When it comes to soldering iron, its usefulness will highly depend on the project you are working on along with the type of metal you will be working with. Not all metal is best for use with a soldering iron.

Different metals feature different compositions, which tend to have a significant impact on the soldering process and the type of soldering iron that will be best for that particular project.

Many novices tend to assume any soldering iron can be used in fixing any metal. However, as an individual who has tried soldering hard metals with an electric soldering iron will understand how untrue this is. With that said, can a soldering iron melt copper? Continue reading this article to find more about this particular question.

Soldering Copper

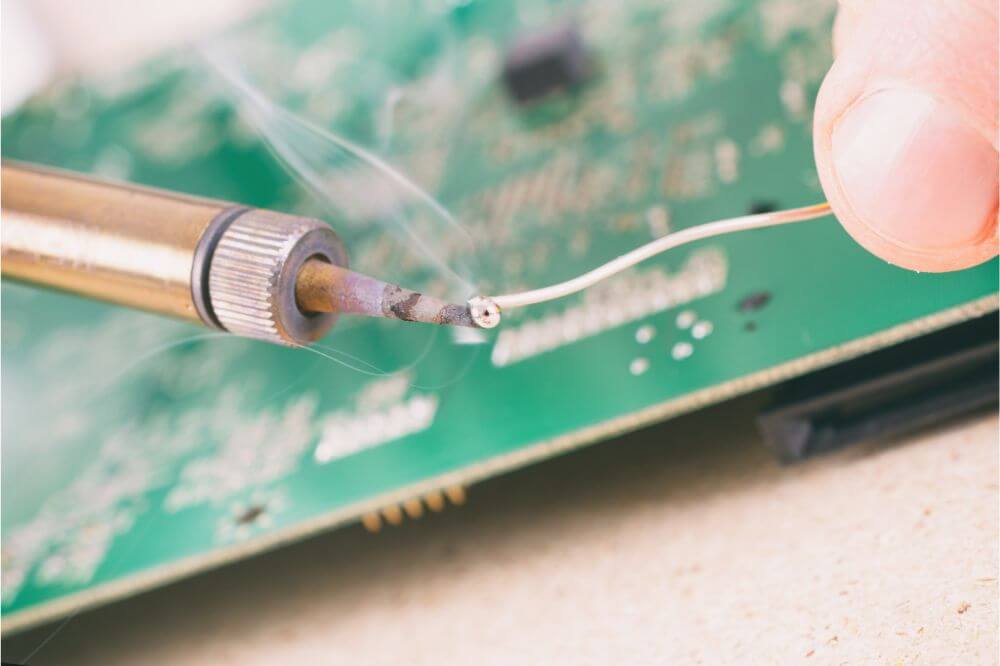

There are several electronic devices that require soldering skills. You can as well consider using soldering skills in creating a metal-work form of arts or objects. In addition to that, you can still use a soldering iron to fix toys and other electrical devices; however, you have to keep in mind the rules of soldering a copper wire. During this particular process, you need to be careful and very much attentive.

Whether you are soldering a circuit board or a piece of copper jewelry, the basics of soldering remain the same. To solder copper tubing using a soldering iron, you will need to have the following in mind;

Get the appropriate diameter of your copper tube.

Usually, a copper tube used in plumbing has an outside diameter of 0.125 inches. If you require to cut the copper tubing while working on your project, ensure that you use a tube cutter. Clamp your copper tubing properly and then rotate the cutter around the pipe. In most cases, this will take approximately eight turns.

Have the right thickness

Ensure that your copper tubing has the appropriate wall thickness for your project. Nominally-sized copper tubing is often available in four different weights and wall thickness, which are usually color-coded.

Solder

Before you start soldering your copper tubing, you will need to choose the right solder for the job. A lead-free solder will be best for use in the water system.

Since lead is a health hazard, you should avoid using it while soldering a potable water system. 95/5, which is 95% tin and 5% antimony solder or an alloy of tin and a small amount of copper or silver, will be best for soldering copper tubing.

Flux

Just like solder, you will need the perfect flux for this particular project. Flux is ideal for cleaning and covering the surface of copper before being assembled and soldered. Upon heating, flux helps in facilitating further cleaning of the copper tubing. It does this by eliminating atmospheric oxygen, preventing re-oxidation, and helps wetting out your solder.

Heat source

An electric soldering iron will not be hot enough to work with your copper tubing. This means that you will require a heat source that will offer sufficient output.

The heat source has to heat the assembled copper tubing and fittings to a temperature that is above the filler solder melting point. Typically, it has to be between 400 and 500 degrees Fahrenheit. As a result, you might consider using an acetylene/air or propane/air torch with the right tip for effectiveness.

Soldering Copper Tubing Step-By-Step

You will have to follow these steps while soldering copper tubing:

Preparing copper tubing

Get rid of the oxide coating on your copper tubing. You might consider using sandpaper, emery cloth, or any device specially designed for this purpose to achieve this.

The oxidized layer has to be removed thoroughly and ensure that there is no grease, dirt, or oil along with other impediments that will affect the wetting of your solder. If you don’t, you will end up having a leaky joint on the tubing

Use flux

Once you clean the copper from oxidation, you brush with a solder flux soon after you clean. After that, you will assemble your tubing and fitting. Always apply the flux both outside and inside of the copper.

Melting the solder

Move your solder and the source of heat to the opposite side of the melted solder. You will then continue feeding the joint with a small amount of solder as you continue soldering the metal until your solder has entirely circled the fitting.

Get rid of excess solder

Once you are through, you will get rid of the excess solder in your copper while still hot. It would be best if you considered using a clean, dry cotton rag. To freeze the solder, you can spray a mist of water; this will help in preventing the movement of your new joint that might create a leak.

What You Need To Know When Soldering A Copper

When it comes to soldering a copper pipe, you should always ensure that the soldering material should have a lower melting point than copper. If not, the copper tube will end up melting before your solder does. This is a vital aspect you will need to factor.

Compared to other metals, soldering copper is relatively easy, and even a rookie can learn the whole process in no time. To achieve a perfect joint, you will have to adhere to the basic guidelines discussed above.

Final Thoughts

As we come into conclusion, you should keep in mind that a soldering iron does not produce the required temperature to solder copper. As a result, a propane torch is often considered as the best option.

With a propane torch, heating a copper pipe to the required temperature is relatively easy compared to a soldering iron. However, the whole process is relatively easy when working with the right tool.

Always remember to get rid of the oxidized layer before working on your copper tubing. This will help in preventing any possible leakage in the future and promote a strong and reliable joint.

It would be best if you got rid of the oxidized layer from both sides that is inside and outside your copper pipe. As we conclude, we hope that this article has helped you answer the question; can soldering iron melt copper?