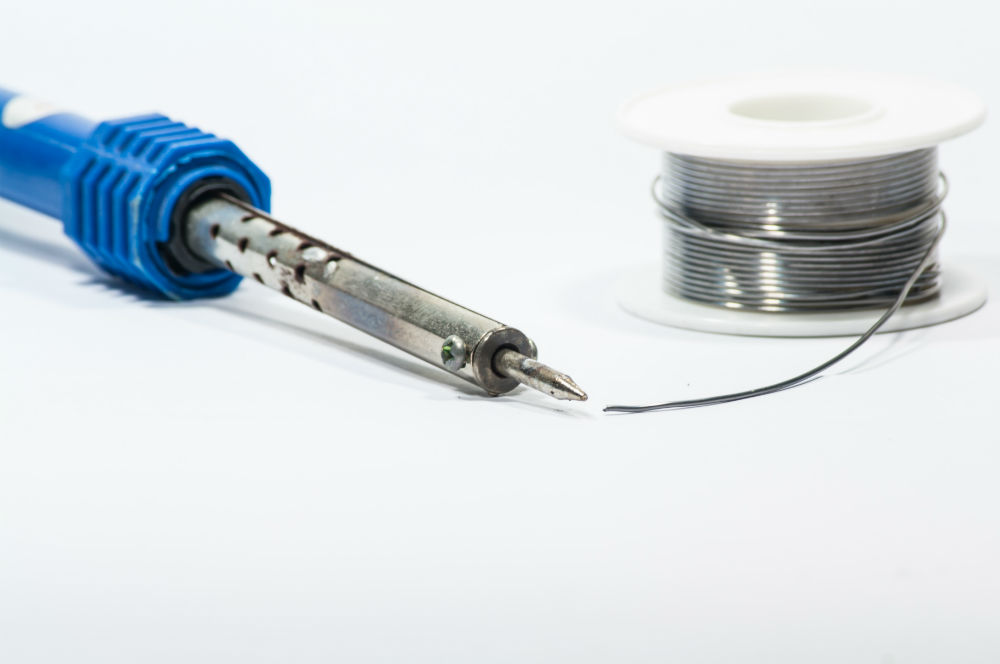

Soldering is a useful thing to know how to do to join small metal pieces, especially for a wide variety of electronics. There are lots of soldering irons out there, some better than others.

However, regardless of the quality, they will all encounter problems if you do not engage in regular cleaning and maintenance. The solder or metal you use builds up and damages the tip of any soldering iron, so it needs to be maintained.

In this article, we will discuss how to clean your soldering iron.

How to Clean a Soldering Iron: Step by Step

To be totally fair, cleaning a soldering iron, as well as maintaining it, is really not all that hard. As long as you perform these regular maintenance tasks every few weeks, or more or less depending on how much you use the soldering iron, you should be able to keep it in top condition for quite some time.

Related: Our Recommendations for a Great Soldering Iron

We are going to go over 3 main cleaning and maintenance methods here. First off, we are going to clean the soldering iron tip, then we will tin the tip, then we’re going to cover some basic maintenance too. So, let’s get started and clean your soldering iron tip.

Cleaning the Soldering Iron Tip

You need to clean the tip of the soldering iron. It’s pretty easily done and won’t take that long to complete, especially if you have the right tools on hand.

Keep in mind that you always need to let the tip of the soldering iron cool down before cleaning; you do not want to start this process if the soldering iron is still hot. Let it cool down for at least 15 minutes after the last use before you clean it. It’s all about being able to clean the soldering iron thoroughly without burning yourself.

When it comes to regular cleaning, you want to clean it every time after heavy use. It might not be necessary after light use, but to prevent heavy buildups over time, you need to clean it after every heavy use.

You will need a cellulose and sulfur-free sponge – this is what you will use to clean the tip of the soldering iron. Soak the sponge in water and rub it over the tip of the soldering iron for a couple of minutes.

You want to do this first to take care of mild buildup, plus it will help you figure out whether or not the tip is cool enough to touch with your bare hands. Keep in mind that a regular sponge will not be able to remove debris as effectively as the special sponge which we mentioned above.

Now you need to get yourself some steel wool. Dampen the steel wool using normal water and scrape off any remaining rust or buildup.

is something you might need to do if there is really heavy rusting and buildup on the tip, buildup which the sponge alone cannot remove. Don’t use sandpaper or anything else of the sort for this, only dampened steel wool.

Tinning the Soldering Iron Tip

After you have finished cleaning the soldering iron, you want to tin the tip. This process involves coating the tip of the soldering iron in a thin layer of solder. This will help protect the soldering iron from rusting, oxidization, and other forms of damage.

As a safety precaution, you should wear heat-resistant gloves and goggles, because when tinning, if you hit an air pocket, the chemical in the solder can spit solder into the air.

Recommended: Need a Good Soldering Iron for Guitar Repairs?

Let’s talk about how to tin the soldering iron tip right now. Technically speaking, you should do this after every heavy use and after cleaning to prevent damage.

Melt a small amount of solder over the tip of the soldering iron. Let it melt and then coat the tip with a very thin layer of the melted solder.

You want to apply it evenly in order to maintain regular heat flow and to prevent rusting and oxidization.

After having turned off the iron, cleaned it, and tinned it, you want to use an alloy cleaner on the whole tip of the soldering iron. Use a microfiber cloth to apply a thin layer of alloy cleaner. This will help to prevent dust buildup and will help to prevent further oxidization too.

Also Read: Soldering Station Recommendations

Cleaning Soldering Iron – Final Thoughts

As you can see, cleaning a soldering iron is not that hard, expensive, or time consuming. You only need a couple of tools and items to do the job.

However, be aware that this is important to do on a regular basis. Soldering irons are known to oxidize, rust, and just break down in general when not maintained the right way. It is a good idea to wipe down the tip with the appropriate sponge, even between soldering jobs.

One thing to keep in mind is that you always want to use high-quality solder when using your soldering iron. You don’t want there to be too many impurities in the solder being used as this will accelerate the rate of buildup and create rust.

You want the solder to be at least 50/50 or 60/40, with the first number being the amount of tin in the solder. Regular maintenance and high-quality solder are key to keeping your soldering iron in top condition.